Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RFO UPF

versão impressa ISSN 1413-4012

RFO UPF vol.15 no.3 Passo Fundo Set./Dez. 2010

Effect of different elastomers on cervical fit of full metal crowns

Efeito de diferentes elastômeros na adaptação cervical de coroas totais metálicas

Jefferson Ricardo PereiraI; Alessandro GavazzoniII; José Fernando Scarelli LopesIII; Accácio Lins do ValleIV; João Henrique Nogueira PintoIII

IProfessor, Departament of Prosthodontics, Dental School - University of South of Santa Catarina - Unisul, Tubarão, SC, Brazil

IIPos-graduated student, Departament of Prosthodontics, Hospital Rehabilitation of Craniofacial Anomalies - University of São Paulo, Bauru, SP, Brazil

IIIProfessor, Departament of Prosthodontics, Hospital Rehabilitation of Craniofacial anomalies - University of São Paulo, Bauru, SP, Brazil

IVProfessor, Departament of Prosthodontics, Bauru Dental School - University of São Paulo, Bauru, SP, Brazil

ABSTRACT

OBJECTIVE: The aim of this study was to evaluate the cervical fit of full metal crowns using four different elastomers.

METHODS: A stainless steel metallic die similar to a prepared first upper molar was obtained. Four different elastomeric impression materials were utilized: polysulfide (A), polyether (B), condensation silicone (C) and addition silicone (D). Forty molds were created, 10 for each group. It was obtained 40 gypsum abutments. After the end of this stage, it was performed complete metal crowns on all specimens. Crown displacement was measured through a comparative microscope, obtaining diametrically opposite points.

RESULTS: The results were the following: Group D (31.97 μm), Group B (49.57 μm), Group A (51.12 μm), Group C (61.12 μm). The analysis of variance (ANOVA) test and a Tukey test for multiple comparisons were used to analyze the results.

CONCLUSIONS: There were significant differences among all groups, except for Groups A and B. The major result of displacement was Group C. The best results were shown by Group D (p < 0.05).

Key words: Dental impression materials. Dental impression technique. Dental prosthesis.

RESUMO

OBJETIVO: O objetivo deste estudo foi avaliar o desajuste cervical de coroas metálicas utilizando quatro diferentes materiais elastoméricos.

MATERIAIS E MÉTODO: Foi confeccionado um troquel metálico de aço inoxidável semelhante a um primeiro molar superior preparado. Quatro diferentes materiais de moldagem elastoméricos foram utilizados: polissulfeto (A), poliéster (B), silicone de condensação (C) e silicone de adição (D). Quarenta moldes foram obtidos, sendo dez para cada grupo. Desses foram obtidos quarenta troqueis de gesso. Após o término desta fase, foram confeccionadas coroas totais metálicas em todas as amostras. O deslocamento da coroa foi medida com um microscópio comparador, obtendo-se pontos diametralmente opostos.

RESULTADOS: Foram os seguintes: Grupo D (31.97 μm), Grupo B (49.57 μm), Grupo A (51.12 μm), Grupo C (61.12 μm). A análise de variância (ANOVA) e o teste de Tukey para comparações múltiplas foram utilizados para análise dos resultados.

CONCLUSÕES: Houve diferenças significativas entre os grupos, exceto para os Grupos A e B. O maior resultado de deslocamento foi para o Grupo C, e os melhores resultados foram apresentados pelo Grupo D (p < 0,05).

Palavras-chave: Materiais para moldagem odontológica. Técnica de moldagem odontológica. Prótese dentária.

Introduction

The preparation of a fixed prosthesis is a very detailed sequence of procedures whose steps are completely interdependent. The technique of casting stands out as one of the most important clinical interventions for the success of the fixed prosthesis; it is the link between the laboratory and the clinical stage1.

The procedure of taking impressions has been known since antiquity. However, only since the 1950s, with the appearance of polysulfide, have the materials begun to be improve in an attempt to achieve "ideal" characteristics. At approximately the same time, around 1960, silicone was developed and work began on the marketing of polyether. Since then, the clinician has been facing a new era with regard to impression techniques, mainly due to the wide variety of materials and trademarks. Currently, the most commonly used materials in fixed prosthodontics are polyether, polysulfide, condensation silicone and addition silicone.

Addition silicone and polyether are the materials that have the best characteristics and dimensional stability, fidelity of copied details, elastic recovery, and lower values of deformation2. Polysulfide has advantages such as good working time, low cost and good resistance to tear, which is very important considering the impression is made with individual coping, where a small amount of material is used to reduce distortion and to resist tearing3,4. The disadvantages are unpleasant odor, ability to stain and impaired elastic memory3. Condensation silicone is a material widely used by professionals due to its ease of use and low cost. However, it has low resistance to tear than other elastomers and exaggerated distortion when stored for subsequent pouring2,5-7.

Therefore, the aim of this study was to provide greater knowledge of the physical characteristics of such materials so that they can, ideally, be used optimally in various situations of dental treatment. The hypothesis was that there was significant difference on cervical fit of full metal crowns in gypsum dies obtained with different elastomeric materials.

