Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RFO UPF

versão impressa ISSN 1413-4012

RFO UPF vol.16 no.1 Passo Fundo Jan./Abr. 2011

Superficial roughness of composite resin submitted to different surface treatments – an in vitro study

Rugosidade superficial de resina composta submetida a diferentes tratamentos de superfície – estudo in vitro

Maristela Dutra-Corrêa*; João Maurício Ferraz da Silva**; Lia Alves Cunha**; Ângela Bolanho***; Clovis Pagani****

* Professora do Programa de Pós-Graduação; mestrado em Odontologia, Universidade Paulista, São Paulo, SP, Brasil.

** Doutor em Dentística, Departamento de Odontologia Restauradora, Faculdade de Odontologia de São José dos Campos, Universidade Estadual Paulista, São José dos Campos, SP, Brasil.

*** Aluna do curso de pós-doutorado em Bioquímica da Faculdade de Odontologia de Bauru da USP, Bauru, SP, Brasil.

**** Professor Adjunto, Departamento de Odontologia Restauradora, Faculdade de Odontologia de São José dos Campos, Universidade Estadual Paulista, São José dos Campos, SP, Brasil.

RESUMO

Introdução: O objetivo deste estudo foi avaliar a rugosidade superficial de uma resina composta submetida a diferentes tratamentos de superfície in vitro. Métodos: Foram confeccionados trinta corpos-de-prova com a resina composta compactável P60® (3M ESPE), com diâmetro de 3 mm e altura de 6 mm. Os corpos-de-prova foram armazenados em água destilada por sete dias a 37 ºC e divididos aleatoriamente em dois grupos. A rugosidade superficial das amostras foi determinada por um rugosímetro. A seguir, 15 amostras de cada material foram submetidas aos seguintes procedimentos de acabamento e polimento: Grupo I: brocas multilaminadas/ discos de lixa (Diamond Pro®, FGM); Grupo II: brocas multilaminadas/borrachas abrasivas (Enhance®/Pogo, Dentsply). O tempo de aplicação foi limitado em 20s para cada instrumento. Em seguida, foram realizados nova leitura e armazenamento. Depois os corpos-deprova foram polidos com discos de feltro e pasta diamantada (Diamond® Excel, FGM) por 20s e, na sequência, foi aplicado selante de superfície (Biscover®, Bisco). Após todos esses procedimentos, foi determinada a rugosidade final. A análise estatística foi realizada pelos testes RM Anova e Tukey (5%). Resultados e conclusões: Foram encontrados efeitos significativos tanto nos sistemas de polimento quanto no selante de superfície (presença ou ausência). O polimento com Diamond Pro® levou à maior rugosidade nas amostras (p < 0,05). Após a aplicação de Biscover®, os compósitos apresentaram- se mais lisos. Essa diferença foi significativa para o grupo polido com Diamond Pro® e não significativa para o grupo polido com Enhance/PoGo®. Concluiu-se que a aplicação de selante de superfície após polimento com discos de lixa ou com borrachas abrasivas resulta numa superfície com lisura superior à obtida apenas com os instrumentos de polimento .

Palavras-chave: Rugosidade superficial. Selante dentário. Polimento dentário.

ABSTRACT

The objective was to evaluate the superficial roughness of a composite resin submitted to different surface treatments, in vitro. Thirty specimens were made with P60TM packable composite resin (3M ESPE), 6 mm thick and 3 mm in diameter. The samples were stored in distilled water for 7 days at 37 ºC and randomly assigned to two test groups. The baseline superficial roughness was determined with a profilometer. Fifteen specimens of each material were subjected to the following finishing and polishing procedures: Group I: multi-fluted burs/ aluminum oxide disks (Diamond ProTM, FGM); Group II: multi-fluted burs/rubber tips (Enhance/PogoTM, Dentsply). Time was limited to 20s per instrument. Following these procedures, it was accomplished a new reading and storage. Then the samples were polished with felt disks with diamond paste (Diamond ExcelTM, FGM), for 20s, and a surface sealant was applied (Biscover, BISCO). After all these procedures, the final roughness was determined. Statistical analysis was performed with RM ANOVA and Tukey´s tests (5%). Significant effects were found with both the polishing systems and the sealant (presence or absence). The polishing with Diamond Pro caused the greatest roughness on all composites (p < 0.05). After the application of Biscover the composite surfaces were smoother. This difference was significant for the group polished with Diamond Pro and not significant for the group polished with EnhanceTM/Pogo. It was concluded that the application of a surface sealant following polishing with aluminum oxide disks or abrasive rubbers results in a surface with smoothness superior to that obtained with these polishing devices alone.

Keywords: Superficial roughness. Dental sealant. Dental polishing .

