Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RSBO (Online)

versão On-line ISSN 1984-5685

RSBO (Online) vol.8 no.3 Joinville Jul./Set. 2011

ORIGINAL RESEARCH ARTICLE

Abrasive wear of two glass ionomer cements after simulated toothbrushing

Márcia Furtado Antunes de FreitasI; Leandro Jum ImaiI; César Antunes de FreitasI; Eduardo Carlos BianchiII; Carina Thaís de AlmeidaI; Ismar Eduardo Martins FilhoIII

I Department of Operative Dentistry, Endodontics and Dental Materials, Bauru Dental School, University of Sao Paulo – Bauru – Sao Paulo – Brazil

II Department of Mechanical Engineering, Bauru School of Engineering, Sao Paulo State University – Bauru – Sao Paulo – Brazil

III Department of Pediatric Dentistry, Orthodontics and Community Dentistry, Bauru Dental School, University of Sao Paulo – Bauru – Sao Paulo – Brazil

ABSTRACT

Introduction and objective: Glass ionomer cement, which was first introduced in Dentistry in 1972, presents good qualities such as aesthetics, fluoride release and adhesion to dental tissues. Because of its preventive characteristics regarding to dental caries, glass ionomer cement has been used for Atraumatic Restorative Treatment (ART), as reported by Frencken and Holmgren 6, meeting the principles announced by the World Health Organization (WHO) for application to large population groups without regular access to dental care. Material and methods: In this present study, the abrasive wear strength of two glass-ionomer cements (Vidrion R® and ChemFlex®) was evaluated through toothbrushing machine. Classic® toothbrushes with soft bristles and Sorriso® dentifrice were also used for the study. Results: Student-t test showed significant difference between both groups, with tobs value = 9.4411 at p < 0.05. Conclusion: It can be concluded that the wear rate caused by toothbrush/dentifrice was higher for Vidrion R® (52.00 mg) than ChemFlex® (5.57 mg).

Keywords: abrasive wear; glass ionomer cements; dental materials.

Introduction

In Dentistry, several dental restorative materials have been evaluated regarding to resistance to abrasive wear through toothbrushing assays. Among these materials, glass ionomer cements, introduced in 1972 by Wilson and Kent 15, combine a number of important properties, such as adequate mechanical resistance, good adhesion to dental tissues, capacity of fluoride release, biocompatibility, aesthetic, etc. In the following year, Kent et al. 9 registered that the material had raised great interest among dentists. Due to the preventive features regarding to dental caries, glass ionomer cements have been used in the approach so-called atraumatic restorative treatment (ART), reported in 2001 by Frencken and Holmgren 6, meeting the principles announced in 1994 by the World Health Organization (WHO) 16 for application to large population groups without regular access to dental care.

Volunteers linked to the Group of Study and Research of Children's Lead Poisoning (short GEPICCB) of the city of Bauru, which comprises Bauru Dental School and the Hospital for Rehabilitation of Craniofacial Anomalies (short HRAC) both of the University of Sao Paulo, have performed the treatment using Vidrion R® glass ionomer cement, whose presents a relatively low cost compared with other similar cements. Few studies on this material's resistance to wear, either by toothbrushing or by other method, have been conducted. The simultaneous assessment of two glass ionomer cements with different values regarding to resistance to wear due to toothbrushing could also include the aspects of the costs involved, an important factor for public health, as pointed out by Almeida et al. 1.

The aim of this study was to evaluate the resistance to abrasive wear of two glass ionomer cements through toothbrushing machine and use of a dentifrice.

Material and methods

The environmental conditions of temperature and humidity required by the American Dental Association (ADA) specification no. 66 2, in 1989, for dental glass ionomer cements; and, the requirements of the International Organization for Standardization (ISO) technical specification 14569-1, established in 2007, regarding to toothbrushing assays were applied in this order during the specimen constructions and tests. The specimen dimensions also follow the specification of both aforementioned institutions.

The two restorative glass ionomer cements tested were ChemFlex® (Dentsply DeTrey GmbH, Germany) and Vidrion R® (distributed by S. S. White Ltd., Rio de Janeiro, RJ, Brazil). By considering the manufacturers' instructions on the powder/liquid ratio as 1:1, we used three powder portions (total of 0.4641 g) and three liquid drops (total of 0.1155 g) for ChemFlex® and two powder portions (total of 0.2700 g) and two liquid drops (total of 0.0684 g) for Vidrion R®, to construct the specimens with the required dimensions.

