Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RPG. Revista de Pós-Graduação

versão impressa ISSN 0104-5695

RPG, Rev. pós-grad. vol.18 no.2 São Paulo Abr./Jun. 2011

ORIGINAL ARTICLE

Roughness and porosity of provisional crowns

Rugosidade e porosidade de coroas provisórias

Daniel Afonso HiramatsuI; Rafael Tobias Moretti-NetoII; Bruna Fidêncio Rahal FerrazI; Vinícius Carvalho PortoIII; José Henrique RuboIV

IMSc, Graduate Student from Department of Prosthodontics, School of Dentistry of Bauru, University of São Paulo – Bauru/SP, Brazil.

IIPhD, Professor from Department of Clinics and Surgery, School of Dentistry, Federal University of Alfenas – Alfenas/MG, Brazil.

IIIPhD, Professor from Department of Prosthodontics, School of Dentistry of Bauru, University of São Paulo – Bauru/SP, Brazil.

IVPhD, Professor and Chair from Department of Prosthodontics, School of Dentistry of Bauru, University of São Paulo – Bauru/SP, Brazil.

ABSTRACT

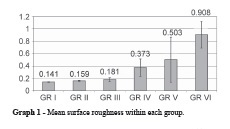

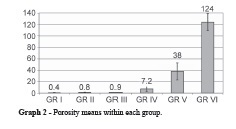

This study aimed at evaluating the surface roughness and porosity of an acrylic resin used for provisional crowns. Six different processing techniques (direct and indirect) were assessed: (I) heat-cured acrylic resin under pressure; (II) heat-aided autopolymerizing resin under pressure; (III) autopolymerizing resin under pressure; (IV) bead-brush technique; (V) autopolymerizing resin in sandy stage; (VI) autopolymerizing resin in plastic stage. Twelve specimens were made for each test group. Roughness was evaluated with a rugosimeter, and pore quantification was performed using a stereoscopic magnifying lens. The highest mean surface roughness (Ra = 0.908 mm) was measured for Group VI. The lowest surface roughness value (Ra = 0.141 mm) was determined for Group I. Significant differences in mean surface roughness were found between direct and indirect techniques. Direct techniques reached the highest roughness and porosity values; its use should be restricted to avoid creating favorable conditions for microorganism proliferation.

Descriptors: Dental restoration, temporary. Tooth crown. Dental prosthesis.

RESUMO

Este estudo visou avaliar a rugosidade e porosidade de uma resina acrílica usada para coroas provisórias. Seis técnicas diferentes de processamento (diretas e indiretas) foram avaliadas: (I) termopolimerização sob pressão; (II) polimerização auxiliada por calor e sob pressão; (III) autopolimerização sob pressão; (IV) técnica do pincel; (V) autopolimerização da resina com inserção na matriz na fase arenosa; (VI) autopolimerização da resina com inserção na matriz na fase plástica. Doze espécimes foram feitos para cada grupo de teste. A rugosidade foi avaliada com um rugosímetro e a quantificação de poros foi feita usando-se uma lupa de aumento estereoscópica. A maior média de rugosidade (Ra = 0,908 mm) foi medida no Grupo VI. A menor média de rugosidade (Ra = 0,141 mm) foi determinada no Grupo I. Diferenças significantes na média de rugosidade foram encontradas entre as técnicas diretas e indiretas. As técnicas diretas alcançaram valores mais altos de rugosidade e porosidade; seu uso deve ser restringido a fim de evitar a criação de condições favoráveis à proliferação de microorganismos.

Descritores: Restauração dentária temporária. Coroa dentária. Prótese dentária.

INTRODUCTION

The prosthodontic treatment of partially edentulous patients often requires a long-term provisional stage that makes possible to the professional to foresee the success of the final restoration in its mechanical, aesthetic and functional aspects. Provisionals can be made either chair side (direct technique) or with the help of a dental laboratory (indirect technique)16. According to the technique used, the processing of acrylic resins to make the provisional crowns can result in a surface that presents more or less roughness and porosity.

