Serviços Personalizados

Artigo

Links relacionados

Compartilhar

IJD. International Journal of Dentistry

versão On-line ISSN 1806-146X

IJD, Int. j. dent. vol.9 no.1 Recife Jan./Mar. 2010

ORIGINAL ARTICLE ARTIGO ORIGINAL

Evaluation of Knoop microhardness of nanoparticle resins according to the light curing apparatus

Avaliação da microdureza Knoop de resinas nanoparticuladas de acordo com o aparelho de luz utilizado

Paulo F Menezes FilhoI; Hélder J Cantarelli de CarvalhoII; Antonio B Vasconcelos NetoII; Renata P GuimarãesIII; Mário Alexandre Coelho SinhoretiIV; Rafael Pino VittiV

IAssociate professor, School of Dentistry, Federal University of Pernambuco

IIOral surgeon, degree awarded by the School of Dentistry, Federal University of Pernambuco

IIIDoctorate student, School of Dentistry, Federal University of Pernambuco

IVTitular professor, School of Dentistry of Piracicaba, State University of Campinas

VDoctorate student, School of Dentistry of Piracicaba, State University of Campinas

ABSTRACT

Since the introduction of composite resins, depth of polymerization has been a concern among researchers since it can adversely affect the materials' physical and mechanical properties if insufficient. This study assessed the degree of Knoop microhardness of three nanoparticle resins polymerized with four types of sources of activation. Sixty test specimens were prepared using standard curing time of 20 seconds as per manufacturers' recommendations. Those specimens were divided into four groups and further divided into subgroups according to type and type of cured resin, respectively. After microhardness test and analysis of variance (ANOVA with a significance level of 5%), results showed that the highest hardness values were observed on the top for all groups. For Groups 2, 3 and 4 in the top area and 1, 2 and 4 in the base resins, there were significant hardness differences whereas in Group 1 (base) and 2 (top) the Z350 resin showed significantly higher hardness values than the others. It was also had shown that LED appliances are as effective as those using halogen light.

Key words: Composite resins; hardness; dental materials

RESUMO

Desde a introduçaõ das resinas compostas, a profundidade de polimerização tem sido uma preocupação entre pesquisadores, uma vez que esta pode afetar as propriedades físicas e mecânicas dos materiais se for insuficiente. Este estudo avaliou o grau de dureza Knoop de três resinas nanoparticuladas polimerizadas com quatro tipos de fontes de ativação. Sessenta corpos de prova foram preparados usando o tempo padrão de 20 segundos, conforme as recomendações dos fabricantes. Estes espécimes foram divididos em quatro grupos e posteriormente divididos em subgrupos de acordo com o tipo e tipo de resina usada, respectivamente. Após o teste de microdureza e análise de variância (ANOVA com um nível de significância de 5%), os resultados mostraram que os mais altos valores de dureza foram observados no topo, para todos os grupos. Para os grupos 2, 3 e 4 na área do topo e 1, 2 e 4 na base da resina, houve diferença significante de dureza, enquanto que no grupo 1 (base) e grupo 2 (topo) a resina Z350 mostrou valores de dureza significativamente maiores que as outras. Mostrou-se também que os aparelhos LED são tão eficazes quanto àqueles que utilizam luz halógena.

Palavras-chave: Resinas compostas; dureza, materiais dentários.

INTRODUCTION

Since the introduction of composite resins in the 1960s the demand for aesthetic restorations has increased significantly1. Early on, the composite resins had numerous drawbacks such as low wear resistance and brittleness, large polymerization shrinkage, asperities, micro leakage, adhesive failure, thermal expansion as well as broken chemical bonds due to water1,2.

Some research and studies led manufacturers to develop materials with better mechanical properties and more satisfying aesthetic results while researchers worked on depth of polymerization and material hardness3-5 which resulted in dental composites with a higher amount of inorganic matrix and ever smaller particle loads and new sources of polymerization; in turn, the materials' main deficiencies were corrected and/or eliminated1.

A better understanding of composite resins and correct techniques for insertion and polymerization added to improvements performed over time on the materials. Growing demand for aesthetic restoration greatly increased the use of these composites even for rear teeth where, historically, the amalgam had been the material of choice6-8. This was made possible by the introduction of hybrid and micro hybrid resins in the market since they had higher mechanical strength and longer life in restoration procedures7.

More recently, nanotechnology developments applied to composite resins gave them better physical and mechanical properties due to higher concentration, different formats and disposition of load particles as well as changes in the constitution of the organic matrix of these materials9. Among existing resins, the ones that stand out are nanoparticulate resins having only nanometric sized particulates in their composition, and nano-hybrid resins that include nanoparticulates in their formulae. As an example, we have the nanoparticulate resins Filtk Supreme and Filtek Z350 which, basically, as any other composite resins, have three phases: an organic matrix, a bonding agent and load particulate. These inorganic particulates can be found in two formats: scatter - silica particulates, about 20nm in size; and aggregates, nanoagreggates of silica-zircon that behave as a sole structure, measuring an average of 75 nm7.