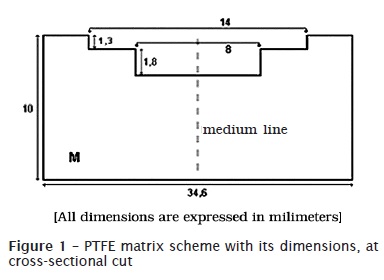

In all weighing operations, an analytical scale (model 2662 Sartorius-Werke, Gottingen, Germany), with accuracy of 0.0001 g and maximum capacity of 200 g, was used. The mixture of the components was executed following the manufacturer' instructions for both materials. Therefore, ChemFlex® was mixed for 1.5 min and Vidrion R® for 1 min, by using a cement spatula #24. The resulting mass was immediately inserted within the cylindrical cavity of the matrices constructed in polytetrafluorethylene (PTFE) whose dimensions are seen in figure 1. This was executed through the central orifice of a supporting metallic stainless steel plate connected to the matrix up to fill it with a small excess of material.

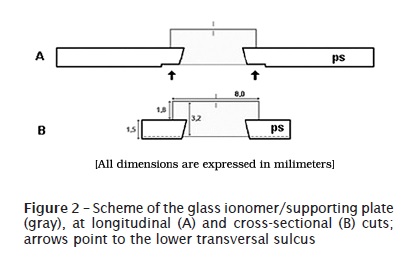

A polyester matrix strip was placed on the plastic mass, which was fitted in the lower transversal sulcus (0.1 mm deep) of the aforementioned supporting plate. Then, digital pressure was applied onto a glass coverslip placed over the polyester strip, for 60 seconds. Following, this load was replaced by a 250 g cylinder up to the material's setting, after 10 minutes, starting from the material mixture. Just after the polyester strip removal, glass ionomer's exposed surface was protected through cavity varnish (Vidrion V®, same manufacturer of Vidrion R®). This was left to dry for 2 minutes, when the excess material was removed through scalpel blade. Following, the matrix was removed from the supporting plate, exposing the others material's surfaces, where the cavity varnish was similarly applied. After 15 minutes, each specimen (glass ionomer/supporting matrix) was immersed in deionized water within a flask until reaching 24 hours, the time when the material was considered as mature.

Since ISO technical specification 8 states that, for any study on materials' wear through toothbrushing, reference specimens be produced with polymethylmethacrylate (PMMA) without crosslinking agent, four of these specimens were constructed.

Figure 2 shows the glass ionomer/supporting plate set and its respective dimensions.

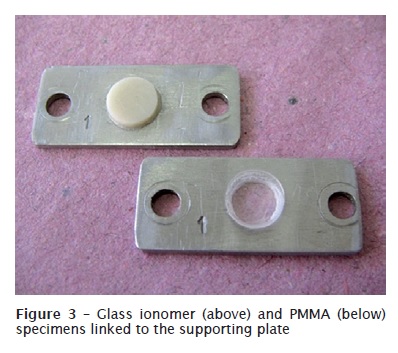

Figure 3 displays the glass ionomer and PMMA specimens with similar dimensions, as required by ISO 8.

After 24 hour immersion in deionized water, each specimen's upper surface (glass ionomer or PMA) was flattened by 600-grit and 1000-grit wet sandpaper, always under copious irrigation with deionized water, up to the specimen height was reduced from 1.8 mm to 1.5 mm. To maintain the parallelism between the specimen's upper and lower (supporting plate) surfaces, each one was inserted into a 1.5 mm thickness slot of an auxiliary stainless steel rule placed under every wet sandpaper. Following, the specimen was washed in a conventional ultrasound device, with deionized water, for 1 minute, and stored in its flask until toothbrushing assay, after 7 days.

Because the toothbrushing machine (figure 4) contained 10 specimens at a time, we divided the specimens into two sets of eight glass ionomer and two PMMA specimens.

Immediately after the assay, each one of the ten specimens was dried with common absorbent paper for 10 seconds and left to dry spontaneously for 20 minutes, over the work counter, exposed to the aforementioned environmental conditions. Following, after all the specimens were consecutively weighed three times and the arithmetical mean of the obtained values, expressed in micrograms, was considered as the specimen's mass. The supporting plate mass was subtracted from each value shown at the scale; therefore, the initial mass value of each specimen was registered.

We use soft-bristle toothbrushes model Classic® (Colgate-Palmolive Ind. e Com. Ltda., Sao Paulo, SP, Brazil), without their handles. Each toothbrush covered one specimen. Therefore, toothbrushing machine interior space comprises a supporting bar for the toothbrushes. The toothbrushes (long fixed into the machine's arms, which moved from anterior to posterior, resulting in back and forth movements (cycles).