Introduction

The mechanical properties of dental composites depend to a large degree on the composition of the matrix and the concentration and particle size of the reinforcing filler1. The packable composite resins usually present more inorganic load than other composites, to promote better physical and mechanical properties. However, the physical properties of their matrix component can also affect the degree of polishability of these composites, making their surface less smooth than that of the hybrid composites2.

A smooth surface can be obtained through the polymerization of the composite resin against a mylar strip. However, diamond and carbide burs are necessary for contouring anatomically structures surfaces such as occlusal surfaces of posterior teeth. This procedure can compromise the performance of the composite, creating porosities or cracks in the tooth-restoration interface3-5.

Proper finishing and polishing of dental restorations are important aspects of clinical restorative procedures, independently of the type and location of the restoration, because they enhance both esthetics and longevity of restored teeth6-8. Residual surface roughness, associated with improper finishing and polishing, can result in a number of clinical problems, as excessive plaque accumulation9,10, gingival irritation, increased surface staining, poor or suboptimal esthetics of the restored teeth11, marginal leakage and secondary caries4,12. Besides, rough restorations in areas of occlusal contact might cause excessive wear of the antagonic enamel13.

Nowadays, the researchers have been seeking to develop new composite resins, with improved both physical and mechanical properties, as well as the ability to promote smooth surfaces. As there is an increasing search for aesthetic restorations, even in posterior teeth, it has also been encouraged the development of new finishing and polishing systems that could be able to promote smooth surfaces through a few and simple operative steps. On the other side, the diversity of technique options might lead to some doubts in the clinic routine14.

Therefore, the purpose of this in vitro study was to evaluate the surface roughness of a packable composite resin submitted to different surface treatments.

Materials and method

Thirty cylindrical specimens 6 mm thick and 3mm in diameter were prepared with the composite resin P60TM (3M ESPE, St Paul, MN, USA), using a metallic mold. The cavity of the mold was filled, with an amalgam plugger, in two increments of 1,5 mm, cured for 40s each one. The second increment was cured over a mylar strip. The polymerization was accomplished with the light-curing unit Curing Light XL 3000TM (3M Dental Products, St Paul, MN, USA), with a power density of 550 mW/cm2.

After removal of the mold, the samples were stored in distilled water at 37 °C for 7 days4,5 and then randomly assigned to one of the two test groups.

After storage, the baseline surface roughness (Ra) was determined with a profilometer (Perthen S8PTM, Mahr, Germany), expressed in μm. Three measurements were recorded for each specimen, and an overall Ra was determined for each sample.

Following, the samples were stored again in distilled water at 37 °C for 7 days.

After this time period, the finishing and polishing of the specimens were performed following two different protocols. Time was limited to 20s per instrument.

Group I: multi-fluted burs and aluminum oxide disks of different granulations were used (Diamond ProTM, FGM Produtos Odontológicos Ltda, Joinvile, SC, Brazil).

Group II: multi-fluted burs and abrasive rubbers were used (EnhanceTM/Pogo, Dentsply Indústria e Comércio, Petrópolis, RJ, Brazil).

After these procedures, a new reading was accomplished. Following, the samples were stored in the same way described previously.

At the end of the storage time, the two groups received identical treatment: all samples were polished with felt disks (Diamond FlexTM, FGM Produtos Odontológicos Ltda, Joinvile, SC, Brazil) and diamond paste (Diamond ExcelTM - extra-fine, FGM Produtos Odontológicos Ltda, Joinvile, SC, Brazil) for 20s. Following, a surface sealant (Biscover, Bisco Inc, Schaumburg, IL, USA) was applied and polymerized, according to the manufacturer's recommendations. After all these procedures, a new reading of the superficial roughness was accomplished.

Study design

The experimental variables in this study were polishing (aluminum oxide disks and abrasive rubbers) and application of surface sealant (absence or presence). To evaluate surface roughness change after treatment procedures, the change in Ra was calculated by subtracting the values obtained at baseline from the values obtained at the final reading.

Statistical analysis

The data that were subjected to statistical analysis using the software Minitab (Minitab, version 14.12, 2004).

The means and standard deviation was calculated for each specimen and statistical analysis was performed using repeated measures two-way Anova (RM Anova) (polishing and sealant), where the variable sealant was considered the repeated factor. All tests were carried out at 5% significance level.

Results

Statistical assumptions were evaluated before statistical analysis. The results indicated that the residuals were normally distributed and, by plotting against predicted values, the uniformity was checked, then none of the Anova assumptions were violated.

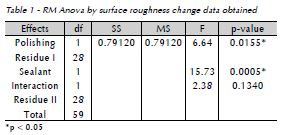

Analyzing the results of RM Anova it was revealed that the main effects polishing (p = 0.0155) and sealant (p = 0.0005) presented statistically significant difference. However, the effect interaction (p = 0.1340) was not significant statistically (Table 1). Therefore, the roughness change obtained with the sealant in the polishing with aluminum oxide disks does not differ from the change obtained with the sealant when the polishing was done with rubber tips.

