Serviços Personalizados

Artigo

Links relacionados

Compartilhar

Revista Odonto Ciência (Online)

versão On-line ISSN 1980-6523

Rev. odonto ciênc. (Online) vol.25 no.3 Porto Alegre Jul./Set. 2010

ORIGINAL ARTICLE

Disinfection of irreversible hydrocolloid impressions with sodium hypochlorite steam: assessment of surface roughness and dimensions of gypsum models

Desinfecção de moldes de hidrocolóide irreversível com vapor de hipoclorito de sódio: avaliação dimensional e rugosidade superficial dos modelos de gesso

Carmem Dolores V. Soares de MouraI; Walter Leal de MouraII; Fabiana Mantovani Gomes FrançaIII; Gregório Antonio Soares MartinsIV; Lorenna Bastos L. Verde NogueiraIV; Raquel Virgínia ZanettiV

IDepartment of Prosthodontics, Faculty of Dentistry, Federal University of Piauí, Teresina, PI, Brazil

IIDepartment of Surgery, Faculty of Dentistry, Federal University of Piauí, Teresina, PI, Brazil

IIIGraduate Program in Dentistry, São Leopoldo Mandic School of Dentistry, Campinas, SP, Brazil

IVDental School, Federal University of Piauí, Teresina, PI, Brazil

VSão Leopoldo Mandic School of Dentistry, Campinas, SP, Brazil

ABSTRACT

PURPOSE: To evaluate the surface roughness and dimensional stability of types III and IV gypsum models, obtained from irreversible hydrocolloid impressions after disinfection with 5.25% sodium hypochlorite steam.

METHODS: The impressions to obtain type III and type IV gypsum models were divided into 3 groups: Group 1 (disinfection with 5.25% sodium hypochlorite steam for 10 minutes); Group 2 (simulated disinfection with distilled water steam) and Group 3 (no treatment). To measure the dimensional changes with a digital caliper, 36 models (18 for each type of gypsum) were cast according to a stainless steel master model with four pillars. For the surface roughness measurement, 36 gypsum models were cast from the impressions of the polished stainless steel platform. The data were analyzed using ANOVA and Tukey's test (α=1%).

RESULTS: There was no statistically significant difference in linear dimensions or surface roughness when the different disinfection treatments were compared (Groups 1, 2 and 3), for all types of gypsum.

CONCLUSION: The disinfection treatments with sodium hypochlorite steam and distilled water steam for irreversible hydrocolloid impressions did not significantly affect the dimensional stability and surface roughness of the types III and IV gypsum dental models.

Key words: Biosafety; sodium hypochlorite; gypsum

RESUMO

PROPOSIÇÃO: Avaliar o comportamento dimensional e rugosidade superficial de modelos de gesso tipos III e IV, obtidos em moldes de hidrocolóide irreversível desinfetados com vapor de hipoclorito de sódio 5,25%.

METODOLOGIA: Os moldes para obtenção dos modelos de gesso tipo III e tipo IV foram designados: Grupo 1 (desinfecção com vapor de hipoclorito de sódio 5,25% por 10 minutos); Grupo 2 (simulação de desinfecção com vapor de água destilada) e Grupo 3 (sem tratamento). Para medição das alterações dimensionais, moldou-se modelo mestre de aço inox com quatro pilares e confeccionou-se 36 modelos (18 para cada tipo de gesso) e as distâncias foram mensuradas com paquímetro digital. Para leitura da rugosidade, confeccionaram-se 36 modelos a partir de moldes de plataforma de aço inox polida e avaliou-se a superfície dos gessos com rugosímetro. Os dados foram submetidos à análise de variância e teste de Tukey (α=1%).

RESULTADOS: Na medição das dimensões lineares entre pilares e leitura da rugosidade superficial, não houve diferença estatística significativa, quando comparados os tipos de tratamento (Grupos 1, 2 e 3) em nenhum dos tipos de gesso.

