Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RGO.Revista Gaúcha de Odontologia (Online)

versão On-line ISSN 1981-8637

RGO, Rev. gaúch. odontol. (Online) vol.60 no.1 Porto Alegre Jan./Mar. 2012

ORIGINAL / ORIGINAL

Dimensional accuracy of impression material used in complete dentures

Fidelidade dimensional de materiais de moldagem funcional em prótese total

Carla Fernandes Rodrigues PAIVA I; Milton Edson MIRANDA I; Marcelo Lucchesi TEIXIERA I; José Renato PINTO II; Karina Andrea Novaes OLIVIERI I

I Faculdade São Leopoldo Mandic, Curso de Odontologia, Programa de Pós-Graduação em Prótese Dentária. Rua José Rocha Junqueira, 13, Campinas, 13045-755, Swift, Campinas, SP, Brasil

II Universidade Estadual de Campinas, Faculdade de Odontologia, Departamento de Prótese. Piracicaba, SP, Brasil

ABSTRACT

Objective

The aim of this research was to compare the degree of dimensional stability and accuracy of Sapphire (Bosworth, Skokle, Illinois, EUA), which is an ethyl methacrylate acrylic resin, with polyvinyl siloxane (ADSIL-Vigodent, Rio de Janeiro, Brazil), a very accurate material of worldwide use.

Methods

The materials were tested by two techniques, the one-step putty and two-step putty-wash impression techniques. Stone casts were produced from impressions of an aluminum master cast of an edentulous maxilla. The samples were divided into four groups of 15 impressions each: Group 1 - putty-wash impression with Sapphire (putty) and Adsil Fluido (wash); Group 2 - putty impression with Sapphire; Group 3 - putty impression with Adsil Regular (putty); Group 4 - putty-wash impression with Adsil Regular (putty) and Adsil Fluido (wash). Measurements were done by the B251 Mitutoyo Coordinate Measuring Machine (Mitutoyo Co., Suzano, Brazil). The statistical treatment included calculating the mean, variance and standard deviation of the samples. The significance level was set at 5% (p<0.05). The distances found for each group were compared with those of the master cast by the t-test.

Results

Sapphire putty impressions presented the best dimensional stability. On the other hand, polyvinyl siloxane putty (Adsil) presented significant dimensional variations in samples produced from putty and putty-wash impressions. When Sapphire (Bosworth, Skokie, Illinois, EUA) and Adsil were used together (putty-wash), Sapphire (Bosworth, Skokie, Illinois, EUA) improved the results of the putty-wash impressions.

Conclusion

In conclusion, Sapphire (Bosworth, Skokie, Illinois, EUA) is a reliable and stable material that can be used for complete denture impressions.

Indexing terms: Acrylic resins. Complete denture. Dental impression technique.

RESUMO

Objetivo

Comparar o nível de fidelidade e precisão do Sapphire (Bosworth, Skokle, Illinois, EUA), uma resina acrílica modificada, com um polivinilsiloxano (Adsil - Vigodent, Rio de Janeiro, Brasil), um material considerado de alta fidelidade e amplo uso.

Métodos

Os materiais foram empregados em duas técnicas: moldagem simples e moldagem dupla. Os modelos em gesso foram construídos a partir de moldes obtidos do modelo padrão metálico de alumínio que reproduz uma maxila edêntula. Foram estabelecidos 4 grupos de 15 moldagens assim divididos: Grupo 1 - Sapphire reembasado com Adsil Fluido; Grupo 2 - Sapphire com camada única; Grupo 3 - Adsil Regular com camada única e Grupo 4 - Adsil Regular mais Adsil Fluido com camada dupla. As medidas foram realizadas por um aparelho de medição por coordenadas B251 (Mitutoyo Co., Suzano, Brasil). Na análise estatística foram calculados a média, variância e o desvio padrão das amostras (nível de significância <0,05). Em seguida foi feita uma comparação da distancia encontrada em cada grupo com o valor padrão através do teste t para uma amostra.

Resultados

O Sapphire (Bosworth, Skokie, Illinois, EUA), em moldagem simples, apresentou melhores resultados em relação à estabilidade dimensional. Ao contrário do silicone de adição (Adsil, Rio de Janeiro, Brasil) que apresentou variações dimensionais significativas nos modelos obtidos por moldagem simples e também em moldagem dupla. O Sapphire (Bosworth, Skokie, Illinois, EUA) melhorou os resultados do silicone de adição ao ser misturado com este em moldagem dupla.

Conclusão

Pode-se concluir que o Sapphire (Bosworth, Skokie, Illinois, EUA) é um material de moldagem fiel e de uso viável para moldagens em Prótese Total.

Termos de indexação: Resinas acrílicas. Prótese total. Técnica de moldagem odontológica.