Dental composites are directly influenced by insertion techniques, photoactivation, type and intensity of light used4,5. A correct polymerization must use the proper luminescence, wavelength and period of exposure which are adequate to the photoactivator apparatus in use as well as the insertion of the composite resin whose thickness must not be beyond 2 mm; insertion and photoactivation must be performed incrementally or layer by layer in order to minimize polymerization shrinkage1,2,4,10.

The early composite resins were chemically polymerized. However, these materials presented many drawbacks, among them high polymerization shrinkage, low wear resistance, superficial staining and few aesthetic possibilities4,10,11. In the early 1970s, ultraviolet light was used to deploy photoactivation10. Polymerization using this system also had inconveniences such as limited cure depth as well as the possibility of injuries to both the practitioner and the patient11. Nowadays, photopolymerization is done by invisible light (halogen light and LED)4,10.

Despite the many advances, this technology still suffers from a few limitations which are responsible for most cases of clinical failures; it can negatively affect the materials' physical and mechanical properties by reducing hardness and by causing adhesive failure, micro leakage and post-surgery sensitivity, among others1-3, The intensity of the light emitted by the photoactivators is a decisive factor in their performance and has direct influence on the proper polymerization of the composites4.

Main disadvantages of halogen light equipment are heat generation and lamp degradation, resulting in less light intensity and thus, insufficient polymerization of the composites12,13. A more recent technology has been studied for application in photoactivators. Light Emitting Diodes, LEDS, are more advantageous than halogen light and these advantages include longer lamp useful life, less heat, spectrum emission around 450 and 490 nm (coinciding with the absorption peak of camphorquinone, the photoinitiator most commonly present in composite resins) and a more efficient conversion of energy into light12,13.

This study aimed to evaluate Knoop hardness above and under using three nanoparticulate composite resins, photoactivated with four different appliances emitting invisible light, three of them LEDs and one halogen light.

MATERIALS AND METHODS

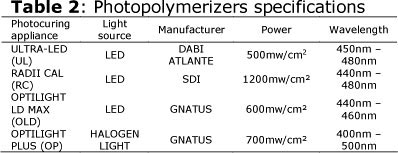

This study used three types of composite resins and four types of photoactivating appliances; details can be found in Tables 1 and 2, respectively.

Sixty test samples were made, each one measuring 2 mm thickness and 5 mm in diameter. Standardization was achieved with a metallic matrix specially designed for this experiment. The composite resin was inserted into the matrix in one single portion using a #2 Duflex spatula. After insertion, the resin was pressed down for one minute with the spatula to help the resin settle inside the cavities of the metallic matrix. We coated the matrix with Vaseline in order to facilitate removal of the samples. All samples were photopolymerized for 20 seconds as per manufacturers' recommendations; the tip of each appliance was in direct contact with the polyester matrix that had been placed over the resin. Light intensity of all photopolymerization appliances used was measured beforehand with a radiometer (Hilux - Dental Curing Light Meter), order #950 - 750. A dot mark was made on the surface of each specimen with a black felt tip pen. Low rotation polishing work was performed on the sides of each sample for removal of excess resin with emery discs (3M ESPE). The samples were then placed in plastic containers and sent for hardness analyses.

Test samples were divided into four groups according to photoactivating appliance used; Group 1: Ultra-led (Dabi-Atlante); group 2: Radii Cal (SDI); group 3: Optilight LD MAX (Gnatus); and group 4: Optilight Plus (Gnatus). And three subgroups, according to composite resin used: Sub-group 1: Filtek Z350 (3M-ESPE); subgroup 2: ICE (SDI); and sub-group 3: Brilliant new line (Vigodent).

The samples were submitted to Knoop microhardness testing using a HMV-2 Shimadzu microhardness tester, under a 50 gram load and 10 seconds for each spot analyzed. Five spots were analyzed in each area of the sample (top and base), beginning with a spot in the very center of each surface and then four other spots around the first.

RESULTS

Results were submitted to variance analysis (ANOVA) and Krustall-Wallis, at 5.0% significance level.

