Services on Demand

Article

Related links

Share

Brazilian Journal of Oral Sciences

On-line version ISSN 1677-3225

Braz. J. Oral Sci. vol.10 n.2 Piracicaba Apr./Jun. 2011

ORIGINAL ARTICLE

Influence of ceramic primers on microshear bond strength between resin cements and zirconia-based ceramic

Valéria Bisinoto GottiI; Saturnino Calabrez FilhoII; Marcos Massao ShimanoIII; Gilberto Antônio BorgesIII; Luciano de Souza GonçalvesIII

I DDS, Graduate Student, Dental School, University of Uberaba, Brazil

IIDDS, MS, PhD, Professor, Restorative Dentistry Division, Dental School, University of Uberaba, Brazil

IIIDDS, MS, PhD, Professor, Biomaterials Division, Dental School, University of Uberaba, Brazil

ABSTRACT

Aim: This study evaluated the effect of a coupling agent ceramic primer (CP) on the microshear bond strength (ìsbs) between luting cements and zirconia-based ceramic. Methods: Zirconia discs (Cercon) were made and finished with silicon carbide paper and submitted to air abrasion using 50 μm aluminum oxide particles (Al2O3) under 4 bar pressure. Zirconia disks were randomly assigned to four groups (n=10): (G1) ResiCem luting cement + Porcelain Primer, (G2) ResiCem luting cement only, (G3) Clearfil Esthetic Cement + Clearfil Ceramic Primer and (G4) Clearfil Esthetic Cement only. The luting cements were prepared according to manufacturers' recommendations and inserted in an elastomeric mold positioned onto a zirconia disc. Each specimen was photoactivated by 20 s. The specimens were stored at 100% relative humidity and 37ºC for 24 h. The ìsbs test was performed using universal testing machine at a crosshead speed of 0.5 mm/min. An optical microscope was used to analyze the failure modes and illustrative images were captured with a scanning electron microscope. The ìsbs data were analyzed by two-way ANOVA (p<0.05). Results: No significant difference was found among the four groups G1 (17.4±6.8), G2 (17.1±5.5), G3 (15.6±5.5) and G4 (14.2±3.5), all of which showed 100% of adhesive failures. Conclusions: CP showed no increase in the ìsbs between zirconia-based ceramic and resin luting cements.

Keywords: zirconia, dual luting cement, bond strength.

Introduction

Zirconia-based ceramics present optimal mechanical properties, which are important for the long-term performance of these restorative materials1-3. The clinical success of all-ceramic restorations is dependent on the cementation process. Zirconia restorations can be cemented to the tooth with non-adhesive cements. However, the choice of a resin-cement agent would be justified due to the bond to the dental structure, with higher retention and better marginal adaptation4-6.

As there is no silica in its composition and it lacks a vitreous phase, conventional hydrofluoric acid etching and silanization procedures are incapable of modifying the zirconia surface4-6. Previous studies have recommended the use of airborne particle abrasion or silica coating for improving the bond strength to zirconia10-11. However, controversial results have been found12-15 with regard to the efficacy of these alternative treatment procedures. It has been shown that airborne particle abrasion alone does not provide adequate bond strength to zirconia-based ceramics because it promotes only mechanical retention on the surface16. Silica coating combined with silanization provides a chemical interaction with the resin luting cement and appears to be a more appropriate treatment17-18. However this treatment is expensive for the prosthetic laboratories and dentist.

Different resin luting cements with various blends of monomers have been developed to improve these materials and their chemical affinity with the ceramic surface. Higher chemical affinity would be attained with the use of resin cements containing phosphate monomers, such as 10- methacryloyloxydecyl dihydrogen phosphate (MDP), promoting higher bond strength4, or by using additional bond agents, called primers19-20, which also have these monomers in their composition. Nevertheless, another study has shown that the use of the primers without airborne particle abrasion promoted a non-durable bond to zirconia21. Therefore, the combination of airborne particle abrasion with primers requires further investigation.

According to previous studies4,20-21, the association of resin luting cements with primers promoted a better interaction with the ceramic surface due to the increase in cement wetting. This wetting favors the adhesion process and improves the chemical interaction between resin cement and the zirconia surface. These ceramic primers usually contain silane and a functional phosphated monomer. Clearfil Esthetic Cement (Kuraray) is composed of the functional monomer 10-MDP, 3-methacryloxypropyltrimetoxisilano (3- MPS) as silane and ethanol. Conventional silane is not effective on zirconia due to the absence of silica in its composition10,13,19. However, when a silane primer (3-MPS) reacts with 10-MDP, the interaction of the primer with the substrate and resin cement is promoted, forming cross links with the OH groups from ceramic and cement methacrylates. This reaction can be induced and sustained by the acidity of the ceramic treated with the coupling solution4. Primers containing other phosphate monomers, such as 6-MHPA (6- methacryloyloxyhexyl phosphonoacetate)9 and MTU-6 (6- methacryloyloxyhexyl 2-thiouracil-5-carboxylate)22 have been evaluated with less favorable results when compared with 10-MDP.