CONCLUSÃO: Os tratamentos dos moldes de hidrocolóide irreversível com vapor de hipoclorito de sódio e água destilada não afetaram significantemente a estabilidade dimensional e a rugosidade superficial dos modelos de gesso tipo III e tipo IV.

Palavras-chave: Biossegurança; hipoclorito de sódio; gesso

Introduction

If dental impressions are contaminated by saliva and blood in the clinical environment, it is easy for microorganisms to cross-infect gypsum models in the laboratory (1-3). So it is essential to find a suitable method for disinfection to eliminate microorganisms without reducing the quality of the gypsum models (4). Irreversible hydrocolloid (IH) is one of the most noteworthy impression materials because of its relatively low cost and hydrophilic property. However, this hydrophilic nature may cause dimensional changes and increase surface roughness when the material is subjected to mold-disinfection procedures, which is reflected in the gypsum models produced from IH impressions (5).

In order to eliminate changes resulting from the disinfection of impressions, some methods have been proposed to decontaminate the models, such as immersion of gypsum models in 0.525% sodium hypochlorite solution (6), or application of a disinfectant spray (7). Other methods include incorporating chemical compounds in the plaster mixture (8) or use of plasters that contain disinfectant (9). However, these methods have resulted in changes in the properties of gypsum casts, such as lower compressive strength and lower surface hardness (10,11).

Disinfection of irreversible hydrocolloid impressions can also cause significant changes, especially in the repro- duction of details and surface smoothness of the gypsum models (2,4,6,7,11,12). However, it is more appropriate because it prevents that contaminated materials are transferred to the laboratory (13). IH impressions are vulnerable to dimensional and surface deformations, when compared to elastomer impressions (4), especially when immersed in sodium hypochlorite for longer than 10 min (2,4,14,15). The immersion of IH impressions in 1% sodium hypochlorite for a maximum of 10 min has been advocated to minimize these changes, but this method was ineffective at controlling microbes (16).

Some studies have used sodium hypochlorite at a 5.25% concentration because it acts quickly, however, it causes deterioration of the surface of IH impressions when immersed in this solution (17). One way of applying sodium hypochlorite is by using a spray, which reduces changes in the gypsum casts, but this method is not recommended for effective disinfection of HBV (Hepatitis B Virus) and HIV (Human Immunodeficiency Virus) (18).

Methods of disinfection of impressions and models are quite diverse in their nature, and therefore there is a need to standardize techniques that have proven antimicrobial efficacy and that do not alter the quality of the gypsum models (3). The technique of disinfecting IH using 5.25% sodium hypochlorite steam, without the need for immersion of the mold, seems better suited to that purpose (19). The method is microbiologically effective, although the results of this treatment still need to be assessed in casts produced from these impressions. The disinfection of impressions with 5.25% sodium hypochlorite steam could be used because of its antimicrobial efficacy and also to eliminate or minimize undesirable effects that immersion of irreversible hydrocolloid impressions would cause in gypsum models.

The purpose of this study was to evaluate the linear dimensional changes and surface roughness of type III (Herodent®) and type IV (Durone®) gypsum models obtained from irreversible hydrocolloid impressions (Hydrogum®) disinfected with 5.25% sodium hypochlorite steam.

Methodology

Experimental assessment of linear dimensions

The sample consisted of 18 type III (Herodent® Vigodent S/A Ind. e Com. Ltda. Rio de Janeiro-Brasil) and 18 type IV (Durone® Dentsply Ind. e Com.Ltda, Rio de Janeiro-Brazil) gypsum models, obtained from irreversible hydrocolloid impressions (Hydrogum®, 55896 lot, Zhermack s.p. A, Rovigo-Italy) of a stainless steel master model. Three groups were tested: Group 1 (disinfection of impressions with 5.25% sodium hypochlorite steam for 10 min); Group 2 (simulated disinfection with distilled water steam for 10 min) and Group 3 (no treatment – placement of impressions in the nebulizer box for 10 min).

