Serviços Personalizados

Artigo

Links relacionados

Compartilhar

Brazilian Journal of Oral Sciences

versão On-line ISSN 1677-3225

Braz. J. Oral Sci. vol.11 no.4 Piracicaba Out./Dez. 2012

ORIGINAL ARTICLE

Influence of different mould materials on the degree of conversion of dental composite resins

Roberto Belloti CornelioI; MSc Hilde Molvig KopperudII; Johan HaasumIII; Ulf Wiel GeddeIV; Ulf ÖrtengrenV

IDDS, Department of Dentistry, Faculty of Health Science, University of Tromsø, Tromsø, Norway

IINordic Institute of Dental Materials, Oslo, Norway

IIIMSc, Fibre and Polymer Technology, School of Chemical Science and Engineering, Royal Institute of Technology, Stockholm, Sweden

IVProfessor, Fibre and Polymer Technology, School of Chemical Science and Engineering, Royal Institute of Technology, Stockholm, Sweden

VProfessor, Department of Dentistry, Faculty of Health Science, University of Tromsø, Tromsø, Norway

ABSTRACT

AIM: In this study, the degree of conversion (DC) was analyzed on the surfaces of dental composite resins cured in different mould materials with different irradiation times.

METHODS: Samples of three composite resins (Grandio®, Grandio Flow® [thickness = 2 mm; 4 mm; Ø = 5 mm] irradiated for 10 s, 20 s and 40 s and an experimental composite (EXPM) [thickness = 6 mm;Ø = 5 mm] irradiated for 40 s) were cured in moulds made of polytetrafluorethylene (PTFE), highdensity polyethylene (HDPE) and stainless steel (SS). The DC was analyzed by FT-Raman spectroscopy.

RESULTS: The DC was significantly lower for the 2-mm-thick samples of Grandio® cured with 20 s in the SS mould than in the PTFE mould. The same trend was found for the 4-mmthick samples of Grandio Flow® cured with 40 s. The main difference of the DC between Grandio® and Grandio Flow® occurred when 10 s irradiation was used, independently of the mould material and thickness of the samples. The analysis of the DC on the sites around the samples of EXPM showed no significant difference from those at the bottom when cured in each mould material with 40 s irradiation.

CONCLUSIONS: The DC was not affected by the mould material, instead, the resin formulation and the irradiation times were the main factors affecting the degree of conversion.

Keywords: mould material, dental composite resin, degree of conversion, Raman spectroscopy.

Introduction

For composite resin-based materials (CRM) used in dentistry, the reaction of the carbon-carbon double bonds (C=C) at the functional methacrylate groups of the monomers is important for the mechanical and physical properties of the resultant polymer. It is already known that not all double bonds react during the photopolymerization process1. Unreacted monomers and/or functional groups within the polymer can act as plasticizers and, therefore, have a negative impact on the mechanical properties1-5. Factors including type of monomers used and their viscosity6, the amount and type of filler particles7, the amount and type of initiators8-9, the curing device and the irradiation time10-11 have been found influencing the DC.

The effectiveness of the photopolymerization process can be measured by the DC (i.e. percentage of the reacted aliphatic carbon-carbon double bonds) and has been directly correlated with mechanical properties (e.g. hardness and shrinkage) of the composite resin-based materials6,12-17. Analyses of the DC have been performed using Fourier transformed (FT)-Raman spectroscopy, an effective quantitative method to analyze the reacted functional groups in the material18-21.

When testing composite resin-based materials in vitro, however, the results of the degree of conversion can be incorrectly estimated if different mould materials affect the DC, for instance, by the influence of entrapped oxygen into the mould material22-24. Therefore, in order to eliminate the risk of using a mould material that could bias the results achieved, further information about the influence of different mould materials on the DC of composite resin-based materials is needed.

The moulds used for preparing composite resin-based materials are often made of stainless steel (SS) as this mould material is used in the ISO-standard for dental composites25. However, the use of SS mould may need the addition of a lubricant agent (e.g. 3% wax in hexane) on the inner area of the mould in order to prevent the sample from being stuck inside the mould. The presence of lubricant may affect the degree of conversion in the final product. Moulds made of high-density polyethylene (HDPE) and polytetrafluorethylene (PTFE) have also been used for testing both commercial and experimental composites26. In addition, since degree of conversion is affected by the type of the monomers within the mixtures6, an investigation on the effectiveness of the DC of different CRM cured in different moulds seem also needed, due to the variety of monomer mixtures existing in the market. Therefore, the hypothesis of the present study was that plastic mould materials (PTFE and HDPE) would give a lower DC on the samples' surfaces directly in contact with the mould walls compared with the SS mould. The aim of the present investigation was to analyze the DC on the surfaces of samples with different thickness of two commercial composites and an experimental composite after being light-cured in 3 different mould materials with different irradiation times.