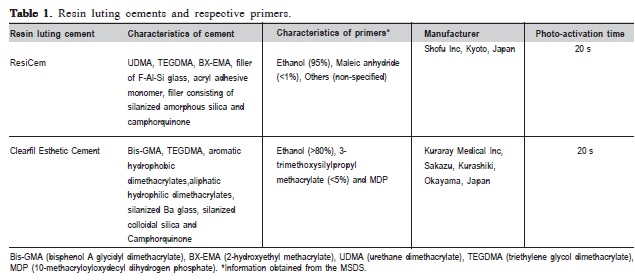

Addition of multifunctional methacrylate acids directly to cements that do not have primers, called self-adhesive cements, can also promote this higher interaction between the material and substrate4-23. However, ResiCem's manufacturer, Shofu Inc., does not disclose the full composition of the primer, omitting some components. In addition, no phosphate monomer is specified in the cement or primer formulations stated in the Material Safety Data Sheet (MSDS) (Table 1).

Therefore, the aim of this study was to investigate the effect of primers on the bond strength between resin luting cements and zirconia-based ceramic. The failure mode analysis was also examined after the test. The hypothesis tested in this study was that the application of a ceramic primer on airborne particle abraded zirconia surfaces increases the bond strength of resin cements.

Material and methods

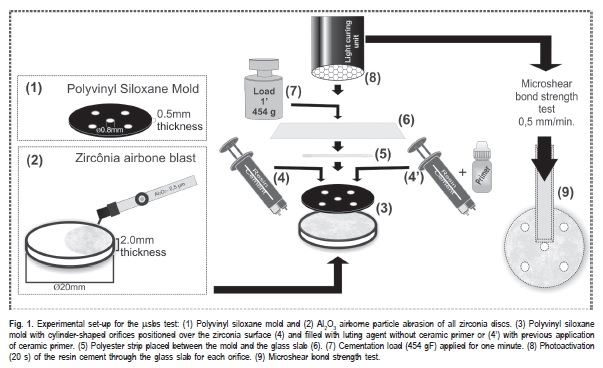

The materials used in this study are presented in Table 1. Forty zirconia discs (20 mm in diameter and 2 mm thick) were made from pressed blocks (Cercon, DeguDent GmbH, Hanau/Wofgang, Germany). After sintering, the finishing and polishing procedures were performed with 320-, 400-, 600- and 1200-grit silicon carbide papers.

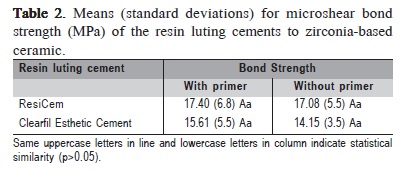

After the trimming, the zirconia discs were submitted to airborne particle abrasion with 50 μm (Al2O3), performed perpendicularly to the ceramic surface for 10 s at a distance of 10 mm. After airborne particle abrasion, the zirconia discs were cleaned in an ultrasonic bath (Odontobras Ind. & Com. de Equipamentos Médico Odontológicos LTDA., Ribeirão Preto, SP, Brazil) immersed in ethanol for 5 min, immersed in distilled water for 5 min and dried with oil-free air blast. Pretreated zirconia discs were then divided into four groups (n=10) according to the bond procedure and the resin luting cement (Table 2).

Adhesion procedures were performed at room temperature and controlled humidity (23 ± 2ºC and 50 ± 5%, respectively) according to the ISO/TS 11405/2003 Standard. Customized 0.5-mm-thick polyvinyl siloxane molds (Vigodent S.A. Indústria e Comércio, Rio de Janeiro, RJ, Brazil) with five cylinder-shaped orifices (0.8 mm in diameter) were placed on the ceramic discs to allow delimitation of the bond area. Resin luting cements were prepared according to the manufacturers' instructions and inserted in the mold orifice with a #5 explorer (Duflex - SS White do Brasil, Rio de Janeiro, RJ, Brazil). Excess cement was removed with a #24 spatula (Duflex). The orifices were filled with each of the resin luting cements, and a transparent polyester strip was placed over the filled orifices. Before polymerization, a constant and uniform 0.454 kgF load was applied for 1 min, using a custom-made device. Samples were photoactivated in continuous mode with a LED Radii Cal (SDI. Victoria®, Australia) appliance with 1,400 mW/cm2 irradiance, as verified with a power meter (Ophir Optronics Ltda.®, Jerusalém, Israel) for 20 s for each orifice individually. After activation, samples were stored at 37 ºC and 100% relative humidity for 24 h, protected from light.