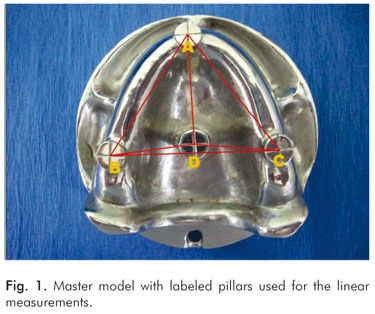

A stainless steel master model was used as a reference model (Art Nacnaya Ltda., São Paulo, SP, Brazil), simulating an edentulous maxillary arch, with 3 mm-high pillars positioned in the midline (A), second molars (B and C), and center of the palatal concavity (D). Grooves were made at the top of each pillar to form a cross, whose intersection was the point of measurement (Fig. 1).

A 5 mm-thick layer of utility red wax (Spinelli, Ind. Bras. Pirassununga, SP, Brazil) was used to provide the interior space needed for the impression material to have a uniform thickness. A wax-free area was also provided at the base of the model, functioning as a stop for the tray. One self-curing acrylic tray (Vipi Mold®, Dental Vipi, Ind. Bras. Pirassununga, SP, Brazil) was made from this wax-coated master model. In order to make the tray suitable for the impression and disinfection procedures, its body was perforated with 2 mm holes and supports were placed on the handle and on the tray's external surface.

The irreversible hydrocolloid was manipulated according to the manufacturer's instructions (9 g of powder to 18 mL of water; mixing time: 30 s; working time: 1 min) using distilled water at 23º C. After it had hardened (3 min), the impression was removed from the master model to receive the assigned treatment.

Disinfection treatment of the impressions

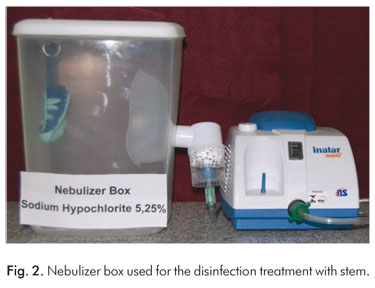

Group 1 impressions were placed in the Nebulizer box: a sealed plastic box (15 cm diameter, 30 cm height) adapted so the impression could be fixed on the upper part of the lid, containing continuous 5.25% sodium hypochlorite steam provided by a domestic nebulizer mask (ST Super-NS®. NS Indústria de Aparelhos Médicos Ltda, São Paulo, SP, Brasil) fitted inside the box (Fig. 2). The 5.25% free chlorine sodium hypochlorite steam, pH 8.6 to 9.4 (batch 164, Laboratório de Controle de Qualidade da Fórmula & Ação, São Paulo, SP, Brasil), was applied for 10 min (19). After the disinfection period, the impressions were rinsed in distilled water for 15 s to remove the impregnated hypochlorite (10).

For Group 2 samples, a simulation of disinfection was carried out using the same technique but replacing the 5.25% sodium hypochlorite with distilled water. The impressions in Group 3 remained in the Nebulizer Box for 10 min.

Gypsum models production

Type IV and Type III gypsum were used, with the following water/powder ratios: Durone®: 21 mL/100 g and Herodent®: 30 ml/100 g. The powder was added to water, stirred gently for a few seconds and then vacuum manipulated (7) (Vacumixer® – Polidental Ltda., Cotia, SP, Brazil) for 30 s. The gypsums were placed in impressions in increments with the aid of a vibrator.

The relative humidity during the preparation of the samples was kept within the parameters recommended by the ADA Specification #25 (2000): 50±10%, with a standard temperature interval of 21 to 23ºC. The gypsum remained in contact with the mold for 45 min. To prevent syneresis of the IH (13), it was stored in humid atmosphere provided by a humidifier described as follows: a sealed, square, plastic box, 16 cm-wide and 8 cm-high, containing a floor of cylinder PVC pipes (4 cm high and 3 cm diameter), filled with distilled water up to a level close to the top of the cylinders (19).

