Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RPG. Revista de Pós-Graduação

versão impressa ISSN 0104-5695

RPG, Rev. pós-grad. vol.17 no.1 São Paulo Jan./Mar. 2010

ARTIGOS CIENTÍFICOS

Effect of light-curing units and glass fiber reinforcement on flexural strength of direct and laboratory-processed composites

Análise in vitro da resistência fluxural de uma resina composta direta e uma resina laboratorial de segunda geração associadas ou não a fibras de reforço

PRISCILA PAIVA PORTERO I; MATHEUS COELHO BANDÉCA I,II; RAFAEL GOMES DITTERICH III; PATRÍCIA GRAU GRULLÓN III; JORIM SOUSA DAS VIRGENS FILHO III; OSNARA MARIA MONGRUEL GOMES III

I Department of Restorative Dentistry of School of Dentistry of Universidade Estadual Paulista "Júlio de Mesquita Filho" (UNESP) – Araraquara/SP

II Department of Restorative Dentistry of School of Dentistry of University of Toronto – Toronto, Canada

III School of Dentistry of University of Ponta Grossa – Ponta Grossa/PR

ABSTRACT

The aim of this study was to evaluate in vitro the flexural strength of direct composite resin (Z-250 FiltekTM - 3M/ESPE) and second-generation laboratory composite (II CeseaDST - Kuraray) associated or not with glass fibers (Fibrex-coronal - Angelus), changing the curing light source (L.E.Demetron 1 - Kerr and Strobolux - EDG). Fifty-six specimens of the composites F and C were constructed using a stainless-steel split ring molds and divided into eight groups: GI – Composite Z-250/ No fiber/LED; GII – Composite Z-250/No fiber/Strobolux (STR); GIII - Composite Z-250/Fibrex-coronal (FBC)/LED; GIV - Composite Z-250/FBC/STR; GV – Composite CeseaDST II/No fiber/LED; GVI - Composite CeseaDST II /No fiber/STR; GVII - Composite CeseaDST II/FBC/ LED; GVIII - Composite CeseaDST II/FBC/STR. The specimens were subjected to the flexural strength in a universal testing machine equipped with a cell load of 500Kgf at a crosshead speed of 1±0.5 mm/min. The data were submitted to Tukey's Test (p = 0.01). The mean of flexural strength was in MPa: GI – 187,91 ± 32,78; GII – 196,76 ± 31,15; GIII – 208,27 ± 18,79; GIV – 218,02 ± 15,76; GV – 101,72 ± 11,25; GVI – 103,05 ± 9,56; GVII – 164,76 ± 12,54 e GVIII – 176,75 ± 47,03. The direct composite showed the highest flexural strength values in all groups; the light source did not affect the flexural strength of the composites; fiber reinforcement increased the flexural strength of both composites; however this increase was statistically significant only for the laboratory-processed composite.

Descriptors: Curing lights, dental. Flexural strength. Composite resins.

RESUMO

O objetivo deste estudo foi avaliar in vitro a resistência flexural da resina composta direta (FiltekTM Z-250 – 3M/ESPE) e da resina laboratorial de segunda geração (CeseaDST II – Kuraray) associadas ou não a fibras de vidro (Fibrex-coronal – Angelus), variando a fonte de luz fotoativadora (L.E.Demetron 1 – Kerr e Strobolux – EDG). Foram confeccionados 56 corpos de prova (CP) em uma matriz metálica bipartida com as dimensões de 13,0 mm de diâmetro por 2,4 mm de espessura divididos em 8 grupos (n=7) de estudo: GI – Resina FiltekTM Z-250/sem fibras/ LED; GII – Resina FiltekTM Z-250/ sem fibras/ Strobolux; GIII - Resina FiltekTM Z-250/ Fibrex-coronal/LED; GIV - Resina FiltekTM Z-250/Fibrex-coronal/ Strobolux; GV – Resina CeseaDST II/ Sem fibras/ LED; GVI - Resina CeseaDST II/ sem fibras/strobolux; GVII - Resina CeseaDST II/ Fibrex-coronal/ LED; GVIII - Resina CeseaDST II/ Fibrex-coronal/ Strobolux. Os CP foram submetidos ao teste de resistência flexural biaxial no equipamento Kratos com velocidade de 1±0,5 mm/min. e célula de carga de 500 Kgf. Os valores de resistência flexural foram submetidos ao teste de Tukey (p = 0,01). A média dos resultados em MPa foram: GI – 187,91 ± 32,78; GII – 196,76 ± 31,15; GIII – 208,27 ± 18,79; GIV – 218,02 ± 15,76; GV – 101,72 ± 11,25; GVI – 103,05 ± 9,56; GVII – 164,76 ± 12,54 e GVIII – 176,75 ± 47,03. Concluiu-se que os compósitos avaliados apresentaram diferentes comportamentos in vitro; o compósito direto FiltekTM Z-250 apresentou maiores valores de resistência flexural em todos os grupos estudados; o tipo de fonte de luz não interferiu na resistência flexural dos compósitos avaliados; o reforço com fibras aumentou a resistência flexural de ambos os compósitos avaliados, sendo que apenas para o compósito indireto CeseaDST II esse aumento foi significante.