Porosity is an undesirable consequence of the processing and polymerization of acrylic resins. This is a complex phenomenon of multifactorial origin related to the vaporization of monomer, lack of uniformity of the acrylic resin mixture or lack of adequate pressure during the polymerization process14.

Rough and/or porous surfaces on provisional crowns can create favorable conditions for the proliferation of microorganisms, especially those responsible for caries and periodontal diseases. Those microorganisms can only survive in the oral environment if they can cling onto surfaces that present favorable conditions as well as protection against removal forces2,4-7,9,11-13,17. For these reasons, surface roughness of other restorative materials has also been subject of study10.

OBJECTIVES

The objective of this study was to analyze the roughness and porosity produced by different techniques of acrylic resin processing, and verify possible differences among them.

MATERIAL AND METHODS

A total of 72 acrylic resin specimens were fabricated with poly (methyl methacrylate) resin (Dencor, Artigos Odontológicos Clássico Ltda., São Paulo, Brazil), shade 66. The samples were divided in six different groups, with 12 specimens each, according to the following processing techniques: Group I – heat-cured acrylic resin under pressure; Group II – heat-aided autopolymerizing resin under pressure; Group III – autopolymerizing resin under pressure in silicone matrix; Group IV – bead-brush technique with autopolymerizing resin; Group V – pouring autopolymerizing resin (sandy stage) in a silicone matrix; Group VI – pouring autopolymerizing resin (plastic stage) in a silicone matrix.

Preparation of acrylic resin specimens

Wax blocks measuring 20 x 10 x 3 mm were used to obtain the specimens. For Groups I and II, the wax blocks were included in flasks to form the molds. For groups III to VI the wax blocks were included in condensation silicone (Zetalabor, Zhermack S.p.A, Italy) to create the matrix.

Except for group IV (bead-brush technique), the mixing proportion used was: 1.50 g of polymer, measured by weight in a high precision scale (0.001 g precision) and 0.70 mL of monomer, measured by volume with a pipette (equivalent volume ratio 3:1 as indicated by the manufacturer). The liquid and the powder were dispensed in a Dappen dish and smoothly mixed for five seconds.

Group I: 12 wax blocks were flasked with dental stone (Durone IV, Dentsply, Rio de Janeiro, Brazil), according to conventional procedures. After the stone was set, the wax was removed and the acrylic resin was manipulated (heat-polymerizing resin). When the plastic stage was reached (1.5 to 2 minutes after saturation in Dappen dish), the resin was inserted into the flasks. The flasks were then taken to a hydraulic press and immersed in cold water under pressure (3 x 105 N/m2) and heated to 70°C. This temperature was maintained for 2 hours. Deflasking was performed by routine laboratory procedure.

Group II: flasking was made as previously described for Group I, but using autopolymerizing resin. The temperature (70°C) was maintained for only 15 minutes; cooling and deflasking were the same as for Group I.

Group III: the specimens were made by manipulating the acrylic resin in a Dappen dish and pouring it in the silicone mold. This mold was placed against a plaster platform and stabilized with rubber bands. The mold and plaster platform set was immersed in water under pressure (3 x 105 N/m2) at 70°C for 15 minutes.

Group IV: acrylic monomer and polymer were dispensed in separate Dappen dishes in order to use the bead-brush technique. The tip of the brush was wet in the liquid and put in contact with the powder. The resin was continually taken to the interior of the silicone mold until the mold was completely filled.

Group V: for this group the liquid was saturated with the powder until reaching a smooth texture. The mold was filled with the acrylic resin immediately after saturation, in its sandy stage.

Group VI: the liquid was saturated with the powder until reaching a smooth texture. The resin was allowed to reach its plastic stage (1.5 to 2 minutes after mixing) keeping a glass slab on top of the Dappen dish to avoid excessive monomer evaporation. Then, the acrylic resin was inserted into the mold with a spatula.

Finishing and polishing

Specimens were finished in a lathe (APL 4, Arotec, Cotia, Brazil) using a sequence of 400, 600, 800 and 1,200 grit wet sandpaper3,8,15. The goal of this stage was to standardize the surfaces of the specimens before the roughness and porosity readings.