The μsbs test was performed in a universal testing machine (EMIC DL 3000®; (EMIC, São José dos Pinhais, PR, Brazil), using a knife-edged blade at a crosshead speed of 0.5 mm/min until fracture. The μsbs of each zirconia disc was obtained by calculating the mean value of five repetitions on the surface of each disc, as shown in Figure 1. This procedure was performed to submit a larger area of the disc to bond strength test, increasing the reliability of the values of each specimen. The μsbs data were submitted to two-way ANOVA (p=0.05).

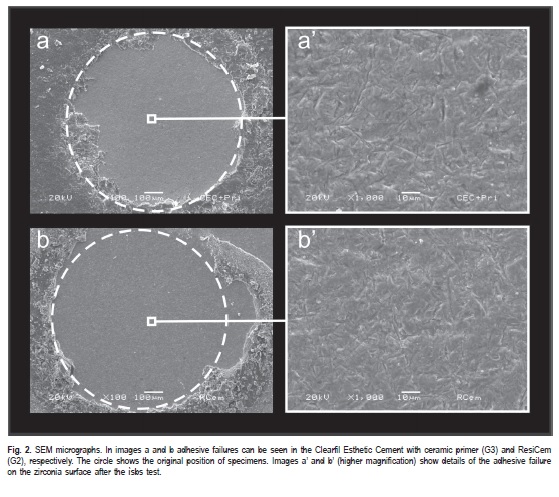

Failure mode analysis was performed with a stereomicroscope at 40x magnification and classified as: cohesive in cement (C), adhesive (A) and mixed (M). In addition, representative fractured specimens were sputter-coated with gold and examined with a scanning electron microscope (JSM5600LV; JEOL Inc., Peabody, MA, USA).

Results

The μsbs test results are shown in Table 2. Two-way ANOVA showed that no significant differences in bond strength were detected. The studied factors revealed no statistically significant difference among the resin luting cements used in this study (p = 0.179). The same occurred with regard to the ceramic surface treatments with primer (p = 0.609) and the interaction between the factors (p = 0.742). Failure mode analysis showed 100% of adhesive failures, SEM micrographs of fractured specimens are shown in Figure 2.

Discussion

The influence of different surface treatments and ceramic primers on the bond strength of zirconia-based ceramics has been extensively investigated. The majority of studies have demonstrated that chemical or mechanical modification was shown to positively influence bond strength to resin luting cements12-15,24. However the increase in bond strength was not always achieved, with contradictory results being shown2,6,12-15,200,25. In the present study, no statistically significant difference was found in the bond strength between the resin luting cements and zirconia discs, irrespective of the bond agent applied to the ceramic (Table 2). The similarity between the bond strength values of the two agents, ResiCem (Shofu) and Clearfil Esthetic Cement (Kuraray), probably occurred because of the absence of phosphate monomers in their compositions as reported in the manufacturer's MSDS of the respective products. Both resin cements have only inorganic particles in the organic matrix of methacrylates, as shown in Table 1. It is known that monomers, such as MDP or 4-methacryloxyethyl trimellitic anhydride (4-META), present chemical bond to metal oxides13-26. Previous studies have shown that the chemical interaction of these functional monomers can improve the bond strength of crystalline ceramics such as zirconia and alumina, as well as the long-term bond stability, when compared with conventional methacrylates26-27.

A previous study reported that the functional monomers are able to form chemical bonds with the metal oxides of zirconia, secondary bonds such as van der Waals, or hydrogen bonds at the ceramic-resin interface, increasing the surface wettability21. This increase in bond strength is more evident when functional monomers are used in combination with mechanical retention by means of surface pretreatment, such as airborne particle abrasion or silica coating4.

