Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RSBO (Online)

versão On-line ISSN 1984-5685

RSBO (Online) vol.9 no.1 Joinville Jan./Mar. 2012

ORIGINAL RESEARCH ARTICLE

Mechanical and microstructural properties of a nickel-chromium alloy after casting process

André Rocha Pimenta I,II; Marilia Garcia Diniz II; Sidnei Paciornik III;Carlos Antonio Freire Sampaio IV;Mauro Sayão de Miranda IV;José Maria Paolucci-Pimenta I,V

I Department of Mechanics, Federal Institute of Rio de Janeiro – Paracambi – RJ – Brazil.

II Program of Post-Graduation in Mechanics Engineering, University of Rio de Janeiro State – Rio de Janeiro – RJ – Brazil.

III Department of Engineering of Materials, Pontifical Catholic University of Rio de Janeiro – Rio de Janeiro – RJ – Brazil.

IV School of Dentistry, University of Rio de Janeiro State – Rio de Janeiro – RJ – Brazil.

V Department of Welding, Iguaçu University – Nova Iguaçu – RJ – Brazil.

ABSTRACT

Introduction: There is a growing concern on the development of adequate materials to interact with the human body. Several researches have been conducted on the development of biomaterials for dental applications. Objective: This study aimed to determine the microstructural and mechanical properties of a nickel- based alloy, after the casting process. Material and methods: The alloy was melted through lost wax technique and centrifugation, by using blowtorch with liquefied petroleum gas. To evaluate the mechanical properties, tensile bond strength and microhardness tests were performed. The microstructural characterization was performed using scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). Statistical analyses were performed on microhardness results, through Student t test. A program for digital image processing was used to determine the percentage of the existing phases. Results and Conclusion: The tensile strength was higher than that reported by the manufacturer, 559.39±25.63MPa versus 306 MPa, respectively. However, the yield strength was slightly lower, 218.71±29.75 MPa versus 258 MPa, reported by the manufacturer. The microhardness tests showed about 70 HV, far above the value informed by the manufacturer (21 HV). It can be affirmed with 95% confidence interval that the casting process did not alter the material's hardness. The alloy's microstructure is formed by a matrix with dendritic aspect and gray color and a second white interdendritic phase with equally distributed precipitates as well as porosities. EDS tests showed that the matrix is rich in nickel and chromium, the interdendritic second phase is rich in molybdenum and the precipitates in titanium or silicon. The matrix represents 86% of the area and the second phase 12%.

Keywords: nickel; hardness; tensile strength.

Introduction

There has long been a concern to restore the proper functioning of human body parts when they have been adversely affected by either diseases and accidents or weariness due to their use. This concern also comprises both aesthetical 12,24 and functional issues, consequently leading to increasingly detailed studies on materials 17,30 , procedures, and surgical techniques. The materials interacting with a biological system are called biomaterials. Generally, a biomaterial should have high mechanical resistance, resistance to weariness, and mainly biocompatibility, i.e., it does not cause any adverse effect when inserted into the human body 16,23,27,28 . There are a growing number of studies on dental reconstructions. The concern about the development of construction techniques, materials and procedures is justified by the large number of people necessitating these services. The most frequent surgical procedure executed in human beings is tooth extraction 21,23 . The ideal material for dental reconstruction should meet aesthetical and functional requisites, as well as to provide long-term confidence 13 . Metal alloys have been used since ancient times for tooth reconstructions. The Romans, Chinese and Aztecs used gold for this purpose for over 2,000 years ago. Metals provided high mechanical resistance and fracture toughness, being considered ideal for supporting the effort existing during the masticatory process. However, metals are not aesthetically desirable because they cannot mimic natural teeth. In 1962, Dr. Abraham Weinstein obtained two patents to cover gold alloys with porcelain, the technique so-called metal-ceramic restorations 3. This technique enables to combine the metal's good mechanical properties with porcelain's good aesthetical finishing.