Descritores: Luzes de cura dentária. Resistênica à flexão. Resinas compostas.

Introduction

The use of fibers to improve the mechanical properties of laboratory-processed composites from second generation has been recommended for several dental applications, including inlays, onlays, crowns and fixed partial dentures7.

Several types of fibers have been used as frameworks, such as carbon fiber, kevlar, aramida, nylon, polyethylene and glass fibers2. These two latter are the most commonly employed due to their translucency and ability to match the natural teeth. The recent developments in fiber reinforcement technology have allowed clinicians to manufacture crowns without the need of a metallic framework7. From an esthetic point of view this is a huge advantage compared to metal-ceramic restorations.

Laboratory-processed composites are usually light activated. The polymerization can be associated or not to the secondary polymerizing, such as additional light, heat and/or pressure1-4,8-12. Besides the conventional quartz-tungsten-halogen lights, other devices based on light-emitting diodes were recently introduced for dental applications3,4,8,9.

The flexural strength is the mechanical property that most resembles the stress at which materials are subjected in clinical scenarios, since tension, compression and shear stresses generally occur simultaneously. It is not common to observe these strain forces isolated. The flexural strength, stiffness, wear resistance and esthetic properties of a given veneering composite are the properties responsible for the effectiveness of the fiber-reinforced composites (FRCs) in the restorative dentistry1.

In dentistry, the use of FRCs are relatively recent12, therefore studies should be conducted in order to verify whether or not fiber-reinforcement is required for laboratory-processed and direct composites when used as frameworks of crowns. The method of polymerization used for light polymerizing is also relevant14,15. Secondary polymerizing requires specific equipments, increases the number of laboratorial steps and the treatment costs for patients.

The light-curing units have been widely used to photo-activation of dental materials4,5. The LED system have a semi-conductors used for light emission with a peak around 470 nm, which matches the optimum absorption wavelength to camphoroquinone15.

The use of xenon stroboscopic has been widely used to photo-activation of laboratory materials as composite resin. Others studies have been used others light units as the laser in dentistry, nevertheless good results have been reported only for preparing of dental surface4,5.

The present study aimed to evaluate the biaxial flexural strength of a direct composite resin and a laboratory-processed composite either reinforced or not with glass fibers when light polymerized with two different light sources.

Materials and methods

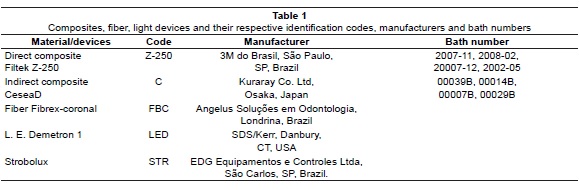

The materials/devices tested, brand names, identification codes, and manufacturers are listed in Table 1. Fifty-six specimens (13 mm diameter and 2.4 mm thickness) were made using a metallic mold (modified ISO 6872). The modification of the ISO 6872 was made to obtain specimens with similar dimensions of premolars crowns.

The metallic mold was placed on a sheet of polyethylene supported by a glass slab for GI. The composite resin (Z-250) was placed into the mold using a metallic spatula Thompson #6 (Hu-Friedy, Leimen, Germany).

A second sheet of polyethylene was packed over the material and another glass slab placed on top. The glass slab was removed and light-activated with LED (11 mm tip, S/N 10921561) for 7.5 minutes at 800 mW/cm2. The power density was measured with a radiometer (Demetron Research Corp., CT, United States).

The specimens were polished using 600-grit silicon carbide paper in a low-speed handpiece (Arbor Brands; Buffalo Dental Mfg, Syosset, New York).