In the present study, the application of primer to ceramic had no influence on the μsbs of the cementation agents to the zirconia discs treated with 50 μm airborne particle abrasion. Nevertheless, the majority of studies have shown better bond strength results when associated with primer application4,12,20. However, previous studies have shown that even in the presence of functional monomers, it is important to use different surface treatments to increase resin cement bond strength to zirconia-based ceramics4,9. The combination factors, such as the use of resin cements containing adhesive phosphate monomers, airborne particle abrasion pressure and primers containing MDP, could promote a durable long-term bond to zirconia20-22,28. The use of primers without alumina airborne particle abrasion resulted in no long-term interlocking with the zirconia surface20-21. In a previous study, when airborne particle abrasion was combined with primers containing MDP, higher tensile bond strength values allied to low percentages of adhesive failures were observed21. Therefore, the absence of phosphate monomers in the composition of the cement and primer of ResiCem may have not affected the bond strength. Perhaps, there should be phosphate monomer in the resin cement and primer. The combined action of the two materials would increase the presence of phosphate-radicals, and could lead to a better bond between the zirconia and resin cement. Therefore, in the present study, the effect of primers, irrespective of the presence of MDP probably had less influence than retentions created by the Al2O3 airborne particle abrasion, resulting in similar μsbs values for both groups.

The failure mode analysis also indicated that the bond between the resin cement and zirconia surface was not improved by the action of the primers. All specimens showed adhesive failures, and no increase in μsbs values was found. The appearance of resin cement debris (e.g. mixed failure) would indicate a better bond of cement to parts of the zirconia surface, forcing the stress into the cement bulk, inducing points of cohesive failure. Figure 2 shows the adhesive failure mode for Clearfil Esthetic Cement with ceramic primer (a and a') and ResiCem without the use of primer (b and b'). At higher magnification, details of the adhesive failure show the zirconia surface with grooves formed by the Al2O3 airborne particle abrasion without residual cement in the bond area (dotted line).

Some authors have pointed out that the use of primer for ceramic, especially those that contain MDP, promoted a more resistant bond in the short term. Silica coating associated with application of the primer would be the treatment of choice to increase bond stability. However, degradation of this bond was found even in the presence of the functional monomer with a long-chain carbonyl contained in Clearfil Ceramic Primer4.

The bond to zirconia remains an insightful and challenging procedure to the clinician. Therefore, with the increase in clinical use of ceramics in Dentistry, more evidence related to the adhesive cementation of zirconiabased ceramic restorations is necessary to establish the most reliable technique, since the zirconia surface cannot be conditioned by conventional pretreatment methods. The present study showed that primers do not necessarily improve the bond strength to zirconia. Therefore, further studies are required to develop more efficient primers and cements, or more reliable alternative methods to improve the bond strength to zirconia-based ceramics. The aging process of resin cements must be analyzed to establish a more durable and reliable chemical and mechanical bond strength on the cementation process.

Based on the limitations of this study it may be concluded that: no difference in μsbs was found between the resin luting cements used in this study; application of the ceramic primer to the ceramic did not improve the bond strength of the resin cements to zirconia-based ceramic surfaces.

References

1. D'Amario M, Campidoglio M, Morresi AL, Luciani L, Marchetti E, Baldi M. Effect of thermocycling on the bond strength between dual-cured resin cements and zirconium-oxide ceramics. J Oral Sci. 2010; 52: 425-30. [ Links ]

2. de Souza GM, Silva NR, Paulillo LA, De Goes MF, Rekow ED, Thompson VP. Bond strength to high-crystalline content zirconia after different surface treatments. J Biomed Mater Res B Appl Biomater. 2010; 93: 318-23.

3. Phark JH, Duarte S Jr, Blatz M, Sadan A. An in vitro evaluation of the long-term resin bond to a new densely sintered high-purity zirconiumoxide ceramic surface. J Prosthet Dent. 2009; 101: 29-38.

4. de Oyague RC, Monticelli F, Toledano M, Osorio E, Ferrari M, Osorio R. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dent Mater. 2009; 25: 172-9.

5. Ural C, Kulunk T, Kulunk S, Kurt M. The effect of laser treatment on bonding between zirconia ceramic surface and resin cement. Acta Odontol Scand. 2011; 68: 354-9.

6. Kitayama S, Nikaido T, Takahashi R, Zhu L, Ikeda M, Foxton RM, et al. Effect of primer treatment on bonding of resin cements to zirconia ceramic. Dent Mater. 2010; 26: 426-32.

7. Foxton RM, Cavalcanti AN, Nakajima M, Pilecki P, Sherriff M, Melo L, et al. Durability of resin cement bond to aluminium oxide and zirconia ceramics after air abrasion and laser treatment. J Prosthodont. 2011; 20: 84-92.

8. Ozcan M, Cura C, Valandro LF. Early bond strength of two resin cements to Y-TZP ceramic using MPS or MPS/4-META silanes. Odontology. 2011; 99: 62-7.

9. Takeuchi K, Fujishima A, Manabe A, Kuriyama S, Hotta Y, Tamaki Y, et al. Combination treatment of tribochemical treatment and phosphoric acid ester monomer of zirconia ceramics enhances the bonding durability of resin-based luting cements. Dent Mater J. 2010; 29: 316-23.