Material and methods

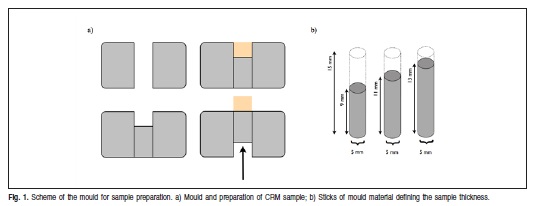

Mould materials

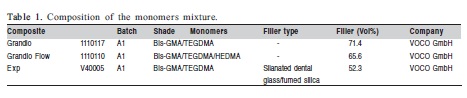

The mould materials investigated were PTFE, HDPE, and SS. The moulds were produced at the technical laboratory of the Royal Institute of Technology in Stockholm, Sweden. A 15-mm-thick block of each material was perforated through with a circular hole of 5 ± 0.1 mm diameter (Figure 1a). Three sticks, 9, 11 and 13 mm long, made of the same material as each mould, were produced to fit inside the perforation. The free space left inside the moulds was used to make the CRM samples (Figure 1b). The moulds were cleaned before the preparation of the samples with ethanol (96%) using Quick stick (Aplicator Tips; Dentsply, Detrey, GmbH, Konstanz) and dried before insertion of the CRM. A PTFE-Fat based lubricant (Presto Tech; Motip Dupli GmbH, Hassmersheim, Germany) was used on the inner area of the SS mould for the samples made of the experimental composites.

Samples

The composition of the 3 dental composites tested are presented in Table 1. The two commercial composites, Grandio® and Grandio Flow® (VOCO GmbH, Cuxhaven, Germany) were used to investigate the influence of the mould material on the DC under different irradiation times and thicknesses. The samples (thickness = 2 mm, 4mm; Ø = 5 mm) were divided in 36 groups (n=5), total of 180, according to the composite resin system, type of mould material, thickness of the samples and irradiation times. In a room temperature 23 ± 1oC, the composite was placed as a bulk in the hole with a slightly excess. A polyethylene terephthalate (PET) sheet (0.50 μm) was placed on top of each sample and a glass-plate was used to press the material. The glass-plate was removed and the material was polymerized directly on top of the PET sheet. A fully charged LED light (Celalux 2®, VOCO GmbH) was used to cure the samples with 10 s and 20 s irradiation (850 mW/cm²) in addition to the 40 s irradiation with a curing cycle of 5 s irradiation (310 mW/cm²) as soft start followed by 35 s (850 mW/cm²). The powerdensity was checked before each curing by a radiometer (Bluephase meter; Ivoclar Vivadent, Schaan, Liechtenstein). The samples were then removed from the mould and the excess was removed. Contamination was avoided when manipulating the samples by the use of nitrile gloves. The analysis of the DC in the FT-Raman spectroscope started at approximately 1 min after the irradiation was finished.

To investigate the influence of the mould material on the DC of dental composite resins, samples of an experimental composite with a well-controlled composition were also investigated. Ten samples (thickness = 6 mm; Ø = 5 mm) for each mould material (n = 30) were cured with 40 s irradiation and made by following the same procedures described for the commercial composites.

Degree of conversion

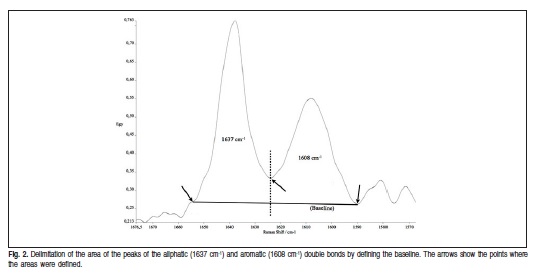

The DC was determined by using a FT-Raman spectrometer (Spectrum 2000R NIR-Raman, Perkin-Elmer®, US), equipped with an Nd:YAG-laser at near-infrared excitation of 1064 nm and an InGaAs detector. The samples were analysed with 32 scan co-addition at resolution of 4 cm-1, the spectral region was set as the mid-IR range of 4000-500 cm-1 and laser power of 1 W. The degree of conversion of each sample was determined by the following equation:

DC = (1- [ACured / AUncured]) x 100

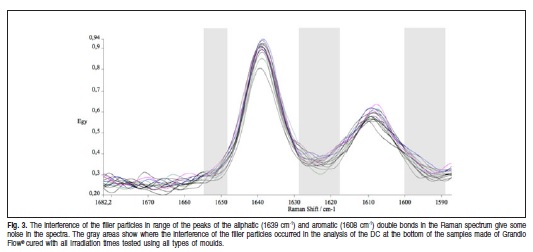

where ACured is the ratio of aliphatic (1639 cm-1) to aromatic (1608 cm-1) carbon double bond peak areas of the Fig. 2. Delimitation of the area of the peaks of the aliphatic (1637 cm-1) and aromatic (1608 cm-1) double bonds by defining the baseline. The arrows show the points where the areas were defined. cured samples, and A Uncured is the equivalent ratio for the material before the polymerization process.

The degree of conversion of the commercial composites was analyzed at the bottom of the samples (Figure 2). Due to the well-controlled composition of EXPM, the samples were made thicker than those of the commercial composites to allow additional measurements. Therefore, additionally to the bottom, EXPM samples were also analyzed at4 sites randomly selected around the samples' surfaces in contact with the mould materials, at approximately half way distance from top to bottom (Figure 2).

Statistical analysis

The statistical analysis was performed using IBM® SPSS® Statistics, version 19 (SPSS, Inc., IBM Company, Armonk, NY, US). One-way ANOVA and Tukey's post hoc test were used to analyze the data of the DC of the samples made with all three composite resins. In addition, the Independent paired t-test was used to compare the DC at the bottom of the samples of Grandio® and Grandio Flow®. The level of significance was set as p<0.05.

Results

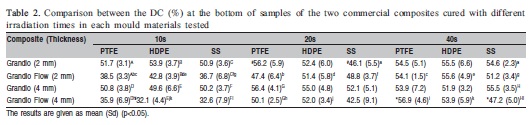

The DC at the bottom of the two commercial composites cured with 10 s, 20 s and 40 s irradiation time in each mould material is detailed in Table 2.

The comparison between the DC of the samples cured in each mould material showed that when 20 s irradiation was used, the DC of the 2-mm-thick samples of Grandio® cured in the SS mould was significantly lower than those cured in the PTFE mould. The same trend was found for the 4-mm-thick samples of Grandio Flow® cured with 40 s irradiation (p<0.05) (Table 2).

Comparison of the DC between the two commercial composites showed that the DC of the samples of Grandio Flow® was significant lower than those of Grandio® when cured with 10 s irradiation, independently of the mould material and the thickness of the samples (p<0.05) (Table 2). The increase in irradiation time to 20 s restricted the difference between Grandio® and Grandio Flow® to the 4-mm-thick samples cured in the PTFE mould. With 40 s irradiation, there as a significant difference between the DC of Grandio® and Grandio Flow® only when the 4-mm-thick samples were cured in the SS mould.

The comparison between the DC resulted from each irradiation time tested showed that for the samples of Grandio®, a significant difference of DC was found only when the 2-mm-thick samples were cured in the SS mould. The DC with 20 s irradiation was significantly lower than with 40 s irradiation (p<0.05) (Table 2). For the samples of Grandio Flow®, 10 s irradiation resulted in a DC significantly lower than the DC of the samples cured with 20 s and 40 s, independently of the mould material and the thickness of the samples. The exception was only for the 4-mm-thick samples cured in the SS mould, where the DC of the samples cured with 10 s differed only from those irradiated with 40 s (p<0.05) (Table 2). In addition, there was no significant difference between the DC of the samples cured with 20 s and 40 s, independent of the mould material (p<0.05) (Table 2).

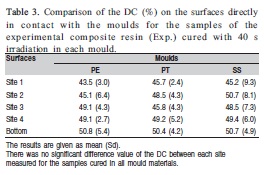

The DC at the bottom of the experimental composite showed that the DC did not differed significantly from those of the commercial composites (p<0.05) (Table 2 and 3). The results for the DC values for the experimental composite on the sites in contact with the mould (i.e. the four sites and bottom) showed no significant differences between each mould materials tested (p<0.05) (Table 3).