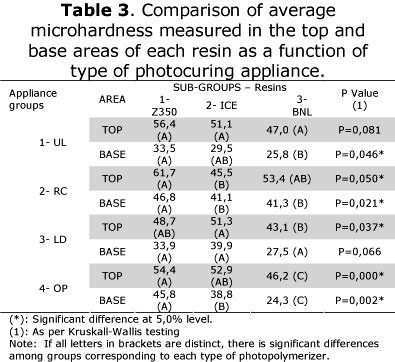

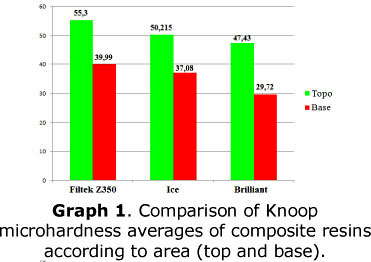

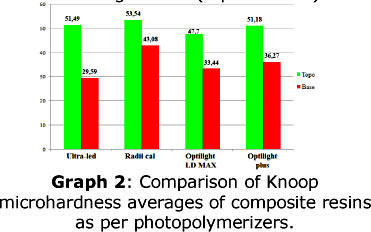

Table 3 and Graphs 1 and 2 show values reached by the resins and respective photopolymerization appliances, on the top and base areas.

DISCUSSION

Studies have shown that hardness is found in the lesser depths regardless of type of composite and method of photoactivation4,5,1416. This conclusion agrees with this study as far as hardness in the lesser depths; however, it can be seen in Table 3 that the same base, Filtek Z350 resin photoactivated with the LED appliance Radii Cal had higher microhardness than the Brilliant resin polymerized with the Optilight LD MAX appliance on top. This agrees with the assertion that microhardness depends on the type of composite and type of photoactivation. This was also the conclusion reached by the studies performed by Pereira et al.17.

To Firoozmand et al.15, halogen light appliances are efficient for depths of 2, 3 and 4 mm, and LED appliances only for 2 and 3 mm depths, considering the fact that we used a single insertion with 2 mm thickness in order to prevent sub-polymerization at the test sample base area. However, Lopes et al.9 concluded that polymerization depth using the Ultrablue (LED) appliance surpassed the practitioners' often used 2 mm thickness, with good results.

MARTINS et al.10 concluded that the color of the composite used has no influence on degree of Knoop hardness in 2 mm thick test specimens.

Busato et al.3, Firoozmand et al.15 and Pereira et al.17, concluded that the halogen light appliance offers best microhardness results than LED appliances. Lopes et al.9, Bosquiroli et al.12 and Strang et al.18, on the other hand, contest these results by asserting that the LED appliances are as effective as the halogen light appliances with which we concur since the results obtained in this study showed similar results. For Ganime et al.13, best hardness values, according to their studies, were obtained with a LED light source, with significant results over halogen light.

Santos et al.16 evaluated microhardness as a function of polymerization time using 20 and 40 seconds as well as three types of photocuring units. They concluded that the 40 second exposure had best microhardness results over the 20 second photocuring exposure with the three appliances used. Gonçalves et al.8 concluded that the photoactivation time of 60 seconds increased the degree of composite conversion vis a vis the 20 second photoactivation period; therefore, it may be that by increasing the polymerization time there will also be increased polymerization depths and hardness values, i.e., the increase in polymerization time is directly proportional to the hardness degree we observed. Guimarães et al.19 categorically stated that photoactivation time must be respected regardless of type of composite resin used in order to maintain its properties.

CONCLUSIONS

According to the methodology applied to this study and taking into consideration the results obtained, we can say that:

- Knoop microhardness values for all groups were higher on the top than on the base área;

- Only on Groups UL (top) and OLD (base) did we not note statistically significant differences in hardness among the resins studied.

- For Groups RC, OLD and OP we noted that there were hardness differences in the top area whereas in Group 2 (RC) the Z350 resin had significantly higher hardness differences over the remainder, which had no differences. As for Group 3, the Z350 and ICE resins had significantly higher hardness than Brilliant. In Group 4 (OP), we saw the same results as for Group 3.

- For the UL, RC and OP Groups, we noted that the resins also showed differences as far as hardness in the base area, whereas Group 1 (UL), the Z350 resin showed significantly higher hardness than the Brilliant resin; in this group, the ICE resin had an intermediate behavior without differentiation from the remainder. In Group 2 (RC), resin Z350 had significantly higher hardness over the remainder and the latter showed no differences among them, i.e., showed similar behavior to the top area. In Group 4 (OP) we noted significant differences among the three resins, i.e., Z350 > ICE > Brilliant.

- Although there is no consensus among researchers on which photopolymerization type is the most efficient, in this study the LED type appliances were shown to be as effective as the halogen light ones.