After the model was separated from the mold, the gypsum samples were identified and examined for the existence of bubbles and imperfections, and those considered defective were discarded (5 samples). The selected samples (for Group 1, Group 2 and Group 3) were cut using a plaster cutter and cleaned with distilled water in an ultrasound device (Thorton-INPEC Eletrônica Ltda. Vinhedo, SP-Brasil) for 15 s, to remove any residual gypsum. They were then identified and placed in sealed boxes until measurement.

Measurement of the linear distance between pillars

Forty eight hours after the samples had been prepared, the measurements of the lines between the pillars were recorded using a digital caliper 0.01 mm/.150 mm/.0005"6" (Mitutoyo, Indústria Brasileira, São Paulo, SP, Brazil). Each measurement was repeated 6 times by the same operator resulting in a mean value.

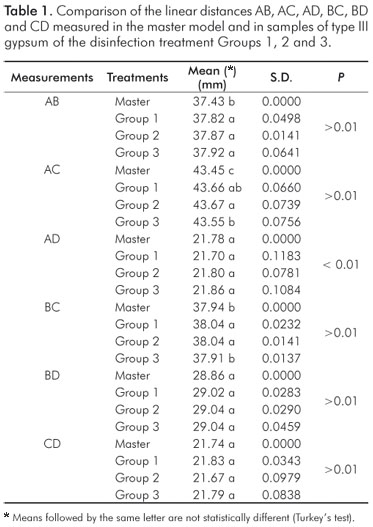

The following distances (expressed in mm) between the center of the pillars' crosses were measured: Distance 1 – the midline (A) X right molar (B); Distance 2 – midline (A) X left molar (C); Distance 3 – mid (A) X center of the palate (D); Distance 4 – right molar (B) X left molar (C); Distance 5 – right molar (B) X center of the palate (D); Distance 6 – left molar (C ) X center of the palate (D). The means were submitted to ANOVA and compared by the Tukey's test.

Surface roughness test

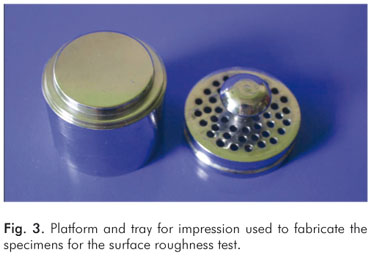

The sample consisted of 18 type III and 18 type IV gypsum plates, obtained from irreversible hydrocolloid impressions of a standard polished stainless steel platform. A cylindrical polished stainless steel platform (2.8 cm diameter) was used as standard, and a stainless steel tray was made on top of this (Arte Nacnaya Ltda. São Paulo, SP, Brazil) with internal space of 5 mm and with perforations in its body for IH retention. Space was not left at the base of the platform, leaving this area in contact with the tray, to serve as a stopping point (Fig. 3).

The manipulation of IH, the disinfection procedure, simulation of disinfection and the waiting procedures were similar to those described in the previous methodology. The plaster samples were examined for the existence of bubbles and other imperfections and selected for measurement.

Forty eight hours after the samples had been prepared, the roughness of the surfaces of the gypsum platforms were measured using a rugosimeter (Surfcorder SE 1700, Kosakalab, Japan). The selected unit was the micrometer (µm) and the parameters were adjusted in Ra. This variable describes the total roughness of the surface and can be defined as the arithmetic mean of all the pores within the measurement length. The profilometer was set at the device's standard roughness, and the measurement length was 4 mm (5 X 0.8 cut-off). Six readings were carried out for each unit of Groups 1, 2 and 3 and also for the standard platform. The means were analyzed using ANOVA and compared using Tukey's test.