Gold-based alloys have showed a long-term successful history for dental restorations and have been considered as gold standard 1,19. Notwithstanding, due to their increasingly cost, they have not been frequently used. Currently, the most used alloys for metal-ceramic crowns are nickel-based alloys 20,26. Nickel alloys were introduced into dental market during the 30s 19 and they present high mechanical resistance and hardness combined to a high fracture toughness and excellent resistance to corrosion 23. The aim of this study was to determine the microstructural and mechanical properties of a nickel-based alloy, employed as a dental biomaterial, after the casting process, identifying its mechanical properties of resistance and hardness as well as the chemical composition of its phases and their percentage in the microstructure. It is expected that this study contribute to the available knowledge on dental alloys, enabling the development of further methodologies to improve these materials' properties.

Material and methods

This study used a nickel-based alloy (FIT CAST-SB Plus, Talladium, Brazil). The chemical composition provided by the manufacturer is 60.75% Ni, 25% Cr, 10% Mo, 2% Si, <1% Ti. This alloy's main feature is the absence of beryllium, an element generally added to nickel alloys to diminish the alloy's casting temperature, despite of its doubtful biocompatibility 22,26.

Four samples were casted in the Dental Prosthesis Laboratory of the School of Dentistry of the University of the Rio de Janeiro State (UERJ) to perform the tensile strength test. These samples were constructed by lost wax technique and centrifugation 3 presenting a cylindrical shape and 2.5 mm diameter and 30 mm length. The cast was constructed with pre-fabricated wax sticks with the aforementioned dimensions.We used a casting investment (Micro Fine 1700) following the manufacturer's instructions to cover the wax sticks on a vacuum dental vibrator to avoid blisters. After 20 minutes, the casting investment was put into a furnace, preheated at 750ºC, with final temperature of 950ºC, without the need of controlling the heating rate, according to the manufacturer's instructions. After 5 minutes, at 950ºC, the die was removed and sent to the casting process. The casting process was executed through blowtorch with liquefied petroleum gas (LPG) and oxygen, at the following pressures: 27.58 to 34.48 kPa (4 to 5 psi) and 172.38 to 206.85 kPa (25 to 30 psi), for LPG and oxygen, respectively. The metal casting was executed in a hand centrifuge for dental casting. After the cast cooling, the investment was removed and the sample was sandblasted with 50 μm aluminum oxide at 551.6 kPa (80 psi) to remove the investment, completely.

For chemical analysis, the tested sample (C) and the material sample received from the manufacturer (CR) were assessed through atomic emission spectrometer (Optima 4300 CV, Perkin Elmer Instruments) to determine the percentages of nickel, chromium, and molybdenum, which are the three main chemical elements in the alloy.

To perform the tensile strength tests of the C samples, a universal testing machine (EMIC, DL 1000) was used at crosshead speed of 2,000 mm/min. This machine automatically determines the tensile strength and the yield point at 0.2% of deformation. The CR sample could not be submitted to bond strength test because its morphology (sticks with 5 mm diameter and 12 mm length) did not allow its placement into the universal testing machine.

After the tensile strength test, the C and CR samples were submitted to the metallographic preparation through sanding and polishing techniques to be analysed by scanning electronic microscopy (SEM) and Vickers microhardness test.

Vickers microhardness test was performed according to ABNT Regulation (NBR NM ISO 6501-7), with load of 0.9807 N for 15 seconds. The tests were executed in a microscope (Neophot 2, Carl Zeiss) supplied with a device for the microhardness test. The mean value of the impression diagonals of the penetrator was converted into Vickers microhardness value, according to the ABNT Regulation (NBR NM ISO 6507-4). Two C samples and one CR sample were submitted to microhardness test with five penetrations in each one.