The surface roughness (Ra) was verified in a Hommel Tester T1000 basic rugosimeter (Hommelwerke GmbH ref. #240851, Schwenningem, Germany). Six readings per specimen were taken, three longitudinal and three transversal to the long axis3,15.

To facilitate the porosity readings, the specimens were immersed in Nankin ink for 2 hours, then rinsed in running water for 10 seconds and dried with tissue paper. To delimitate the reading area, a metallic device containing 3 circular orifices 0.5 cm in diameter (area = 20 mm2), was placed over the specimens. The number of pores in each area was determined with a stereoscopic magnifying lens (63X magnification). Data were submitted to one-way analysis variance (ANOVA) and to Tukey’s test (t-test) at a 5% significance level and to the Pearson linear correlation test.

RESULTS

The highest mean roughness values were obtained with the direct techniques (Groups V and VI); these values were significantly higher than the means obtained by indirect techniques (Groups I, II and III). The bead-brush technique presented an intermediary value, not significant when compared to Groups I, II and III, similar to Group V and different from Group VI (Graph 1).

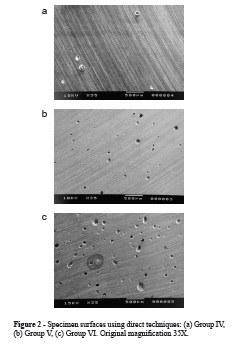

Regarding porosity, the highest mean number of pores per area was observed in Group VI, followed by Group V. Groups I, II, III, IV presented the lowest means, with no statistical difference among them (Graph 2). Figures 1 and 2 are scanning electron micrographs representative of the porosities present in the specimens. The Pearson linear correlation test (r) for roughness and porosity was 0.965, suggesting a positive correlation from strong to perfect.

DISCUSSION

A porous surface will present more irregularities, depressions and ditches, which can contribute to higher roughness values8. This correlation can be observed in the present study, since the specimens that presented the highest roughness values were also the most porous and vice versa.

The six Groups evaluated represent the most commonly used techniques for making provisional crowns, half of them being representative of laboratorial indirect techniques (Groups I, II, III) and half being representative of direct (chair side) techniques (Groups IV, V, VI).

Regardless of the technique used, provisional crowns have to be relined to ensure good adaptation. That is usually made by the bead-brush technique, resulting in a critical cervical area formed by increments of resin whose roughness/porosity characteristics resemble that of Group IV. The results for this Group did not present a statistically significant difference concerning roughness and porosity when compared to Groups I, II and III, even though numerically higher.

The same cannot be said about Groups V and VI, whose specimens were made according to another direct technique also commonly used. What made these two Groups different was the stage the resin was placed into the mold: sandy stage for Group V and plastic stage for Group VI. Considering that these two techniques can also be used for provisional crown relining and repairing, these two Groups presented unacceptable roughness and porosity values and therefore the use of these techniques should be avoided. The bead-brush technique should be selected in cases of relining and repairing instead. Undoubtedly, the direct techniques, even though saving laboratorial work need more clinical time and also presented the worst results for the properties assessed in this study.

One of the causes of internal porosities is the vaporization of the low molecular weight monomer or polymers at the thickest portions of dentures, where the temperature of the resin reaches the boiling point of these substances14. This fact helps understand the lower porosity and roughness results obtained by Group IV (bead-brush technique) when compared to Groups V and VI. By the bead-brush technique, polymerization happens in different periods of time as each acrylic resin increment is added, favoring heat dissipation and decreasing monomer vaporization.

Because the thickness of the acrylic resin is small in provisional crowns it is believed that surface porosity and roughness is given by the evaporation of the monomer during polymerization. Clinical observations suggest that, once immersed in water, monomer evaporation decreases resulting in less roughness and porosity. The same can be seen when acrylic resin polymerization occurs in the mouth, in contact with saliva. The observation of these variables alone is not enough to advocate certain technique, whether for making provisional crowns, or relining and repairs. Other physical properties of acrylic resins are also important such as surface hardness, wear, water sorption, flexional resistance and color stability, among others. Polishing also has a decisive effect on roughness and must be taken into account1,3,15. The assessment of these properties altogether may allow us to suggest a technique that best suits the needs of both the patient and the general dental practitioner.