Results

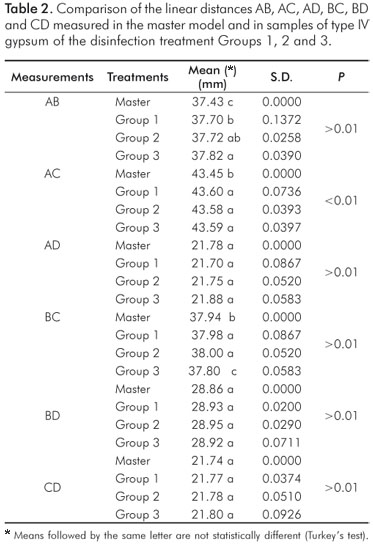

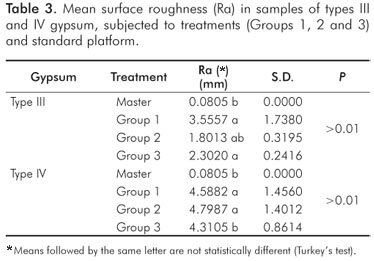

The results of measurement of linear dimensions were grouped in Tables 1 and 2. The results of the mean values of roughness measurements are shown in Table 3. There was no statistically significant difference in linear dimensions or surface roughness when the different disinfection treatments were compared (Groups 1, 2 and 3), for all types of gypsum.

Discussion

Many researchers have adopted methods of pouring impressions without using a previous decontamination procedure: they only decontaminate the models by applying disinfectant solutions directly on the model (7) or adding disinfectant to the gypsum mixture (8,10,11). Our study did not incorporate sodium hypochlorite in the gypsum model, therefore we used a methodology that inhibits possible changes in the physical properties of gypsum. Models were produced from impressions that had been previously rinsed and disinfected, and gypsum pouring was carried out in the traditional manner, without the incorporation of disinfectants in the mixture or subsequent disinfection of the model.

Many authors have reported dimensional changes and surface porosity in gypsum models produced after disinfection of HI impressions immersed for more than 10 min and concluded that this method is inadequate (4,14,15). However, the immersion of the IH impressions for up to 10 min in 1% sodium hypochlorite has shown clinically insignificant changes in gypsum models (20), but did not have an effective antimicrobial activity (16).

Considering IH's intrinsic potential of retaining micro- organisms (21), some researchers (17,22) have used 5.25% sodium hypochlorite, for up to 10 min, with the objective of optimizing antimicrobial efficacy. However, this resulted in significant surface deterioration of gypsum models (22). The 5.25% concentration is recommended as long as the sodium hypochlorite does not come into direct contact with the impression (10). In this experiment, 5.25% sodium hypochlorite was applied for 10 min as a steam, with no direct contact of the solution with the impression, to prevent deterioration. Our study demonstrated that the surface roughness of Group 1 samples (type III and type IV gypsum treated with sodium hypochlorite) were not significantly different when compared with samples from Groups 2 and 3 (not treated).

Other studies have suggested this method of disinfecting irreversible hydrocolloid impressions using sodium hypochlorite spray to reduce the changes in the gypsum and to ensure better dimensional accuracy and surface quality of the models (18). However, when disinfection by spray was assessed, it was found to be ineffective from a microbiological point of view so they used a different method: applying the spray four times with the mold placed for 10 min in a sealed plastic bag, which resulted in effective disinfection. This shows that the method of application is important (23). The method of application of disinfectant as a steam atmosphere, provided by the Nebulizer Box in our research and the position of the impression, prevented undesired accumulation of hypochlorite in the impression.

Samples of type III and type IV gypsum from IH impressions disinfected with 5.25% sodium hypochlorite steam (Group 1) did not show any statistically significant changes in linear dimensional stability of the lines AD, BD and CD for either type of gypsum, when compared to samples from untreated impressions (Groups 2 and 3) and the master model. Furthermore, the results did not differ when distances AB in Groups 1, 2 and 3 were compared for type III gypsum and AC for type IV gypsum, which demonstrates that the linear dimensional behavior of these lines was not different in the treated and untreated groups. For the distances AB, AC and BC, the proposed treatments (Groups 1, 2 and 3) differed from the master model, proving that the samples not treated with sodium hypochlorite steam also behaved differently from the master model, so the hypochlorite was not responsible for these changes.