The null hypothesis tested (H0) by Student t distribution prior to the application of analysis of variance (F distribution test) was executed in the microhardness test results to determine whether there would be or not be a significant variation between the samples. This test enables to affirm whether two groups belong to the same family 8,18. The tests were performed at 95% of bilateral confidence (α = 0.05).

SEM (JSM-6460, JEOL) was used to obtain the sample's microstructure images, at BSE mode, 20 kV, and 80 μA. An energy dispersive spectroscopy (EDS) system attached to SEM was employed to execute the semi-quantitative analysis of the existing chemical elements. Three C samples and one CR samples were submitted to SEM analysis. For each one of the C samples, ten images of random areas were obtained to allow the posterior quantification by the image digital processing (IDP) technique by ImLab software. We determine the ratios of each phase as well as the medium size of each metal grain.

Results

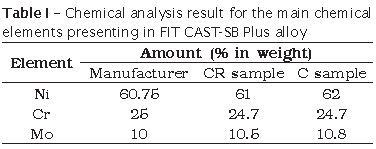

Table I presents the results of the chemical analysis of each material, before and after casting as well as the values supplied by the manufacturer.

The result means of the chemical properties of tensile strength and yield point, for four tested samples analysed in the tensile strength test was 559.39±25.63 MPa and 218.71±29.75 MPa, respectively.

The result means of the Vickers microhardness test obtained for two C samples were 70.28±3.10 HV and 70.99±5.63 HV, and for the CR sample was 72.77±4.78 HV.

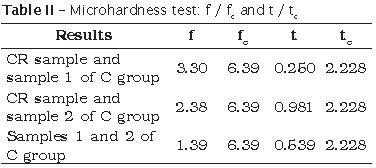

Table II presented the f and t values of F distribution and Student t tests, as well as f and t critical values (fc and tc).

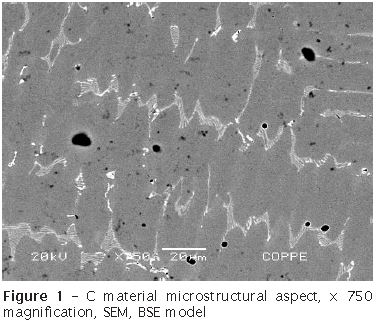

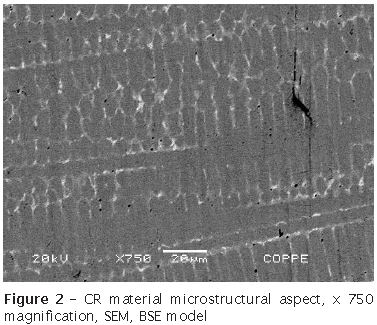

Figure 1 and 2 shows, respectively, the material's microstructural aspect of C and CR sample.

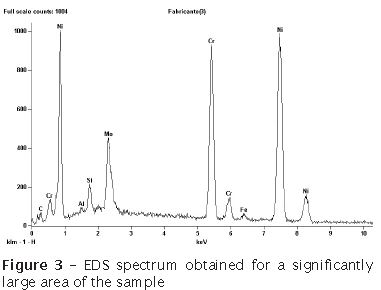

The semi-quantitative chemical analysis performed by EDS technique in a relatively large area of the specimen showed a similar result, regardless of the tested condition (C or CR). Figure 3 shows the EDS spectrum to exemplify these results.