Discussion

The scope of this investigation was to assess whether the type of mould material used for the preparation of the samples could affect the DC on their surfaces directly in contact with the mould walls. DC analyzed with Raman spectroscopy can be performed by calculating the area or the hight of the peaks representing the aliphatic and the aromatic double bonds. Both methods have already been shown providing similar values of DC27. The former method was used in the present work, as shown in Figure 2. However, the determination of the area can be tricky, due to the interference in the spectrum of the double bonds peaks generated by the filler particles (Figure 3). Therefore, the choice of the points to determine the baseline and also the point to separate the aliphatic and/or aromatic double bonds areas could become shadowed by the peak of the filler particles. As a result, variations of the DC within the samples cured in the same conditions can be found (Figure 3). In the present work, the choice of the points to determine the areas of each spectrum was defined in the same range not exceeding 5 cm-1 from each point in all spectrum to standardise the evaluation.

Different values of DC of samples cured in different mould materials have already been shown in the literature23. Harrington and Wilson23 have found that the depth of cure was greater for the samples cured with 10 s irradiation in the PTFE mould than in the SS mould, independent of the shade. It is worth noticing that the bottom of the samples was in contact with a non-reflecting base instead of with the mould materials, avoiding any interference on the DC at the bottom of the samples by the reflection of the light from of the mould material. Conversely, previous authors have already shown that the DC at the bottom tends to level up with that at the top with the increase of irradiation and/or power density of the light source28-31, despite of using or not a non-reflecting surface at the bottom of the moulds. In the present work, a significant difference of the DC value at the bottom of the samples between those cured in the PTFE and in the SS moulds was also found, however, only with the irradiation times higher than 10 s (Table 2). The DC of the 2-mm-thick samples of Grandio® cured in the SS mould was significant lower than those cured in the PTFE mould when cured with 20 s irradiation, whereas for Grandio Flow®, the difference was found only for the DC of the 4-mm-thick samples cured with 40 s irradiation (Table 2).

Emami, Söderholm and Berglund29 have suggested that the number of photons delivered during the light-curing (i.e. energy density) is the important factor for achieving higher values of DC. Energy density (E) is calculated by the power density (PD) x irradiation time. The same power density from the light source was used for curing all the samples, then the energy density varied only with the irradiation time. Thus, the energy densities provided by 10 s and 20 s were, respectively, 8.5 and 17 J/cm2, whereas for 40 s irradiation was 1.5 J/cm2 (5 s x 310 mW/cm2) plus 29.7 J/cm2 (35 s x 850 mW/cm2). Therefore, it could be suggested that depth of cure, which indicates the effectiveness of the conversion of the carbon-carbon double bonds at the bottom of the samples is clearly dependent on the energy density delivered by the light source.

The tests of the two commercial composites showed that they behave differently with the increase in the energy density used (Table 2). The difference between the two commercial composites is mainly the monomer content, since they have a similar volume of filler particles. Whereas Grandio® contains a proportion of Bis-GMA (Bisphenol-A glycidyldimethacrylate)/TEGDMA (Triethyleneglycol dimethacrylate monomers in its matrix, Grandio Flow® has an addition of HEDMA (1,6-exanodiol dimethacrylate), a low molecular weight monomer, to reduce the viscosity of the resin (Table 1).

With 10 s of irradiation, the values of DC of the samples made of Grandio Flow® were significant lower than those of Grandio®, throughout the analysis (Table 2). Thus, one could suggest that the addition of HEDMA in its composition may have influenced the DC instead of the type of mould material. Moreover, these results suggest that 10 s irradiation is not suitable for restorations with Grandio Flow®. The increase of the irradiation time to 20 s restricted the difference between the DC values of the two commercial composite to the 4-mm-thick samples cured in the PTFE mould, whereas 40 s restricted it to the 4-mm-thick samples cured in the SS mould. The latter was due to the lowest value of DC of Grandio Flow® achieved, compared with the other moulds.

Due to the significantly different DC values at the bottom of the samples of Grandio Flow®, when compared with those of Grandio®, a comparison between the DC at the bottom of the samples resulted from each irradiation time was also made (Table 2). The analysis showed the samples of Grandio® differed only when the samples were cured in the SS mould when the DC resulted from 20 s irradiation was much lower than that of 40 s irradiation. The samples of Grandio Flow® seem to be more affected by the irradiation time, independently of the thickness of the samples. The increase in irradiation time showed that 10 s irradiation resulted in significantly lowest DC values than 20 s and 40 s irradiation. The exception was found only for 4-mm-thick samples cured in the SS mould, when the DC of 10 s was similar of the 20 s irradiation (Table 2).