The same procedures were made for GII, however the specimens were light-activated with a xenon stroboscopic device (STR) for 7.5 minutes. Specimens of GIII were manufactured using composite resin (Z-250) and multidirectional pre-impregnated glass fibers (FBC). The metallic mold was placed on a sheet of polyethylene supported by a glass slab. A thin layer of adhesive (Adesivo-C, Angelus Soluções em Odontologia, Londrina, PR, Brazil; batch #2079) was applied in the interior of the metallic mold.

The pre-impregnated fibers were positioned in the metallic mold. The composite resin (Z-250) was placed inside the mold. Then, a second sheet of polyethylene was packed over the material and another glass slab placed on top. The specimens were light-activated with LED for 7.5 minutes and polished using silicon carbide paper in a low-speed hand piece. Specimens from GIV were manufactured in the same way as GIII, except the light polymerizing procedure that was performed with the STR.

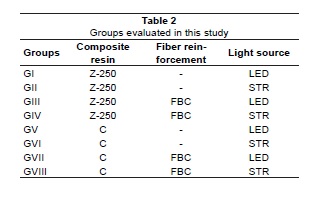

Specimens from GV to GVIII were manufactured in the same way as specimens from GI to GV, respectively. However, the composite employed was the second-generation laboratory-processed composite C in the GV to GVIII. The eight experimental groups (n = 7) 7) from this study are displayed in Table 2.

The dimensions of all specimens were measured with a digital caliper (Mitutoyo Sul Americana, Suzano, SP, Brazil) and specimens with defects were excluded from the study. The specimens were kept stored in distilled water in a dark environment at 25°C for 24 hours before testing.

Each specimen was placed centrally on a metallic device, which was fixed by three spheres 2.8 mm in diameter. The distance between the centers of each pair of spheres was 8.6 ± 0.1 mm. The specimens were then loaded (cell load of 500 Kgf) to failure via a small stainless steel ball (1.4 ± 0.1 mm in diameter) inserted at the end of a pin which was held in the crosshead of the universal testing machine Kratos (Model MP Series M040801, Dinamômetros Kratos Ltda., São Paulo, SP, Brazil) at a speed of 1 ± 0.5 mm/min until permanent deflection or fracture. As specified by the ISO 6872, a constant crosshead speed of 1 ± 0.5 mm/min is required for testing. After testing, the biaxial flexural strengths11 were calculated from the following formula, recommended by the ISO 6872:

S = - 0.2387 P(X-Y)/d2

where:

S = Strength in MPa

P = Load in Newtons

X = (1+v) In(r2/r3)2 + [(1-v)/2] (r2/r3)2

Y = (1+v) [1+In(r1/r3)2] + (1-v) (r1/r3)2

where:

v = Poison's rate = 0.25

r1 = Radius of the ring support in mm

r2 = Radius of the loading sphere in mm

r3 = Radius of the specimen in mm

d = Thickness of the specimen in mm

Statistical analysis

The normality of the data was tested using the Shapiro-Wilk test. The results were then submitted to a three-way analysis of variance and Tukey's test for pairwise comparison. The analysis was conducted with an alpha level of significance of 0.01, which is more conservative than the traditional alpha level of 0.056.

Results

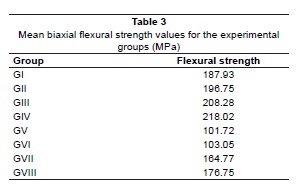

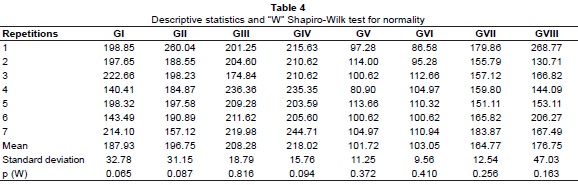

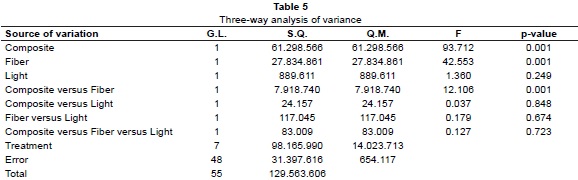

The mean flexural strength values (MPa) are depicted in Table 3. The Shapiro-Wilk test showed a normal distribution of the data (Table 4). The three-way analysis of variance (Table 5) showed that the main factors composite and the fiber reinforcement were statistically significant as well as the interaction of these two factors (composite versus fiber) (p < 0.01).