INTRODUCTION

Rehabilitation with complete denture will be successful if the different stages of its fabrication are done correctly, from planning to delivery. Impressions are very important strategically, because they expose the clinical situation to laboratory personnel, allowing the fabrication of accurate and representative casts. Accuracy is directly proportional to the adaptation of the future denture to the oral mucosa, which in turn reflects the success of the complete denture.

The first impression material described in the literature was the wax used by Pfaff in 1756. The first reversible hydrocolloid was used in 1925 and pastes based on zinc oxide and eugenol were used for the first time in 1930. Then, in 1950, silicones and mercaptans became available. Since then, many impression materials have been developed for anatomical and functional impressions1.

Today, many dental impression materials are available in the market. Most impression materials have tried to accomplish two important objectives: accurate results for the professional who uses them and chemical inertness for the patient. Additionally, patients want pleasant-tasting materials that stay inside the mouth as little as possible to avoid discomfort. Meanwhile, professionals want materials that are easy to handle and inexpensive, and have all the physical-chemical properties necessary for an excellent impression2.

Dentures must have mechanical, biological and aesthetic quality. They should stay in the correct position, withstand functional tensions, and be comfortable3. Because of these goals, the technique used for fabricating complete dentures requires two impressions: anatomical and functional4.

Ideal impression materials should produce accurate impressions, settle quickly and not deform when removed from the mouth4.

With the advancement of technology, it is now possible to make digital impressions by scanning the affected region. At first, digital impression may seem like fiction, but with the emergence of new technologies that improve information technology systems, soon it may be one more option for producing complete denture impressions5.

Considering the great variety of impression materials, a rigorous assessment of their dimensional accuracy is necessary to provide professionals who wish to achieve the best clinical results the theoretical and practical information they need to choose the best materials. Hence, this work assessed the dimensional stability of two materials and the effect of impression technique on functional, complete-denture impressions.

METHODS

Special type-IV stone casts were produced from impressions of an aluminum master cast (Figure 1) reproducing an edentulous maxilla. Three holes in the shape of inverted cones were made on this master cast: two on the maxillary tuberosities of both sides and one on the anterior region of the matrix, exactly on the midline.

Individual trays were fabricated for the master cast. The relief was done by adapting a 3-mm polystyrene board in a vacuum laminator. When the polystyrene relief was ready, a perforated stock tray was used to produce an alginate (Jeltrate Plus, Dentsply, Petrópolis, Brazil) impression. The individual acrylic trays were allowed to rest for at least 24 hours after fabrication, giving the resin time to settle.

Fifteen impressions were made for each of the four groups using the following techniques and materials: Group 1 - two-step putty-wash impression with Sapphire (putty) and Adsil Fluido (wash); Group 2 - one-step putty impression with Sapphire; Group 3 - one-step putty impression with Adsil Regular (putty); Group 4 - two-step putty-wash impression with Adsil Regular (putty) and Adsil Fluido (wash).

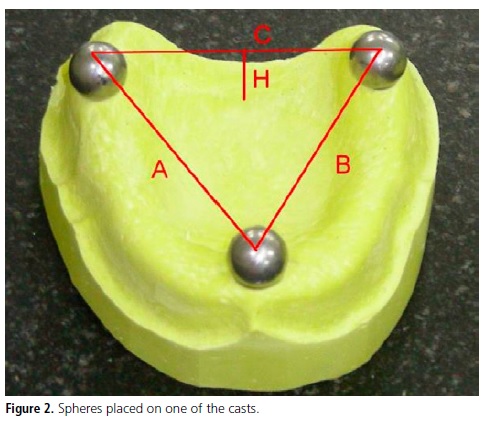

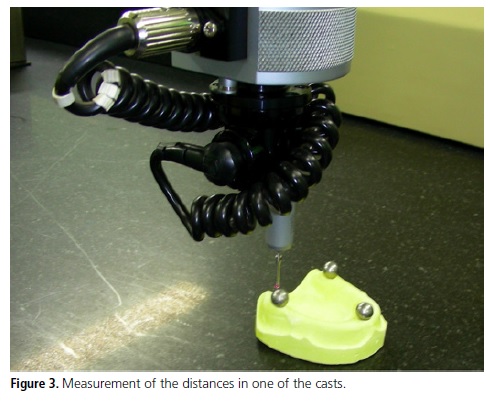

Three spheres were placed on the casts produced from autopolymerizing acrylic impressions. The distances between each two spheres were called A, B and C. The height H (perpendicular to the ABC plane) was the distance between the midpoint between the two tuberosities and the palatal midline. The measurements were done by the B251 Mitutoyo coordinate measuring machine (Mitutoyo Co.) (Figures 2 and 3).