CONCLUSIONS

There was a positive correlation between roughness and porosity of the acrylic resin used for temporary crowns. Specimens fabricated by direct techniques reached the highest roughness and porosity values, while those made by indirect and bead-brush techniques obtained the lowest values. Indirect (laboratory) techniques for making provisional crowns must be preferred over direct ones.

REFERENCES

1. Barbosa GKS, Zavanelli AC, Guilherme AS, Zavanelli RA. Effect of finishing and polishing techniques on the surface roughness of resin acrylic used on temporary restorations. Cienc Odontol Bras 2009;12(1):15-22. [ Links ]

2. Brecx M, Theilade J, Attström R. An ultrastructural quantitative study of the significance of microbial multiplication during early dental plaque growth. J Periodontal Res 1983;18(2):177-86. [ Links ]

3. Kuhar M, Funduk N. Effects of polishing techniques on the surface roughness of acrylic denture base resins. J Prosthet Dent 2005;93(1):76-85. [ Links ]

4. Lie T. Early dental plaque morphogenesis. A scanning electron microscope study using the hydroxyapatite splint model and a low-sucrose diet. J Periodontal Res 1977;12(2):73-89. [ Links ]

5. Lie T. Ultrastructural study of early dental plaque formation. J Periodontal Res 1978;13(5):391-409. [ Links ]

6. Lie T. Morphologic studies on dental plaque formation. Acta Odontol Scand 1979;37(2):73-85. [ Links ]

7. Lie T, Gusberti F. Replica study of plaque formation on human tooth surfaces. Acta Odontol Scand 1979;37(2):65-72. [ Links ]

8. McCracken WL. An evaluation of activated methyl metacrylate denture base materials. J Prosthet Dent 1952;2(1):68-83. [ Links ]

9. Morris IJ, Wade WG, Aldred MJ, Walker DM. The early bacterial colonization of acrylic palates in man. J Oral Rehabil 1987;14(1):13-21. [ Links ]

10. Mourouzis P, Koulaouzidou EA, Vassiliadis L, Helvatjoglu-Antoniades M. Effects of sonic scaling on the surface roughness of restorative materials. J Oral Sci 2009;51(4):607-14. [ Links ]

11. Newman HN. Diet, attrition, plaque and dental disease. Br Dent J 1974;136(12):491-7. [ Links ]

12. Nyvad B, Fejerskov O. Scanning electron microscopy of early microbial colonization of human enamel and root surfaces in vivo. Scand J Dent Res 1987;95(4):287-96. [ Links ]

13. Phillips RW. Skinner’s science of dental materials. 9 ed. Philadelphia: Saunders; 1991.

14. Quirynen P, Bollen CML. The influence of surface roughness and surface-free energy on supra- and subgingival plaque formation in man. A review of the literature. J Clin Periodontol 1995;22(1):1-14. [ Links ]

15. Sen D, Göller G, Işsever H. The effect of two polishing pastes on the surface roughness of bis-acryl composite and methacrylate-based resins. J Prosthet Dent 2002;88(5):527-32. [ Links ]

16. Shillingburg HT, Hobo S, Whitsett LD, Jacobi R, Brackett SE. Fundamentals of fixed prosthodontics. 3 ed. Chicago: Quintessence; 1997. [ Links ]

17. Yamauchi M, Yamamoto K, Wakabayashi M, Kawa-no J. In vitro adherence of microorganisms to denture base resin with different surfacetexture. Dent Mater J 1990;9(1):19-24. [ Links ]

Corresponding address:

Corresponding address:

José H. Rubo

School of Dentistry of Bauru, University of São Paulo

Department of Prosthodontics

Alameda Octavio Pinheiro Brisola, 9-75

CEP 17012-901 – Bauru/SP, Brazil

Phone: (55) 14 3235-8231

e-mail: jrubo@fob.usp.br

Received in: 28/2/11

Accepted in:16/5/11