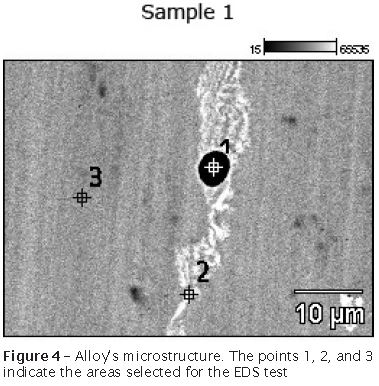

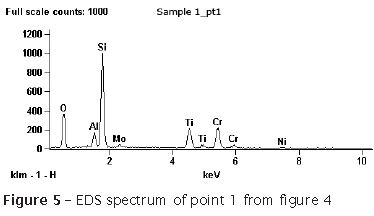

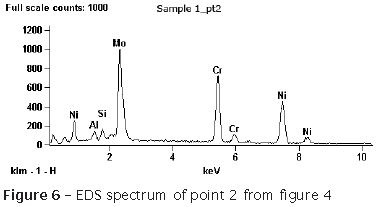

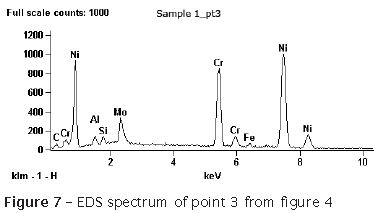

EDS technique was also used to determine the chemical composition of each identified individual phase. Figure 4 exhibits an image of the material's microstructure. The marked points (n=3) indicates the sites were the EDS tests were performed at the selected areas. The points 1, 2, and 3 are marked in figure 4 on the areas of the black, white, and gray phases, respectively. The spectrums obtained from these areas (1, 2, and 3) are shown in figures 5, 6, and 7, respectively.

Similar EDS spectrums were obtained for all points performed at the white and gray areas, regardless of the sample. On the other hand, the black areas varied from silicon (point 1 in figure 4) and titanium precipitates to simply material's porosities. All samples presented the three types of results.

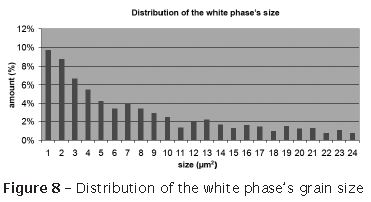

The results obtained from IPD indicated that 86.64% of the microstructure was formed by gray matrix, 12.20% by white second phase, and 1.16% by black areas. Figure 8 displays the distribution of the grains from the white phase for the specimens of C group, through IPD technique.

Discussion

The results from the chemical analysis (table I) indicated that the material's composition is in agreement with that specified by the manufacturer. Considering the analysed elements, it could be observed that there was no variation of the alloy's chemical composition, before and after the casting process.

The bond strength test results indicated that the material presents a tensile strength limit of 559.39±25.63 MPa, greater than the value provided by the manufacturer (306 MPa). However, the yield point value was 218.71±29.75 MPa, slightly lower than the manufacturer's value (258 MPa). It should be noted that the manufacturer does not indicated the metallurgy state of the material and it does not provide data on the manufacturing process used for obtaining the samples, which makes the direct comparison of the results difficult.

In a study comparing an alloy (Tilite Star – 13.5% Cr; 6% Mo; 4% Ti; Bal. Ni; Talladium Inc., Valencia, EUA) with chemical composition similar to that of our study, the authors found a higher mechanical tensile strength value (1050±74 MPa) for the material casted through the same technique used in this study 6. One of the possible hypotheses for this occurrence is that the alloy has a large amount of titanium, which tends to form high-hardness carbide, increasing the material's mechanical resistance 19. It is also known that variations in the alloy's chemical composition provided by the manufacturer may generate this type of difference 11,25.

Although the Vickers hardness values are not presented, the manufacturer makes them available for our study. To convert HV to MPa values, it is necessary to multiply the result by 9.807 15. Therefore, the manufacturer's hardness value is 20.70 HV, a value very lower than those obtained by our study (70 HV). Despite the fact that this study's values are above those informed by the manufacturer, it should be emphasized that the metallurgy state and the manufacturing process of the material used by the manufacturer were not provided. It is known that such parameters can strongly affect the material's mechanical properties 4,9.

As seen in table II, f values are smaller than fc values. Therefore, it can be affirmed that the groups present the same variance, allowing the application of the Student t test. The results of the hypothesis test revealed a reliability of 95% that the null hypothesis was accepted. Consequently,there was no variation between the results of the microhardness test between C and CR groups.