Statistical analysis included the calculation of the mean, variance and standard deviation of the distances. The significance level was set to 5% (p<0.05). The distances found for each group were compared with those of the master cast by the t-test.

The study was approved by the Research Ethics Committee of Faculdade São Leopoldo Mandic according to the recommendations put forth by the Declaration of Helsinki (2000) and in compliance with Brazilian laws. Submission was not required because the study did not involve living animals (CEP #2006/0208).

RESULTS

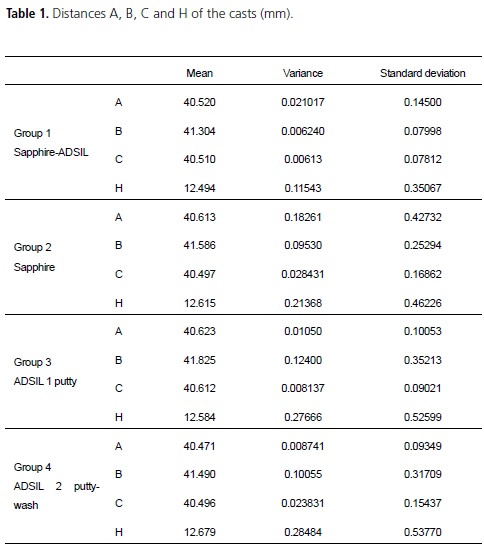

The mean, variance and standard deviation of the distances between the points of the stone casts by group are shown in Table 1.

Table 2 shows the differences between the individual distances of the points in the casts and those of the master cast.

The mean distances of each group were compared with those of the master cast by the t-test. All Saphire-Adsil distances were statistically equal to those of the master cast. The Saphire distances were also similar, except for distance B, which was a little longer than that of the master cast. The putty and putty-wash Adsil groups had greater distance variations. Distances A and H of Adsil alone were statistically equal to those of the master cast. However, distances B and C were statistically longer than those of the master cast. Distances C and H of putty-wash Adsil were equal to those of the master cast but distances A and B were shorter and longer, respectively, than those of the master cast.

DISCUSSION

The fabrication stages of complete dentures are like the links of a chain. If one fails, the result will probably be unsuccessful.

Functional impressions of edentulous patients are essential for the denture to adapt well. Good adaptation also requires appropriate technique and quality materials. The ideal material should meet many requirements. One of them is impressions with good dimensional stability for casts to be as accurate as possible6-8.

The most commonly used materials for the production of functional, complete-denture impressions are addition silicones (polyvinyl siloxane) and polyethers. Factors that may deform impressions include the professional, technique, material or deformed impression tray. The acrylic resin trays used in this study were fabricated individually from the master cast, reducing variations associated with this step of the process9. Most professionals use individual trays for functional impressions10.

Impression techniques can be divided into onestep putty, one-step putty-wash and two-step puttywash impressions. Putty-wash impressions are more accurate because they minimize the gaps caused by the contraction of the impression material during polymerization. The first step of the two-step putty-wash impression technique requires a heavy-body material (putty), which has high stability and low polymerization contraction, and the second step requires a light-body material (wash), whose fluidity produces accurate and very detailed impressions11. All putty-wash impressions made in this study used the two-step technique12-14.

The distances of the master cast and stone casts were measured under constant temperature and moisture to avoid contraction or expansion of the materials stemming from these factors. The coordinate measuring machine makes very accurate measurements, resulting in conclusive results with the reliability associated with the technique14.

Putty-wash impressions with addition silicones with and without relief produced casts with better dimensional stability than those produced from putty impressions. However, a study in the literature reported otherwise, that is, putty-wash impressions deformed more than putty impressions5.

Statistical analyses were done to compare the distances of the stone casts and the master cast. The distances of the Sapphire group were similar to those of the master cast, except for one of the distances. The distances of the Sapphire-Adsil group were all statistically equal to those of the master cast. However, the distances of the putty and putty-wash Adsil groups were not so similar to those of the master cast. Hence, not only was Sapphire better than the other materials, but it also improved the results of Adsil when used together. This test in particular did not consider if the sample distribution was normal, so it could be done in samples smaller than 30 specimens.

The comparison of many impression materials (alginates, condensation silicone, addition silicone, polyethers and polysulfide) in the literature resulted in contradictory reports. Studies are not in agreement with respect to the most dimensionally stable impression material; some prefer addition silicones15-16 while others prefer polyether17.

Sapphire has the following disadvantages: first, it is malodorous. Organoleptic properties cannot be measured but its malodor seems to be unanimous18-19; second, addition silicone is easier to work with than Sapphire. Many impressions have been lost by researchers while working with the latter20; third, its setting time is longer than that of other materials. Sapphire takes longer to settle and this is not a favorable characteristic in a clinical setting; fourth, addition silicone is more common21 and can be easily found in most distributors of dental supplies, contrary to Sapphire.