To assess the surface roughness of the studied gypsums after disinfection of the impression, the models were compared with the master model made with a smooth and polished metal surface with a roughness reading of approximately 0.0805 µm. The high mean roughness values found for both types of gypsum (in Groups 1, 2 and 3) when compared to the reference values, were also found in other studies (24). The mean roughness values in those studies were between 2 and 4 µm in samples of special gypsum cast in IH impressions, which proves the influence of this material on the surface roughness of the models. Therefore, the IH itself may have been responsible for the significant difference between the roughness of the standard platform and gypsum samples. However, the treatment of irreversible hydrocolloid impressions with 5.25% sodium hypochlorite steam (Group 1) did not cause changes in surface roughness of the types III and IV gypsum samples when compared with groups not treated with hypochlorite (Groups 2 and 3).

Our study shows that the production of models made of type III (Herodent®) and type IV (Durone®) gypsum without linear dimensional changes and with suitable surface texture from IH impressions (Hydrogum®) that have been steam disinfected with 5.25% sodium hypochlorite (Group 1), when compared with treatments in groups 2 and 3 is of scientific importance. Previous studies (2,10,12,22,23) disinfected the IH impressions with techniques that produced unsuitable gypsum models, especially in terms of surface characteristics, rendering a porous gypsum that is poor in details.

The technique adopted in our study enabled us to use 5.25% sodium hypochlorite solution on the IH impression, a procedure that has hitherto been contraindicated (10,17). IH has disadvantages when compared to elastomers: its ability to retain microorganisms (21) and its dimensional instability against environmental changes (5). Therefore, it is essential to develop specific techniques to disinfect impressions made of this material. In the methodology adopted, the high concentration of 5.25% sodium hypochlorite was used to improve the bactericidal action necessary to disinfect the IH impression, with the steam provided by the Nebulizer Box. Relative humidity was kept close to 100%.

Conclusions

It can be concluded that the disinfection of irreversible hydrocolloid impressions (Hydrogum®) with 5.25% sodium hypochlorite steam for 10 min (Group 1) promoted dimensional stability and surface roughness of type III (Herodent®) and type IV (Durone®) gypsum models that was similar to untreated groups (Groups 2 and 3). Therefore, we recommend this technique as a treatment option for the disinfection of irreversible hydrocolloid impressions (Hydrogum®).

References

1. Sofou A, Larsen T, Fiehn NE, Öwall B. Contamination level of alginate impressions arriving at a dental laboratory. Clin Oral Invest 2002;6:161-5. [ Links ]

2. Taylor RL, Wright OS, Maryan C. Disinfection procedures: their effect on the dimensional accuracy and surface quality of irreversible hydrocolloid impression materials and gypsum casts. Dent Mater 2002;18:103-10. [ Links ]

3. Muller-Bolla M, Lupi-Pégurier L, Velly AM, Bolla M. A survey of disinfection of irreversible hydrocolloid and silicone impressions in European Union Dental Schools: Epidemiologic study. Int J Prosthodont 2004;17:165-71. [ Links ]

4. Peutzfeldt A, Asmussen E. Effect of disinfecting solutions on surface texture of alginate and elastomeric impressions. Scand J Dent Res 1990;98:74-81. [ Links ]

5. Anusavice KJ. Phillips Materiais Dentários. 11.ed. Rio de Janeiro: Elsevier; 2005. [ Links ]

6. Abdullah MA. Surface detail, compressive strength, and dimensional accuracy of gypsum casts after repeated immersion in hypochlorite solution. J Prosthet Dent 2006;95:462-8. [ Links ]

7. Stern MA, Johnson GH, Toolson LB. An evaluation of dental stones after repeated exposure to spray desinfectant. Part I: abrasion and compressive strength. J Prosthet Dent 1991;65:713-8. [ Links ]