The dentifrice used in this study (Sorriso®, Colgate-Palmolive Ind. e Com. Ltda., Sao Paulo, SP, Brazil) was mixed to deionized water, at 1:2 ratio, in weight, as required by ISO 8, composing a suspension placed within ten plastic syringes inside the toothbrushing machine.

We defined that the specimens' position in the machine's supporting bar would be identified by numbers from 1 to 10, consecutively from left to right of an observer's front view. Therefore, positions 1 to 8 had the ionomer glass specimens and 9 to 10 the PMMA specimens.

Also, we defined that the dentifrice solution would be directed towards the first seven glass ionomer specimens as well as the last reference specimen (number #10). The other toothbrushes left (numbers #8 and #9) were irrigated only by deionized water coming from the syringes.

The device was regulated to inject over each specimen, at every 2 minutes, an amount of 0.4 ml of either deionized water or dentifrice solution. The amplitude of the toothbrush movement was adjusted for 20 mm and the load on the specimen was about 300 grams-force (about 3N), according to the manufacturer. Toothbrushing was performed at a velocity of 4.6 cycles per second, for approximately 6 hours, up to complete a total of 100,000 cycles, at room temperature of 37ºc.

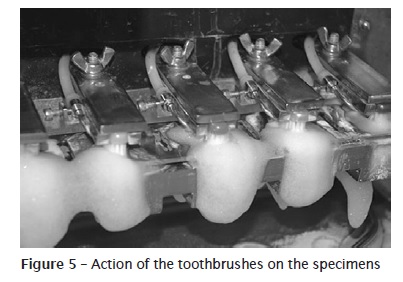

Figure 5 shows the action of some toothbrushes on the specimens. After toothbrushing, each specimen was washed in deionized water, for about 5 seconds, up to visualization of dentifrice elimination. Following, the specimen were again washed in the ultrasound device to be weighed as aforementioned cited. Then, the final mass value was recorded.

After the required homocedascity (homogeneity of variance) was confirmed, only the first seven specimen values of each group were submitted to statistical analysis by Student's t test. The last three specimen values will be demonstrated only for supporting the study's discussion.

Results

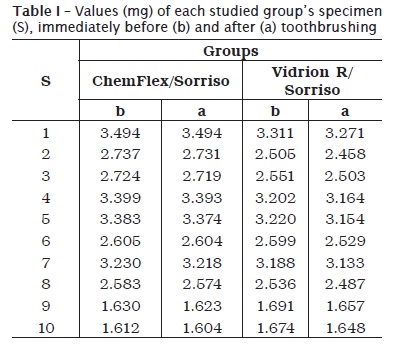

The values (milligrams) of 10 specimens' mass of each group – ChemFlex/Sorriso (CS) and Vidrion R/Sorriso (VS) – before and after toothbrushing are shown in table I.

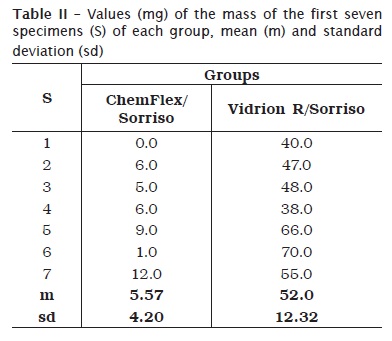

Statistical analysis was performed only in the first seven specimens of each group. The mean values and standard deviation are seen in table II.

After the homogeneity of variance was confirmed in both groups, the values were submitted to Student's t test, which found a significant difference between groups, with value of tobs = 9.4411, at p < 0.05.

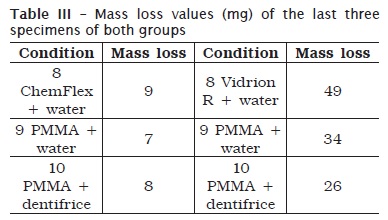

Accordingly, the wear rates caused by the toothbrush/dentifrice used on both glass ionomer were statistically different. A greater mass loss was found for Vidrion R® (52.00 mg) than ChemFlex® (5.57 mg). Table III shows the last three specimens' mass loss values of the tested groups.

Although these values were not submitted to statistical analysis, some observations could be done based on them. By analyzing the results of the glass ionomers specimens brushed only with water, ChemFlex® still presented a greater resistance to wear (9 mg) than Vidrion R® (49 mg). PMMA (already known as the most resistance material when compared to glass ionomers) underwent little wear in group 1 both with water (7 mg) and dentifrice (8 mg). However, in group 2, the material presented higher values, losing 34 mg with toothbrush+water and 26 mg with toothbrush+dentifrice.