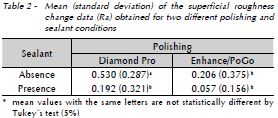

The superficial roughness data obtained with the study conditions are summarized in Table 2. Through analysis of the means, it was verified that there was higher roughness for the polishing with Diamond Pro (0.530) than there was for the polishing with Enhance/PoGo (0.206). When Enhance/ PoGo was followed by the application of surface sealant, roughness was slightly reduced, but the difference was not statistically significant. However, the application of sealant after polishing with Diamond Pro caused a statistically significant difference.

Discussion

Surface quality is an important parameter that influences the behavior of dental restorations in the oral environment in different ways. Finishing and polishing influence both the aesthetics and the longevity of the restorations7,8.

Several studies indicate that the Mylar strip produces the best surface on all the materials and among all of the of finishing and polishing methods8,13-15. However, trimming composite material is usually an inevitable procedure after the placement of direct composite restorations. This includes the gross removal of material and the contouring, finishing and polishing steps16.

Each composite resin requires specific finishing and polishing devices, depending on the size, hardness and amount of filler of the composite used17. After polishing with different systems, the surface characteristics, roughness and microhardness are dependent on the restorative material4.

Multi-fluted carbide and diamond burs are necessary for contouring anatomically structured and concave surfaces, such as the lingual surface of anterior teeth or occlusal surfaces of premolar and molar teeth14. As multi-fluted carbide burs are the optimal rotary contouring devices for posterior composite resins7, they were selected for finishing the specimens in this research.

Packable composite resins usually present more inorganic load than other composites, in order to increase their mechanical properties1. However, these materials present higher superficial roughness than the hybrid resins2,17-18. Thus, they might lead to more plaque accumulation, favoring secondary caries.

Regarding the polishing of the packable composite resin P60TM, the results of the present study showed that there was a statistically significant difference among the roughness obtained with aluminum oxide disks (Diamond ProTM) and abrasive rubbers (Enhance/PoGo). The greatest reduction in roughness was reached with the rubber instruments. This results agree with that of Marigo et al.13 (2001), which showed that EnhanceTM and Multi- stepTM systems promoted the best polishing for microfilled and hybrid composite resins. However, some authors indicated that polishing with Enhance led to rougher surfaces for all of four hybrid resins tested, compared to the MFS/MPSTM polishing system19.

Watanabe et al.20 (2005) showed that multiple steps polishing systems (Super-Snap and Enhance) were superior to one step systems (Compomaster and Silicone Points), regarding superficial roughness. Other authors also found similar results, being the smoothest surface obtained with the use of the complete sequence of the Sof-LexTM discs18,21.

Baseren8 (2004) found that Super-Snap aluminum oxide disks produced smoother surfaces than AstropolTM and AstrobrushTM silicon polishers, for all the tested materials. However, the author highlighted that the results would be valid clinically for readily accessible and flat surfaces i.e., not for all areas in the mouth. Therefore silicone polishers are necessary for posterior areas and for concave and convex surfaces.

It was observed in the present study that the application of the surface sealant Biscover reduced significantly the superficial roughness of the composite resin after both polishing with aluminum oxide disks and with rubber tips. These results are in agreement with other studies. Sarac et al.22 (2006) concluded that the use of Biscover after polishing disks (Sof-LexTM) or polishing wheels (Astropol) resulted in significantly lower Ra and less color change than the use of Astropol alone. Another surface sealant, Protect-it, also decreased the roughness values for the composite resins evaluated23. On the other hand, Takeuchi et al.24 (2003) did not find statistically significant differences among the P60TM resin specimens with and without application of the surface sealant Protect-it. Bolanho et al.15 (2003) also did not find improvement in the results of superficial roughness, after the sealant application, except for the resin Alert.

However, as described in the literature, the application of the surface sealant promotes other advantages for the composite resin restorations. The glaze promoted by Biscover appears to fill the structural microdefects and provide a more uniform and regular22.

It should also be highlighted that the interaction between polishing method and sealant was not statistically significant in this research, even though. The decrease in the surface roughness obtained with the condition Diamond Pro plus sealant does not differ from the decrease obtained with the condition Enhance/PoGo plus sealant.

Conclusion

With respect to Ra, P60TM composite resin specimens were significantly smoother when polishing was performed with abrasive rubbers than with aluminum oxide disks.

This study's data suggest that using a surface sealant following polishing with aluminum oxide disks or abrasive rubbers results in a surface with smoothness superior to that obtained with these polishing devices alone.