8. Breault LG, Paul JR, Hondrum SO, Christensen LC. Die Stone disinfection: incorporation of sodium hypochlorite. J Prosthodont 1998;7:13-6. [ Links ]

9. Schutt RW. Bactericidal effect of a disinfectant dental stone on irreversible hydrocolloid impressions and Stone casts. J Prosthet Dent 1989;62:605-7. [ Links ]

10. Boden J, Likeman P, Clark R. Some effects of disinfecting solutions on the properties of alginate impression material and dental Stone. Eur J Prosthodont Rest Dent 2001;9:131-5. [ Links ]

11. Abdelaziz KM, Combe EC, Hodges JS. The effect of disinfectant on the properties of dental gypsum: 1. Mechanical properties. J Prosthodont 2002;11:161-7. [ Links ]

12. Tan HK, Hooper PM, Buttar IA, Wolfaardt JF. Effects of disinfecting irreversible hydrocolloid impressions on the resultant gypsum casts. Part II – Dimensional changes. J Prosthet Dent 1993;70:532-7. [ Links ]

13. Craig RG, Powers JM, Wataha JC. Materiais Dentários. Propriedades e Manipulação. 7.ed. São Paulo: Livraria Editora Santos; 2002. [ Links ]

14. Jones ML, Newcombe MA, Bellis H, Bottomley J. The dimensional stability of self-disinfecting alginate impressions compared to various immersion regimes. Angle Orthod 1990;60:123-8. [ Links ]

15. Ralph WJ, Gin SSL, Cheadle DA, Harcourt JK. The effects of disinfectants on the dimensional stability of alginate impression materials. Austr Dent J 1990;35:515-7. [ Links ]

16. Santos EM, Jorge AO. Desinfecção de moldes de hidrocolóide irreversível e modelos de gesso com hipoclorito de sódio: eficiência e estabilidade dimensional. Rev Odontol UNESP 2001;30: 107-19. [ Links ]

17. Tullner JB, Commette JA, Moon PC. Linear dimensional changes in dental impressions after immersion in disinfectant solutions. J Prosthet Dent 1988;60:725-8. [ Links ]

18. Bergman B, Bergman M, Olsson S. Alginate Impressions materials, dimensional stability and surface detail sharpness following treatment with disinfectant solutions. Swed Dent J 1985;9:255-62. [ Links ]

19. Moura CDVS. Avaliação da eficácia do hipoclorito de sódio na desinfecção dos moldes de hidrocolóide irreversível [dissertação]. Campinas (SP): Centro de Pesquisas Odontológicas São Leopoldo Mandic; 2006. [ Links ]

20. Durr DP, Novak EV. Dimensional stability of alginate impressions immersed in disinfecting solutions. J Dent Child 1987;54:45-8. [ Links ]

21. Samaranayake LP, Hunjan M, Jennings KJ. Carriage of oral flora on irreversible hydrocolloid and elastomeric impression materials. J Prosthet Dent 1991;65:244-9. [ Links ]

22. Vanderwalle KS, Charlton DG, Schwartz RS, Reagan SE, Koeppen RG. Immersion disinfection of irreversible hydrocolloid impressions with sodium hypochlorite. Part II: Effect on gypsum. Int J Prosthodont 1994;7:315-22. [ Links ]

23. Kern M, Rathmer RM, Strub JR. Three-dimensional investigation of accuracy of impression materials after disinfection. J Prosthet Dent 1993;70:449-56. [ Links ]

24. Kenter FMS, Davidson CL. Surface roughness of dental stone casts from alginate impressions. J Dent 1986;14:23-8. [ Links ]

Correspondence:

Correspondence:

Carmem Dolores Vilarinho Soares de Moura

Rua São Pedro 3274 / Apto 902 – Frei Serafim

Teresina, PI – Brasil

64001-914

E-mail: carmemdvsm@uol.com.br

Received: November 23, 2009

Accepted: June 22, 2010

Conflict of Interest Statement: The authors state that there are no financial and personal conflicts of interest that could have inappropriately influenced their work.