REFERENCES

1. Busato ALS, Barbosa NA, Bueno M, Baldissera RA. Denstística: restaurações em dentes posteriores. Porto Alegre: Artes Médicas, 1996. 302 p. ISBN (enc. [ Links ])

2. Macêdo JL, Menezes Filho PF, Silva RB, Sinhoreti MAC. Avaliação da dureza KNOOP em função do tipo de aparelho fotopolimerizador. Int J Dent 2002; 1(2): 107-118. [ Links ]

3. Busato ALS, Valim RR, Arossi G, Reichert L, Sonza Q, Melo G. Métodos de fotopolimerização. Stomatos 2007;13(24): 45-52. [ Links ]

4. Consani S, Pereira SB, Sinhoreti MAC, Correr Sobrinho L. Efeito dos métodos de fotoativação e de inserção sobre a dureza de resinas compostas. Pesqui Odontol Bras 2002; 16(4):355-360. [ Links ]

5. Gomes Filho EB, Menezes Filho PF, Silva CLV, Sinhoreti MAC. Evaluation of the hardness KNOOP of composite resin in function of the variation of the tecnique of complementary polimerazition. Acta Odontol Venezolana 2008; 46 (1). [ Links ]

6. Amaral CM, Castro AKBB, Pimenta LAF, Ambrosano GMB. Efeito das técnicas de inserção e ativação da resina composta sobre a microinfiltração e microdureza. Pesqui Odontol Bras 2002; 16(3):257-262. [ Links ]

7. Cardoso RM, Maia GHS, Melo CA, Guimarães RP, Menezes Filho PF. Aplicação clínica das resinas de nanotecnologia. Odontol Clín-Científ 2008; 7(4): 357362. [ Links ]

8. Gonçalves LS, Spazzin AO, Consani S, Mesquita MF, Galafassi D, Carlini Júnior B. Influência do tempo de fotoativação na resistência à flexão de compósitos restauradores. RFO 2008;13(2):56-60. [ Links ]

9. Lopes LG, Souza JB, Andrade FR, Ferreira PR, Freitas GC, Barnabé W, et al. Profundidade de polimerização de resinas híbrida, micro e nanoparticuladas utilizando luz halógena ou LED de segunda geração. Robrac 2006; 15(39). [ Links ]

10. Martins F, Delbem ACB, Santos LRA, Soares HLO, Martins EOB. Microdureza de resinas em função da cor e luz halógena. Pesqui Odontol Bras 2002; 16(3): 246250. [ Links ]

11. Sensi LG. Efeito da unidade de fotoativação (halógena/leds) no selamento marginal de restaurações de resina composta. [Dissertação]. Florianópolis (SC): Universidade de Santa Catarina; 2003. [ Links ]

12. Bosquiroli V, Franco EB, Pereira JC, Navarro MFL, Mondelli RFL. Fotopolimerização de resina composta com luz halógena e LED. RGO 2006; 54(2):129-133. [ Links ]

13. Ganime MM, Giorgi MCC, Dias CTS, Paulillo LAMS. Avaliação da dureza knoop de resina composta ativada com diferentes fontes de luz. Cienc Odonto Bras 2008; 11(3):74-80. [ Links ]

14. Cunha LA, Pagani C, Miranda CB, Teixeira SC, Silva RCSP. Efeito dos métodos de fotoativação sobre a dureza Knoop de compósitos odontológicos. PGR-Pós Grad Rev Fac Odontol São José dos Campos 2001; 4(3). [ Links ]

15. Firoozmand LM, Araújo RM, Balducci I. Influência de fotopolimerizadores de luz halógena X led azul na dureza de resina composta. Cienc Odontol Bras 2005; 8(1):67-74. [ Links ]

16. Santos LA, Turbino ML, Youssef MN, Matson E. Microdureza de resina composta: efeito de aparelhos e tempos de polimerização em diferentes profundidades. Pesq Odont Bras 2000; 14(1):65-70. [ Links ]

17. Pereira SK, Rastelli ANS, Souza CD, Bortoli D. Novas fontes de polimerização. RGO 2004; 52(1) [ Links ]

18. Strang ALVB, Rego MA, Liporoni PCS, Mello JB. Avaliação da microdureza de resina composta nanoparticulada, variando-se cor, sistema de fotoativação e tempo de aplicação. X Encontro Latino Americano de Iniciação Científica e VI Encontro Latino Americano de Pós-Graduação - Universidade Vale do Paraíba. 2006. [ Links ]

19. Guimarães FBR, Gomes HR, Fonseca RS, Barros LM, Marinho VA, Freitas ABDA. Influência do tempo de fotopolimerização de diferentes resinas compostas na sorpção de água. Rev Odonto Ciênc 2008; 23(1):67-71. [ Links ]

Correspondence:

Correspondence:

Paulo Fonseca Menezes Filho

Rua da Amizade, N° 109, Apto 1402

CEP: 52011-260, Recife-PE

Telephone/fax number: (+55 81) 32223459

E-mail: paulo.fmf@globo.com

Recebido em 28/11/2009

Aprovado em 18/03/2010