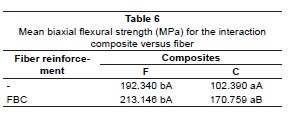

The main factor light and its respective interactions (light versus composite; light versus fiber) were not statistically significant. Table 6 demonstrates that the use of fiber reinforcement with the composite F allowed the achievement of the highest mean biaxial flexural strength, although this value was not statistically different from the composite F with no fiber reinforcement. However, for the composite C, the use of fibers increased the biaxial flexural strength values (p < 0.01; Tukey's test). The composite F showed higher flexural strength means than the composite C even when the latter was reinforced with glass fibers.

Discussion

In this study the biaxial flexural strength of two types of composites and the effect of the addition of fibers and the type of polymerization over this properties were investigated. The data obtained under the conditions of this study demonstrated that the evaluated fibers increased the biaxial flexural strength of only one of the composites studied, the composite C, which is a laboratory-processed composite. We also verified that the light source did not affect these mechanical properties in the materials.

Ramos Junior et al.12 demonstrated that fiber reinforcement within a composite increased the fracture strength and also prevented the fragments to separate itself. These results are not in agreement with the present investigation, since only the flexural strength of the laboratory-processed composite C was increased with the fiber reinforcement.

Bottino et al.2 evaluated the mechanical properties of two direct composites (Charisma, Heraeus Kulzer – Germany and Permalute, Ultradent Products Inc.) and demonstrated that although the addition of Ribbond fiber (Ribbond Inc.) increased the flexural strength of the composites, the composite material also plays an important role on the flexural strength of fixed partial dentures. A considerable increase in the flexural strength mainly for the Charisma composite was observed in the aforementioned study, which corroborates with the present findings. In this study the multidirectional FBC increased the flexural strength of the evaluated composites; however this increase was much higher for the C laboratory-processed composite.

In accordance to our results, since in this study the direct resin F showed higher flexural resistance values than the indirect resin C, when associated or not to reinforcement fibers, the filler loading, monomer system and the conversion degree affect the flexural strength of composites3. This is the rationale for testing the microhybrid F and the second generation laboratory-processed composite C after polymerizing with different light sources (LED and STR).

In the present results since fiber reinforcement increased significantly the flexural strength of the composite C, without fiber reinforcement, the laboratory-processed composite C showed low flexural strength values.

One could expect that indirect composites activated with a high light intensity device would have higher mechanical properties due to a high conversion of monomers to polymers and increased cross-linking8. Apart from higher physical and mechanical properties, high wear strength would also be expected.

Miyazaki et al.10 investigated the polymerization features of light-polymerized composites and their relation to some mechanical properties. They have concluded that the flexural strength is strongly affected by inadequate polymerization. According to the results of this investigation, no significant differences in the flexural strength means were observed when the composites were light-polymerized with light-emitting diodes and a xenon stroboscopic device.

Swartz13 reported that the conversion degree of laboratory-processed composites is significantly higher than the direct composites, which is in turn reflected by its superior mechanical properties. However, this statement was not supported by our results. The laboratory-processed composite C showed lower flexural strength than the direct composite F when light-polymerized either with the xenon stroboscopic or LED light.

Leinfelder8 claimed that the xenon stroboscopic device increases the polymerization degree of composites. According to the author, the short excitation period followed by the long period with no light exposure allows partial relaxation of the polymer network and therefore more double carbon bonds becomes available for the polymerization reaction. This is not in agreement with our results since similar flexural strength means were observed when the light polymerizing was performed with the LED and xenon stroboscopic lights.

It is widely known that an inadequate polymerization has detrimental effects on some properties of composites such as strength, toughness, color stability, hardness and wear strength. The excitation of composites with an appropriate wavelength and enough light intensity is essential to achieve an adequate conversion degree of light-polymerized composites. Besides that, the association between light source and composite can also play an important role on the properties of veneering composites14.

According to Matsumura et al.9 and Tanoue et al.14, the use of light polymerizing device with high light intensity can increase the hardness, compressive strength, flexural modulus and also reduce the water sorption/solubility of composites. The results from the present investigation suggest that the conversion degree of the composite C was lower than the F, since the former showed the lowest values of flexural strength in all groups. The lower performance of C can also be attributed to a lower amount of photo-initiator system or a higher concentration of inhibitor, which is usually used to increase the composite shelf-life, as reported by Tanoue et al.15.