10. Cavalcanti AN, Foxton RM, Watson TF, Oliveira MT, Giannini M, Marchi GM. Bond strength of resin cements to a zirconia ceramic with different surface treatments. Oper Dent. 2009; 34: 280-7. 11. Kumbuloglu O, Lassila LV, User A, Vallittu PK. Bonding of resin composite luting cements to zirconium oxide by two air-particle abrasion methods. Oper Dent. 2006; 31: 248-55.

12. Atsu SS, Kilicarslan MA, Kucukesmen HC, Aka PS. Effect of zirconiumoxide ceramic surface treatments on the bond strength to adhesive resin. J Prosthet Dent. 2006; 95: 430-6.

13. Blatz MB, Phark JH, Ozer F, Mante FK, Saleh N, Bergler M, et al. In vitro comparative bond strength of contemporary self-adhesive resin cements to zirconium oxide ceramic with and without air-particle abrasion. Clin Oral Investig. 2010; 14: 187-92.

14. Valandro LF, Ozcan M, Bottino MC, Bottino MA, Scotti R, Bona AD. Bond strength of a resin cement to high-alumina and zirconia-reinforced ceramics: the effect of surface conditioning. J Adhes Dent. 2006; 8: 175-81.

15. Wolfart M, Lehmann F, Wolfart S, Kern M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent Mater. 2007; 23: 45-50.

16. Borges GA, Sophr AM, de Goes MF, Sobrinho LC, Chan DC. Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J Prosthet Dent. 2003; 89: 479-88.

17. Kim BK, Bae HE, Shim JS, Lee KW. The influence of ceramic surface treatments on the tensile bond strength of composite resin to all-ceramic coping materials. J Prosthet Dent. 2005; 94: 357-62.

18. Senyilmaz DP, Palin WM, Shortall AC, Burke FJ. The effect of surface preparation and luting agent on bond strength to a zirconium-based ceramic. Oper Dent. 2007; 32: 623-30.

19. Blatz MB, Chiche G, Holst S, Sadan A. Influence of surface treatment and simulated aging on bond strengths of luting agents to zirconia. Quintessence Int. 2007; 38: 745-53.

20. Kern M, Barloi A, Yang B. Surface conditioning influences zirconia ceramic bonding. J Dent Res. 2009; 88: 817-22.

21. Yang B, Barloi A, Kern M. Influence of air-abrasion on zirconia ceramic bonding using an adhesive composite resin. Dent Mater. 2010; 26: 44-50.

22. Yun JY, Ha SR, Lee JB, Kim SH. Effect of sandblasting and various metal primers on the shear bond strength of resin cement to Y-TZP ceramic. Dent Mater. 2010; 26: 650-8.

23. Miragaya L, Maia LC, Sabrosa CE, De Goes MF, Da Silva EM. Evaluation of Self-adhesive Resin Cement Bond Strength to Yttria-stabilized Zirconia Ceramic (Y-TZP) Using Four Surface Treatments. J Adhes Dent. 2010 Nov 8. doi: 10.3290/j.jad.a19820.

24. Menezes FCH, Borges GA, Valentino TA, Oliveira MAHM, Turssi CP, Correr-sobrinho L. Effect of surface treatment and storage on the bond strength of different ceramic systems. Braz J Oral Sci. 2009; 8: 119-23.

25. Della Bona A, Borba M, Benetti P, Cecchetti D. Effect of surface treatments on the bond strength of a zirconia-reinforced ceramic to composite resin. Braz Oral Res. 2007; 21: 10-5.

26. Leung Y, Morris MD. Characterization of the chemical interactions betwen 4- MET and enamel by Raman spectroscopy. Dent Mater. 1995; 11: 191-5.

27. Blatz MB, Sadan A, Martin J, Lang B. In vitro evaluation of shear bond strengths of resin to densely-sintered high-purity zirconium-oxide ceramic after long-term storage and thermal cycling. J Prosthet Dent. 2004; 91: 356-62.

28. Mirmohammadi H, Aboushelib MN, Salameh Z, Feilzer AJ, Kleverlaan CJ. Innovations in bonding to zirconia based ceramics: Part III. Phosphate monomer resin cements. Dent Mater. 2010; 26: 786-92.

Correspondence:

Correspondence:

Cristiane Miranda Franca Av. Conselheiro Rodrigues Alves, 948 apto 93 Vila Mariana, São Paulo, SP, Brazil CEP: 04014-002

E-mail: cristiane321@gmail.com

Received for publication: November 23, 2010

Accepted: May 18, 2011