Discussion

ISO 8 demands that in any wear analysis of restorative materials through toothbrushing, PMMA is the reference material, which is a pure acrylic resin without crosslinking agents. Therefore, the aggressiveness index (ability to promote wear) of different research's methods would enable the comparison of their results. However, generally this comparison cannot be performed, because the influencing factors are very varied, such as toothbrush load on the material, toothbrush's bristles flexibility, the amount of dentifrice abrasive particle, toothbrush's velocity on the material, toothbrushing elapsed time, and temperature during the process.

All glass ionomer specimens were always wet, because the study of Cintra et al. (2008) 3 showed that glass ionomer specimens with less abrasive resistance were those which undergone even small dryness.

The use of the scale is a simple, precise method as confirmed by Rios et al. 13.

The few studies on toothbrushing of glass ionomer used the same conditions employed in our study, employing in many times several toothbrushes, dentifrices and/or reference substrates.

Notwithstanding, our results can be only compared to those of Almeida et al. 1, in which the same materials were assessed, at the same conditions, except from the use of child dentifrices. These authors found that Vidrion R® undergone a markedly greater wear than ChemFlex® when the dentifrice Tandy® had been used; when the dentifrice Baby Barney® had been used, the material undergone similar wear.

In 1997, Fabretti et al. 5 used exclusively Plexiglass® (PMMA, Rohm and Haas Company, Germany) as substrate. In the study, the authors employed dentifrices and toothbrushes different from ours, as well as the toothbrush's cycle on the substrate, velocity of the back and forth movement, and time elapsed for toothbrushing.

Panzeri et al. 12, in 1979, assessed the abrasive rate occurring in plexglass plates by 24 dentifrices associated with "soft" toothbrushes, in a toothbrushing machine Pepsodent. Each plate was evaluated regarding to the weight loss and rugosity variation. The authors found that the dentifrices caused varied wear rates, with the control (water) presenting the lowest one, followed by non-abrasive dentifrices.

On the other hand, Harrington et al. 7, in 1982, evaluated the abrasive wear undergone by two glass ionomer cements – ASPA® (A. D. International Ltda., London, England) and Fuji® type I (GC Corporation, Tokyo, Japan), among 17 restorative materials. Through a machine whose horizontal axis spins at 120 rpm velocity making Oral B-60® toothbrushes perform a horizontal movement on the specimens, the authors found that the thickness loss was 26.1 mm (standard deviation of 2.08) for ASPA® and 27.0 mm (standard deviation of 4.44) for Fuji® type I.

Three years later, De Boer et al. 4 analysed in vitro the dentinal wear caused by four dentifrices whose particles were composed by CaCO3 or Al(OH)3, with mean dimensions ranging from 1 to 15 mm and 8 to 13 mm, respectively. Each toothbrush executed a movement amplitude of 37 mm on the specimen, with load of 200 gf, and machine regulation for performing 1,000, 2,000, 5,000, and 10,000 toothbrushing cycles. An amount of 3 g of each original dentifrice was diluted into 7 ml of water. By verifying the thickness loss of the specimens through a rugosimeter and the mass loss, the authors concluded that the wear rate 1 always was linearly related to the number of cycles. Wear rate 2 was 1.4 times more severe with medium flexibility toothbrushes, regardless the dentifrice used; wear rate 3 was significantly different for all four dentifrices; and wear rate 4 was higher for dentifrices of greater abrasive particles.

Thomassewski et al. 14 examined different glass ionomer cements indicated for ART, through simulated toothbrushing test of 20,000 cycles. Composite resin was used as control.

The report of these few studies aimed to characterize the impossibility of results' comparison.

Our study and the research of Almeida et al. 1 were developed by one single researchers' team, with the same method, and the same toothbrushing machine. The global analysis of the results of the two studies makes us suspect that, as time goes by, an alteration in the load, by which the machine arms' springs pushed the toothbrushes against the specimens, would occur. Therefore, we decided that in further studies, each restorative material and PMMA will be placed at all 10 positions of the machine.

Lambrechts et al. 10, in 2006, concerned about in vitro Dentistry wear simulators capacity of reproducing real conditions, cited 19 aspects that they judged as complicating factors. Among them it can be highlighted the aggressive agent standardization, used load, number of cycles, frequency of contact of the used agents (and their duration), homogeneity of the used material, and the presence of wear fragments.

A similar concern had been already demonstrated, in 1997, by Momoi et al. 11 when they evaluated the wear rate of glass ionomers in a toothbrushing machine, in which each toothbrush exerted a 3.4 N load on the specimen, at 160 cycles/min frequency, up to reach 20,000 cycles. Aluminum hydroxide was used as abrasive. The authors observed a non significant correlation with the clinical results, because different processes, such as abrasion, adhesion, fatigue and erosion interact among each other.