Materials and method

It was used a standard metal made of stainless steel with features of the upper first molar, which was impressioned with four different rubber-based materials: Group 1 - polysulfide (PermlasticTM; Kerr, West Collins Orange - CA, EUA), Group 2 - polyether (Impregum FTM; 3M, St. Paul - MM, EUA), Group 3 - condensation silicone (Optosil-XantoprenTM; 3M, Schurz - Straße - NEUSS, Germany) and Group 4 - addition silicone (AquasilTM; Dentsply, De-Trey-Straße - Konstanz, Germany). From this pattern, it was obtained 40 gypsum abutments divided in four groups, 10 for each material. After the end of this stage, it was performed the same procedure for the complete metal crowns on all specimens.

To create molding using polyether and polysulfide, it was made individual copings, which were made on the standard abutment in chemically activated acrylic resin (CAAR) (Clássico - Articles Dental S / A, Sao Paulo - SP, Brazil), with standard internal relief of 0.5 mm, and readapted with acrylic resin (Duralay, Reliance Dental Mfg Co Worth, Alsip - IL, EUA). Subsequently, It was done wax relief, with thickness of 3 mm, on the whole abutment3 an individual coping being made in individual CAAR trays (Clássico - Articles Dental S / A, Sao Paulo - SP, Brazil), not perforated.

For molding with addition and condensation silicone it was used individual perforated RAAQ trays (Clássico - Articles Dental S / A, Sao Paulo - SP, Brazil), made in a similar manner to that described previously. The technique of double mixing is the technique of choice for these two materials, and the relief from the heavy and light material was achieved by the interposition of a polyethylene film with 0.2 mm thickness.

The patterns obtained by the four groups were assessed and, if they were not satisfactory, would be discarded and a new procedure would be performed. The manipulation of both the material and the plaster casting followed the recommendations of the manufacturers. The molds of polyether, polysulfide and condensation silicone were poured, after the prey of these materials, with type IV plaster (DuroneTM; Dentsply, Petropolis - RJ, Brazil); thus reducing the occurrence of dimensional changes in the models obtained8. For the addition silicone mold, the pouring was performed after 1 hour of prey of the material to avoid the occurrence of pores in plaster abutments due to the release of H29,10. The conditions of temperature (23 ± 2 °C) and humidity (50 + / - 10%) were the same for all materials.

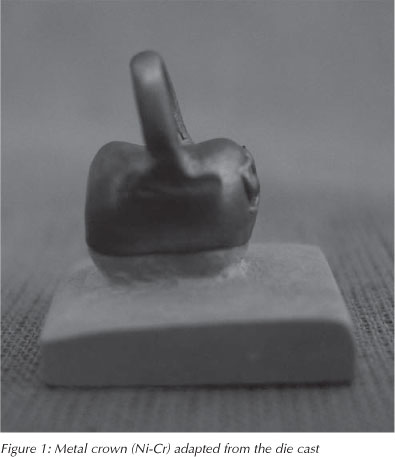

Forty metal crowns were obtained by the technique of lost wax. The wax patterns were sprued, invested (CristobaliteTM; Whip Mix Corp, Louisville, KY, USA), and cast using standard Ni-Cr alloy (Durabond, Sao Paulo, Brazil). After finishing and polishing, the crowns were seated on the standard model (Fig. 1) with a load of adjustment of 9 kg, maintained for 1 min11. After this time, the specimen was taken to the microscope optical comparator (MitutoyoTM; Mitutoyo Manufacturing Co., Tokyo - Tokyo, Japan) to perform measurements of cervical misfit in four diametrically opposite points, located on the vestibular, palatal, mesial and distal faces. There were three measurements for each point and the average was considered as cervical misfit.

Results

The analysis of variance (Anova) test and a Tukey test for multiple comparisons were used to analyze the results. In all cases it was adopted a significance level of 5% (p < 0.05). The addition silicone obtained lower mean misfit (31.97 μm), followed by the polyether (49.57 μm), polysulfide (51.12 μm) and the condensation silicone (61.12 μm). There were statistically significant differences between all groups, except between polysulfide (Group A) and polyether (Group B). The condensation silicone (Group C) displayed greater mismatch. The addition silicone (Group D) had a lower cervical misfit.

Discussion

Professionals achieve satisfactory outcomes, thorough knowledge of different techniques and impression materials, with respect to the type of tooth preparation (partial or total) or the cervical end level (supragingival or subgingival), aside from the need for technical skills to perform the procedure correctly.

The results of this study showed that the addition silicone performed superiorly to other materials (31.97 μm), probably due to its high dimensional stability and lower permanent deformation, a fact confirmed by Craig and Sun9. The material does not release sub products after its polymerization, as reported by Rubel6 (2007); it also has low polymerization contraction and good elastic recovery2,12.