Referências

1. Hofmann N, Papsthart G, Hugo B, Klaiber B. Comparison of photo-activation versus chemical or dual-curing of resinbased luting cements regarding flexural strength, modulus and surface hardness. J Oral Rehabil 2001; 28:1022-8. [ Links ]

2. Cobb DS, MacGregor KM, Vargas MA, Denehy GE. The physical properties of packable and conventional posterior resin-based composites: a comparison. J Am Dent Assoc 2000; 131(11):1610-5.

3. Ferracane JL, Condon JR, Mitchen JC. Evaluation of subsurface defects created during the finishing of composites. J Dent Res 1992; 71(9):1628-32.

4. Yap AU, Lye KW, Sau CW. Surface characteristics of toothcolored restoratives polished utilizing different polishing systems. Oper Dent 1997; 22(6):260-5.

5. Warren DP, Colescott TD, Henson HA, Powers JM. Effects of four prophylaxis pastes on surface roughness of a composite, a hybrid ionomer, and a compomer restorative material. J Esthet Restor Dent 2002; 14(4):245-51.

6. Small BW. Direct posterior composite restorations. Gen Dent 1998; 46(1):26-32.

7. Jefferies SR. The art and science of abrasive finishing and polishing in restorative dentistry. Dent Clin North Am 1998; 42(4):613-27.

8. Baseren M. Surface roughness of nanofill and nanohybrid composite resin and ormocer-based tooth-colored restorative materials after several finishing and polishing procedures. J Biomater Appl 2004; 19(2):121-34.

9. Weitman RT, Eames WB. Plaque accumulation on composite surfaces after various finishing procedures. J Am Dent Assoc 1975; 91(1):101-6.

10. Kawai K, Urano M. Adherence of plaque components to different restorative materials. Oper Dent 2001; 26(4):396- 400.

11. Standford WB, Fan PL, Wozniak WT, Standford JW. Effects of finishing on color and gloss of composites with different fillers. J Am Dent Assoc 1985; 110(2):211-3.

12. Yap AU, Sau CW, Lye KW. Effects of finishing/polishing time on surface characteristics of tooth-colored restoratives. J Oral Rehabil 1998; 25(6):456-61.

13. Marigo L, Rizzi M, La Torre G, Rumi G. 3-D surface profile analysis: different finishing methods for resin composites. Oper Dent 2001; 26(6):562-8.

14. Ozgunaltay G, Yazici AR, Gorucu J. Effect of finishing and polishing procedures on the surface roughness of new toothcolored restoratives. J Oral Rehabil 2003; 30(2):218-24.

15. Bolanho A, Anauate-Netto C, Youssef MN, Do Carmo ARP, Mandelli A. Estudo in vitro da rugosidade superficial de resinas para dentes posteriores submetidas a diversos tratamentos de superfície. JBD – J Bras Dentística & Estética 2003; 2(5):51-7.

16. Jung M. Surface roughness and cutting efficiency of composite finishing instruments. Oper Dent 1997; 22(3):98-104.

17. Reis AF, Giannini M, Lovadino JR, Ambrosano GM. Effects of various finishing systems on the surface roughness and staining susceptibility of packable composite resins. Dental Mater 2003; 19(1):12-8.

18. Barbosa SH, Zanata RL, Navarro MF, Nunes OB. Effect of different finishing and polishing techniques on the surface roughness of microfilled, hybrid and packable composite resins. Braz Dent J 2005;6(1):39-44.

19. Kaplan BA, Goldstein GR, Vijayaraghavan TV, Nelson IK. The effect of three polishing systems on the surface roughness of four hybrid composites: a profilometric and scanning electron microscopy study. J Prosthet Dent 1996; 76(1):34-8.

20. Watanabe T, Miyazaki M, Takamizawa T, Kurokawa H, Rikuta A, Ando S. Influence of polishing duration on surface roughness of resin composites. J Oral Science 2005; 47(1):21-5.

21. Eide R, Tveit AB. Finishing and polishing of composites. Acta Odontol Scand 1988; 46:307–12.

22. Sarac D, Sarac YS, Kulunk S, Ural C, Kulunk T. The effect of polishing techniques on the surface roughness and color change of composite resins. J Prosthet Dent 2006; 96(1):33- 40.

23. Dos Santos PH, Consani S, Correr Sobrinho L, Coelho Sinhoreti MA. Effect of surface penetrating sealant on roughness of posterior composite resins. Am J Dent 2003; 16(3):197-201.

24. Takeuchi CY, Orbegoso Flores VH, Palma Dibb RG, Panzeri H, Lara EH, Dinelli W. Assessing the surface roughness of a posterior resin composite: effect of surface sealing. Oper Dent 2003; 28(3):281-6.

Endereço para correspondência:

Endereço para correspondência:

Lia Alves Cunha

Rua Paulo Edson Blair, 65/73B, Jd. Apolo II

12243-100 São José dos Campos - SP

e-mail: liaalves@hotmail.com

Recebido: 14.01.2010

Aceito: 13.10.2010