SEM instead of optical microscopy was chosen to perform the microstructural characterization due to the method's simplicity, which did not require chemical attacks that would be necessary to the microstructural observation in the optical system. There is a proven difficulty in finding efficient chemical attacks to reveal clearly the dental nickel alloys' microstructure 14.

By observing figures 1 and 2, one can note that the alloy has a dendritic structure (typically obtained in casting pieces) for the gray phase, a second white interdendritic phase, and black precipitates as well as the presence of porosities. The casting process did not alter the material's dendritic geometry; however, it increased the dendrites' mean size. It is known that the material's grains size can alter its properties, mainly the mechanical resistance, in a way that the lesser the grains the greater the resistance. Notwithstanding, the material here studied probably did not exhibit an increase in the mechanical resistance because the latter is directly proportional to the hardness which did not increase after the casting process, according to the hypothesis tested.

By examining the microstructure of a dental nickel-based alloy, so-called Matchmate (62.2% Ni; 25% Cr; 9,5% Mo; 3.3% Si; Davis Schottlander and Davis, Herts, UK), some authors found a microstructural aspect very similar to that of our study 29. Some authors, in another study in which they examined the microstructure of the dental nickel-chromium alloys Cast-V (14% Cr; 8.5% Mo; 1.8% Be; 1.7% Al; Bal. Ni; Talladium Inc., Valencia, EUA) and Tilite Star, found a structure composed by a gray matrix (dendritic) and a second lace-like phase (interdendritic) for both alloys. The presence of precipitates in the Tilite Star alloy which has titanium in its composition was highlighted by the authors 15. Another study also obtained a similar microstructure when characterizing the NP XIII (76.5% Ni; 14% Cr; 4.5% Mo; 2.5% Al; 1.6% Be; 0.5% Co; 0.4% Ti; Nobilium, Albany, NY) 14.

The EDS spectrums executed in large areas of the samples (figure 3) indicated the significant, already expected presence of nickel, chromium, molybdenum, and silicon. Iron and aluminum was seen in little intensity. From these aforementioned elements, only iron and aluminum were not mentioned by the manufacturer. Therefore, they may be classified as contaminants. It should be noted that the presence of these elements is not associated to any contamination during the casting process, once the sample provide by the manufacturer also contained aluminum and iron peaks in its spectrum.

When aluminum is added to nickel-based alloys, it tends to combine with nickel, forming well-arranged phases which necessitate of large magnifications (about 10,000 times) to be observed. Therefore, these phases would not appear in the micrographs obtained by this study 7.

Also through EDS technique, the chemical composition of Tilite Star alloy was analysed by other researchers. Although the manufacturer does not indicate the aluminum presence, the results obtained by the study indicated that the alloy contained aluminum in its composition 5.

When EDS was used to determine the chemical composition of each phase, individually, it was observed that the gray phase is mainly composed by nickel and chromium, containing low levels of molybdenum (figure 6). The interdendritic phase (white) is rich in molybdenum (figure 5). The black points could be precipitates rich in titanium, silicon, or only porosity within the material.

It is known the titanium tendency towards forming precipitates, generally as carbides. In alloys containing titanium, some studies indicated the presence of precipitates; however, their types were not identified 5,14.

Other authors, by analyzing the chemical composition range existing along the Matchmat alloy's microstructure (with a chemical composition similar to this study's alloy), found a matrix rich in nickel and chromium, in addition to a second interdendritic phase rich in molybdenum and silicon. The microstructure showed in the study showed the presence of precipitates, however the authors did not investigated their type 29.

We did not find studies in literature quantifying the percentage of each phase of the dental nickel alloy. However, it was not possible to compare our results to the studies already published. IPD allows determining precisely the amount and size of each area of the image. The software is capable of counting each pixel of the chosen area through the difference of shades existing among them, obtaining an accurate result 2,10.