The materials molded by individual copings (polyether and polysulfide) showed similar results, although polyether is more accurate and dimensionally stable than polysulfide13. This can be explained by the fact that the individual coping technique allows only a small amount of material to be used and thereby promotes a smaller dimensional change4,14. The similarity of results between these two groups is in agreement with results obtained by Boulton et al.15 (1996).

Condensation silicone presented the worst results with respect to cervical fit (61.12 μm), when compared to the other three materials. Rubel6 (2007) explained that the high degree of contraction is caused by the release of by-products (alcohol) during its prey reaction. This feature was confirmed by Johnson and Craig e Sun9 (1994) and Myers and Peyton16 (1959) who compared addition and condensation silicone, and indicated the former as the material of choice.

Although addition silicone performed superiorly to other materials it is necessary a waiting time of 1 hour to be poured to avoid bubbles caused by hydrogen released, the others could be poured immediately. Moreover the individual coping technique allows a small amount of material to be used and thereby promotes a smaller dimensional change when polyether and polysulfide are selected.4

It is interesting to note that even if introduction of a range of variables difficult to control, such as wax, coating, casting or other processes could also show differences in the cervical adaptation of total metal crowns of Ni-Cr using different types of elastomeric materials. Although there is a statistically significant difference between the addition silicone and polyether and polysulfide groups, the clinical use of any of these materials can be indicated, and it is a professional's responsibility to choose the material that has higher affinity, according to cost, work time and number of prepared teeth17,18.

Conclusions

Within the limits of this study, the following conclusions were drawn:

- There were statistically significant differences between all groups, except between polysulfide (Group A) and polyether (Group B).

- The condensation silicone (Group C) displayed greater mismatch.

- The addition silicone (Group D) had a lower cervical misfit.

References

1. Bull AW, Brinsden GI. Gingival tissue retraction for the elastic impression materials. Aust Dent J 1967; 12:310-3. [ Links ]

2. Faria ACL, Rodrigues RCS, Macedo AP, Mattos MGC, Ribeiro RF. Accuracy of stone casts obtained by different impression materials. Braz Oral Res 2008; 22(4):293-8. [ Links ]

3. Walters RA, Spurrier S. An effect of tray design and material retention on the linear dimensional changes in polysulfide impressions. J Prosthet Dent 1990; 63(3):277-81. [ Links ]

4. Millstein P, Maya A, Segura C. Determining the accuracy of stock and custom tray impression/casts. J Oral Rehabil 1998; 25(8):645-8. [ Links ]

5. Donovan TE, Chee WW. A review of contemporary impression materials and techniques. Dent Clin North Am 2004; 48(2):445-70. [ Links ]

6. Rubel BS. Impression materials: a comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am 2007; 51(3):629-42. [ Links ]

7. Johnson GH, Craig RG. Accuracy of addiction silicone as a function of technique. J Prosthet Dent 1986; 55:197-203. [ Links ]

8. Eames WB, Wallace SW, Suway NB, Rogers LB. Accuracy and dimensional stability of elastomeric impression materials. J Prosthet Dent 1979; 42:159-62. [ Links ]

9. Craig RG, Sun Z. Trends in elastomeric impression materials. Oper Dent 1994; 19: 138-45. [ Links ]

10. Nicholson JW, Medlock JW, Norling BK. Quantifying gas evolution from addition silicone elastomers. J Dent Res (Special Issue ) 1985; 64:243. [ Links ]

11. Grieve AR. A study of dental cements. Brit Dent J 1969; 127:405-10. [ Links ]

12. Araujo PA, Jorgensen KD. Effect of material bulk and undercuts on the accuracy of impression materials. J Prosthet Dent 1985; 54:11-2. [ Links ]

13. Ciesco JN, Malone WF, Sandrik JL, Mazur B. Comparison of elastomeric impression materials used in fixed prosthodontics. J Prosthet Dent 1981; 45:89-94. [ Links ]

14. Schenell RJ, Phillips RW. Dimensional stability of rubber-base impressions and certain other factors affecting accuracy. J Am Dent Assoc 1958; 57:39-48. [ Links ]

15. Boulton JL, Cage JP, Vincent PF, Basford KE. A laboratory study of dimensional changes for three elastomeric impression materials using custom and stock trays. Aust Dent J 1996; 41:398-404. [ Links ]

16. Myers GE, Peyton FA. Clinical and physical studies of the silicone rubber impression materials. J Prosthet Dent 1959; 9:315-24. [ Links ]

17. Lepers E. A method for more exact impressions of fixed partial dentures. Quintessence Int 1971; 1:39-56. [ Links ]

18. Livatidis GJ. Comparison of the new matrix system with traditional fixed prosthodontic impression procedures. J Prosthet Dent 1998; 79:200-7. [ Links ]

Correspondece to:

Correspondece to:

Jefferson Ricardo Pereira

Av. Rio Grande do Sul, 1901 / 303, Mar Grosso

88790000 Laguna - SC

Fones: (48) 3647 1571 Fax: (48) 3626 4088

Email: jeffripe@rocketmail.com

Recebido: 12.04.2010

Aceito: 13.09.2010