Palin et al.11 investigated the confidence of biaxial and three-point flexural strength tests using the composite F light polymerized with either a quartz-tungsten-halogen light (XL2500 -3M/ESPE) or a light polymerizing device (Visio-Beta – 3M/ESPE). The authors have not observed any significant difference on the biaxial flexural strength values after polymerizing with one of the two mentioned methods. This corroborates with the results of the present investigation, in which specimens light polymerized with LED or STR were statistically similar one to another.

The results of this investigation suggested that the direct composite F is appropriated for fabrication of metal-free premolar crowns when compared to the laboratory-processed composite C.

Further studies involving flexural strength and other mechanical properties should be conducted with other fiber systems, composites and light polymerizing units, since different results can be obtained varying one of the aforementioned factors.

Conclusion

The evaluated composites showed different in vitro behavior; the direct composite F showed the highest flexural strength means in all groups; the light source did not affect the flexural strength of the composites; the fiber reinforcement increased the flexural strength of both composites, however this increase was only statistically significant for the laboratory-processed composite C.

References

1. Ban S, Anusavice KJ. Influence of test method on failure stress of brittle dental materials. J Dent Res.1990;69(12):1791-9. [ Links ]

2. Bottino MA, Quintas AF, Bondioli IR. A comparative study of flexural strength using two composites resins fiber reinforced. PGR:Pós-Grad Rev Fac Odontol. 2001;4(3):5-12.

3. Braga RR, Cesar PF, Gonzaga CC. Mechanical properties of resin cements with different activation modes. J Oral Rehabil. 2002;29:257 -62.

4. Calixto LR, Bandéca MC, Silva FB, Rastelli ANS, Porto-Neto ST, Andrade MF. Effect of light-curing units on push-out fiber post bond strength in root canal dentin. Laser Phys. 2009;19:1867-71.

5. Calixto LR, Lima DM, Queiroz RS, Rastelli ANS, Bagnato VS, Andrade MF. Curing depth of composite resin light cured by LED and halogen light-curing units. Laser Phys. 2008;18:1365-9.

6. Campanha NH, Pavarina AC, Vergani CE, Machado AL. Effect of microwave sterilization and water storage on the Vickers hardness of acrylic resin denture teeth. J Prosthet Dent. 2005; 93(5) :483-7.

7. Freilich MA, Meiers JC, Duncan JP, Goldberg AJ. Fiber-reinforced composites in clinical dentistry. Chicago: Quintessence; 2000.

8. Leinfelder KF. New developments in resin restorative systems. J Am Dent Assoc. 1997; 128:57 3-81.

9. Matsumura H, Tanoue N, Atsuta M, Kitazawa S. A metal halide light source for laboratory curing of prosthetic composite materials. J Dent Res. 1997;7 6:688-93.

10. Miyazaki M, Oshida Y, Moore BK, Onose H. Effect of light exposure on fracture toughness and flexural strength of light-cured composites. Dent Mater. 1996;12:328-32.

11. Palin WM, Fleming GJ, Marquis PM. The reability of standardized flexure strength testing procedures for a light-activated resin-based composite. Dent Mater. 2005; 21:911-9.

12. Ramos V Jr, Runyan DA, Christensen LC. The effect of plasmatreated polyetilene fiber on the fracture strength of polymethil methacrylate. J Prosthet Dent. 1996;7 6:94-6.

13. Swartz ML. Reaction and discussion. Use of laboratory fabricated resin restorative material. In: Symposium on Esthetic Restorative Materials. Chicago, 1991. p. 70-7.

14. Tanoue N, Matsumura H, Atsuta M. Curing depth of a composite veneering material polymerized with seven different laboratory photo-curing units. J Oral Rehabil. 1998;25: 199-203.

15. Tanoue N, Matsumura H, Atsuta. Properties of four composite of four composite veneering materials polymerized with different laboratory photo-curing units. J Oral Rehabil. 1998;25:358-64.

Endereço para correspondência:

Matheus Bandéca

Universidade Estadual Paulista "Júlio de Mesquita Filho"

Department of Restorative Dentistry

Humaitá St., 1680

CEP 14.801-903 – Araraquara/SP

e-mail: matheus.bandeca@utoronto.ca

Recebido em: 10/11/09

Aceito em: 07/01/10