Finally, more studies are needed to assess the wettability of Sapphire and its ability to reproduce fine details.

CONCLUSION

Sapphire putty impressions have good dimensional stability since all but one (B) of the distances measured in casts produced from them were statistically equal to those of the master cast. Sapphire also improved the results of addition silicone when combined in putty-wash impressions.

Collaborators

CFR PAIVA was responsible for the experimental work and wrote the manuscript. ME MIRANDA supervised the study, reviewed the text and helped to write the manuscript. ML TEIXIERA described the Methods and helped to write the manuscript. JR PINTO was responsible.

REFERENCES

1. Domitti SS, Mesquita MF, Cardoso LAM. Variação da técnica de moldagem periférica. RGO - Rev Gaúcha Odontol. 1997;45(2):107-10. [ Links ]

2. Tamaki T. Dentaduras completas. 4ª ed. São Paulo: Sarvier; 1988.

3. Alves NC, Gonçalves HHSB. Cera fluida: uma alternativa para moldagem funcional em prótese total. PCL. 2001;3(15):432-7.

4. Telles D, Hollweg H, Castellucci L. Prótese total convencional e sobre implantes. 2ª ed. São Paulo: Editora Santos; 2004.

5. Christensen GJ. The challenge to conventional impressions. J Am Dent Assoc. 2008;139(3):347-9.

6. Saizar P. Prostodoncia total. Buenos Aires: Mundi; 1972.

7. Anusavice KJ. Phillips materiais dentários. 10ª ed. Rio de Janeiro: Guanabara Koogan; 1998.

8. Abdelaziz KM, Combe EC, Hodges JS. The wetting of surface-treated silicone impression materials by gypsum mixes containing disinfectants and modifiers. J Prosthodont. 2005;14(2):104-9.

9. Petrie CS, Walker MP, Williams K. A survey of U.S. prosthodontists and dental schools on the current materials and methods for final impressions for complete denture prosthodontics. J Prosthodont. 2005;14(4):253-62.

10. Hyde TP, McCord JF. Survey of prosthodontic impression procedures for complete dentures in general dental practice in the United Kingdom. J Prosthet Dent. 1999;81(3):295-9.

11. Gennari Filho H, Vedovatto E, Mazaro JVQ, Assunção WG, Santos PH. Avaliação da qualidade de superfície de moldes obtidos a partir de duas técnicas de moldagem utilizando-se três marcas de alginato. Cienc Odontol Bras. 2005;8(4):39-48.

12. Felton DA, Cooper LF, Scurria MS. Predictable impressions procedures for complete dentures. Dent Clin North Am. 1996;40(1):39-51.

13. Cook WD, Liem F, Russo P, Scheiner M, Simkiss G, Woodruff P. Tear and rupture of elastomeric dental impression materials. Biomaterials. 1984;5(5):275-80.

14. Michalakis KX, Bakopoulou A, Hirayama H, Garefis DP, Garefis PD. Pre-and post-set hydrophilicity of elastomeric impression materials. J Prosthodont. 2007;16(4):238-48.

15. Valle AL, Coelho AB, Scolaro JM. Avaliação do comportamento morfodimensional de materiais de moldagem utilizados em implantes dentais. Rev Fac Odontol Bauru. 2001;9(1/2):41-8.

16. Chen SY, Liang WM, Chen FN. Factors affecting the accuracy of elastometric impression materials. J Dent. 2004;32(8):603-9.

17. Dounis KS, Dounis G, Ditmyer MM, Ziebert GJ. Accuracy of successive casts for full-arch fixed prostheses. Int J Prosthodont. 2010;23(5):446-9.

18. Thongthammachat S, Moore BK, Barco MT 2nd, Hovijitra S, Brown DT, Andres CJ. Dimensional accuracy of dental casts: influence of tray material, impression material, and time. J Prosthodont. 2002;11(2):98-108.

19. Walker MP, Petrie CS, Haj-Ali R, Spencer P, Dumas C, Williams K. Moisture effect on polyether and polyvinylsiloxane dimensional accuracy and detail reproduction. J Prosthodont. 2005;14(3):158-63.

20. Miranda ME. Reabilitação oral através da prótese total. RGO - Rev Gaúcha Odontol. 1990;38(6):478-82.

21. Lee CJ, Bok SB, Bae JY, Lee HH. Comparative adaptation accuracy of acrylic denture bases evaluated by two different methods. Dent Mater J. 2010; 29(4):411-7.

Correspondence to:

Correspondence to:

CFR PAIVA

e-mail: rodrigues.cf@uol.com.br

Received on: 30/3/2010

Final version resubmitted on: 8/10/2010

Approved on: 20/1/2011