Irradiation times of 20 and 40 s have been recommended by the manufacture as the proper curing time for Grandio Flow®. However, no significant difference between the values of DC for the samples cured with 20 s and 40 s irradiation, regardless of the mould material and thickness. This finding suggests that the curing time of Grandio Flow® could be reduced by half without compromising the DC at the bottom of the samples for both 2-mm and 4 mm thicknesses.

The comparison between the DC of the three composite resins cured in each mould material tested with 40 s irradiation was also made (Tables 2 and 3). The samples of EXPM were thicker than both commercial composites, but have similar monomer mixture as Grandio®. In addition, the samples of EXPM have much lower volume of filler particles than both commercial composites. Despite their differences, the values of DC at the bottom of the samples from all three composites were similar, when cured with the same energy density (E = 31.2 J/cm2). The exception was found only for the 4-mm-thick samples cured in the SS mould, where the samples of Grandio Flow® differed significantly from those of Grandio®, as previously mentioned (Table 2).

The comparison of the DC on the different sites around the samples of EXPM showed, no significant different between the DC on the sites measured (Table 3). Thus, the results suggest that DC occurs homogeneously throughout the surfaces of the samples in contact with the mould materials.

Based on the obtained results, the hypothesis that plastic mould materials (PTFE and HDPE) would give a decreased DC on the samples' surfaces directly in contact with the mould walls compared with the SS mould was rejected. Instead, the results of the present work suggest that the differences of DC values found between the samples cured in the SS mould and those cured in the PTFE mould were mainly due to the irradiation time used to cure the samples and also to the content of the monomer mixture of the composites.

Acknowledgements

The authors would like to thank VOCO GmbH for providing all the composite resins and the light lamp and the Royal Institute of Technology for providing the FTRaman spectroscope and for manufacturing the moulds.

References

1. Zhu S, Tian Y, Hamielec AE, Eaton DR. Radical trapping and termination in free-radical polymerization of methyl methacrylate. Macromolecules. 1990; 23: 1144-50. [ Links ]

2. Asmussen E. Factors affecting the quantity of remaining double bonds in restorative resin polymers. Scand J Dent Res. 1982; 90: 490-6. [ Links ]

3. Pfeifer CS, Silva LR, Kawano Y, Braga RR. Bis-GMA co-polymerizations: influence on conversion, flexural properties, fracture toughness and susceptibility to ethanol degradation of experimental composites. Dent Mater. 2009; 25: 1136-41. [ Links ]

4. Ruyter IE, Svendsen SA. Remaining methacrylate groups in composite restorative materials. Acta Odontol Scand. 1978; 36: 75-82. [ Links ]

5. Zhu S, Tian Y, Hamielec AE, Eaton DR. Radical concentrations in free radical copolymerization of MMA/EGDMA. Polymer. 1990; 31: 154-9. [ Links ]

6. Goncalves F, Pfeifer CC, Stansbury JW, Newman SM, Braga RR. Influence of matrix composition on polymerization stress development of experimental composites. Dent Mater. 2010; 26: 697-703. [ Links ]

7. Amirouche-Korichi A, Mouzali M, Watts DC. Effects of monomer ratios and highly radiopaque fillers on degree of conversion and shrinkage-strain of dental resin composites. Dent Mater. 2009; 25: 1411-8. [ Links ]

8. Furuse AY, Mondelli J, Watts DC. Network structures of Bis-GMA/TEGDMA resins differ in DC, shrinkage-strain, hardness and optical properties as a function of reducing agent. Dent Mater. 2011; 27: 497-506. [ Links ]

9. Brandt WC, Schneider LF, Frollini E, Correr-Sobrinho L, Sinhoreti MA. Effect of different photo-initiators and light curing units on degree of conversion of composites. Braz Oral Res. 2010; 24: 263-70. [ Links ]

10. Lopes MB, Moraes RR, Gonini-Junior A, Piva E. Impact of curing protocol on the selected properties of a model bis-GMA/TEGDMA dental resin composite. Biomed Mater. 2009; 4: 025014. [ Links ]