Conclusion

According to the methodology used, it can be concluded that Vidrion R® (mass loss of 52,0 mg) presented a greater wear than ChemFlex® (mass loss of 5.57 mg).

Acknowledges

We thank to the Foundation of Support to Research of Sao Paulo (short FAPESP) for the financial support of this study (BIC 04/07241-4); to PhD, Msc José Roberto Pereira Lauris from the Discipline of Research Methodology and Statistics, Bauru Dental School – USP, for the statistical analysis; and to Colgate®, through PhD, Msc Nilce Emy Tomita from the Discipline of Community Health, Bauru Dental School – USP, for the cession of the toothbrushes used in this study.

This study was carried out at the Discipline of Dental Materials of Bauru Dental School – USP, together with the Department of Mechanical Engineering, Bauru School of Engineering, Sao Paulo State University.

References

1. Almeida CT, Freitas CA, Freitas MFA, Bianchi EC, Imai LJ. Desgaste dos cimentos de ionômero de vidro Vidrion R e ChemFlex, promovido pelos dentifrícios infantis Tandy e Baby Barney em máquina de escovação. Rev Pós-Grad. 2007;14:45-51. [ Links ]

2. American Dental Association. Council on Dental Materials and Devices. American National Standard. Specification n. 66 for dental glass ionomer cements. J Am Dent Assoc. 1989;119(1):205.

3. Cintra MB, Bianchi EC, Freitas MFA, Freitas CA, Aguiar PR, Ulhôa MPM. Abrasive wear of conventional glass ionomer cements. Braz J Biom Eng. 2008;24(1):17-22.

4. De Boer P, Duinkerke ASH, Arends J. Influence of tooth paste particle size and toothbrush stiffness on dentine abrasion in vitro. Caries Res. 1985;19(3):232-9.

5. Fabretti A, Correr Sobrinho L, Sinhoreti MAC, Consani S, Guirado CG... Avaliação in vitro da abrasão produzida por dentifrícios e escovas dentais infantis. RFO. 1997;2(1):33-40.

6. Frencken JE, Holmgren CJ. Tratamento restaurador atraumático (ART) para a cárie dentária. São Paulo: Santos; 2001.

7. Harrington E, Jones PA, Fisher SE, Wilson HJ. Toothbrush: dentifrice abrasion. Br Dent J. 1982;153(4):135-8.

8. International Organization for Standardization. Technical Report ISO/TR n. 14569-1. Dental materials: guidance on testing of wear. Part 1: wear by toothbrushing. Technical Report. Switzerland: International Organization for Standardization; 2007.

9. Kent BE, Lewis BG, Wilson AD. The properties of a glass-ionomer cement. Br Dent J. 1973;135(7):322-6.

10. Lambrechts P, Debels E, Landuyt K, Peumans M, Meerbeek B. How to simulate wear? Overview of existing methods. Dent Mater. 2006;22:693-701.

11. Momoi Y, Hirosaki K, Kohno A, McCabe JF. In vitro toothbrush-dentifrice abrasion of resin-modified glass ionomers. Dent Mater. 1997 Mar;13(2):82-8.

12. Panzeri H, Lara EHG, Siéssere F, Marchetti RM. Avaliação de dentifrícios III: desgaste provocado por escovação in vitro. Odont Moder. 1979;6(2):26-32.

13. Rios D, Honório HM, Araújo PA, Machado MAAM. Wear and superficial roughness of glass ionomer cements used as sealants, after simulated tooth brushing. Pesqui Odontol Bras. 2002;16:343-8.

14. Thomassewski MHD, Santos FA, Wambier DS. Wear of glass ionomer cement indicated atraumatic restorative treatment after simulated toothbrushing. Rev Odontol Unesp. 2009;38(3):135-42.

15. Wilson AD, Kent BE. A new translucent cement for dentistry: the glass ionomer cement. Br Dent J. 1972;132(4):133-5.

16. World Health Organization. Revolutionary new procedure for treating dental caries. Geneva, 1994. [cited 1995 Apr 30]. Available from: URL:http://www.who.int/archives/inf-pr-1994/pr94-28.html.

Correspondence:

Correspondence:

Márcia Furtado Antunes de Freitas

Alameda Dr. Octávio Pinheiro Brisolla, 9-75 – Vila Cidade Universitária

CEP 17012-901 – Bauru – SP – Brasil

E-mail: mfafreitas@usp.br

Received for publication: September 13, 2010

Accepted for publication: January 24, 2011