11. Moraes RR, Brandt WC, Naves LZ, Correr-Sobrinho L, Piva E. Lightand time-dependent polymerization of dual-cured resin luting agent beneath ceramic. Acta Odontol Scand. 2008; 66: 257-61. [ Links ]

12. Chung KH, Greener EH. Correlation between degree of conversion, filler concentration and mechanical properties of posterior composite resins. J Oral Rehabil. 1990; 17: 487-94. [ Links ]

13. Ferracane JL, Antonio RC, Matsumoto H. Variables affecting the fracture toughness of dental composites. J Dent Res. 1987; 66: 1140-5. [ Links ]

14. Ferracane JL. Correlation between hardness and degree of conversion during the setting reaction of unfilled dental restorative resins. Dent Mater. 1985; 1: 11-4. [ Links ]

15. Goncalves F, Kawano Y, Braga RR. Contraction stress related to composite inorganic content. Dent Mater. 2010; 26: 704-9. [ Links ]

16. Dewaele M, Truffier-Boutry D, Devaux J, Leloup G. Volume contraction in photocured dental resins: the shrinkage-conversion relationship revisited. Dent Mater. 2006; 22: 359-65. [ Links ]

17. Ferracane JL, Greener EH. The effect of resin formulation on the degree of conversion and mechanical properties of dental restorative resins. J Biomed Mater Res. 1986; 20: 121-31. [ Links ]

18. Shin WS, Li XF, Schwartz B, Wunder SL, Baran GR. Determination of the degree of cure of dental resins using Raman and FT-Raman spectroscopy. Dent Mater. 1993; 9: 317-24. [ Links ]

19. Miyazaki M, Onose H, Iida N, Kazama H. Determination of residual double bonds in resin-dentin interface by Raman spectroscopy. Dent Mater. 2003; 19: 245-51. [ Links ]

20. Soares LES, Martin AA, Barbosa Pinheiro AL. Degree of conversion of composite resin: a Raman study. J Clin Laser Med Surg. 2003; 21: 357-62. [ Links ]

21. Tsuda H, Arends J. Raman spectroscopy in dental research: a short review of recent studies. Adv Dent Res. 1997; 11: 539-47. [ Links ]

22. Fan PL, Stanford CM, Stanford WB, Leung R, Stanford JW. Effects of backing reflectance and mold size on polymerization of photo-activated composite resin. J Dent Res. 1984; 63: 1245-7. [ Links ]

23. Harrington E, Wilson HJ. Depth of cure of radiation-activated materials—effect of mould material and cavity size. J Dent. 1993; 21: 305-11.

24. Gauthier MA, Stangel I, Ellis TH, Zhu XX. Oxygen inhibition in dental resins. J Dent Res. 2005; 84: 725-9. [ Links ]

25. International Organization for Standardization. IOf. ISO4049: 2000. Dentistry polymer - based filling, restorative and luting materials. ISO; 2000. [ Links ]

26. Ortengren U, Elgh U, Spasenoska V, Milleding P, Haasum J, Karlsson S. Water sorption and flexural properties of a composite resin cement. Int J Prosthodont. 2000; 13: 141-7. [ Links ]

27. Rueggeberg FA, Hashinger DT, Fairhurst CW. Calibration of FTIR conversion analysis of contemporary dental resin composites. Dent Mater. 1990; 6: 241-49. [ Links ]

28. Stansbury JW, Dickens SH. Determination of double bond conversion in dental resins by near infrared spectroscopy. Dent Mater. 2001; 17: 71-9. [ Links ]

29. Emami N, Soderholm KJ, Berglund LA. Effect of light power density variations on bulk curing properties of dental composites. J Dent. 2003; 31: 189-96. [ Links ]

30. Goncalves F, Calheiros FC, Witzel MF, Kawano Y, Braga RR. Effect of photoactivation protocol and radiant exposure on monomer conversion and flexural strength of a resin composite after water and ethanol storage. J Biomed Mater Res B Appl Biomater. 2007; 82: 89-92. [ Links ]

31. Emami N, Soderholm KJ. How light irradiance and curing time affect monomer conversion in light-cured resin composites. Eur J Oral Sci. 2003; 111: 536-42. [ Links ]

Correspondence:

Correspondence:

Roberto Belloti Cornelio

TANN-Building, Hansine Hansensveien 86,

9016, Tromsø, Norway

E-mail: roberto.belloti@uit.no

Received for publication: July 11, 2012

Accepted: December 10, 2012