Through IPD, it was possible to determine the amount of each phase within the alloy after the casting process (86.64% of gray phase; 12.20% of white phase; and 1.16% of black areas, as previously mentioned). Because all black areas have the same shade, it was not possible to determine the amount of porosity, titanium and silicon precipitates, independently. The second white phase's grains were, generally, of small size, presenting mostly, up to 10 μm²

Conclusion

The casting process, when executed according to the manufacturer's instructions, did not alter the alloy's chemical composition.

This study's alloy presented, after the casting process, a tensile strength limit of 559.39±25.63 MPa higher than that informed by the manufacturer; a yield point of 218.71±29.75 MPa, slightly lower than that informed by the manufacturer.

The microhardness value found was 70.28±3.10 HV and 70.99±5.63 HV, for the C samples, and 72.77±4.78 HV for the CR sample, values well above of 20.70 HV provided by the manufacturer. It can be affirmed with 95% of reliability that the casting process did not modify the alloy hardness.

The alloy microstructure is formed by a gray matrix of dendritic structure, a second interdendritic white phase of lace aspect and black precipitates, in addition to porosities. These shade differences allowed the use of analysis and digital processing techniques for the accurate quantification of the present phases. The matrix is rich in nickel and chromium, the interdendritic phase in molybdenum and the precipitates are rich in silicon or titanium.

The material's microstructure provided by the manufacturer has an interdendritic phase mean size smaller than that of the casted alloy (qualitative analysis).

References

1. American Dental Association. Guide to dental materials and devices specification n. 5 for dental casting gold alloy. Chicago: American Dental Association; 1972. [ Links ]

2. American Society for Metals. Handbook metallography and microstructures. Ohio: American Society for Metals; 2004.

3. Asgar K. Casting metals in dentistry past present future. Adv Dent Res. 1988 Aug;2(1):33-43.

4. Askeland DR, Phulé PP. The science and engineering of materials. Florence: Cengage Learning; 2008.

5. Bauer JRO, Loguercio AD, Reis A, Rodrigues LE. Microhardness of Ni-Cr alloys under different casting conditions. Braz Oral Res. 2006 Mar;20(1):40-6.

6. 6. Bauer JRO, Reis A, Loguercio AD, Rodrigues LE. Resistência à tração e alongamento de ligas de Ni-Cr fundidas sob diferentes condições. RPG Rev Pós-Grad. 2006;13(1):83-8.

7. Brooks CR. Heat treatment structure and properties of nonferrous alloys. Ohio: American Society for Metals; 1982.

8. Bussab WO, Morettin PA. Estatística básica. 5. ed. São Paulo: Saraiva; 2005.

9. Callister WD. Materials science and engineering an introduction. 7. ed. Danvers: John Wiley & Sons; 2007.

10. Gonzalez RC, Woods RE. Digital image processing. 3. ed. New Jersey: Pearson Education; 2008.

11. Huang HH. Effect of chemical composition on the corrosion behavior of Ni-Cr-Mo dental casting alloys. J Biomed Mater Res A. 2002;60(3):458-65.

12. Hoppen LRC, Garbin CA, Rigo L, Schuh C, Federizzi L. Comparação estética entre coroas confeccionadas com os sistemas cubo e metalocerâmico. RSBO. 2010 Jun;7(2):146-53.

13. Kelly JR. Clinically relevant approach to failure testing of all-ceramic restorations. J Prosthet Dent. 1999 Jun;81(6):652-61.

14. Lin HY, Bowers B, Wolan JT, Cai Z, Bumgardner JD. Metallurgical surface and corrosion analysis of Ni-Cr dental casting alloys before and after porcelain firing. Dent Mater. 2008 Mar;24(3):378-85.

15. Malishev A, Nikolaiev G, Shuvalov T. Tecnologia dos metais. 1. ed. São Paulo: Mestre Jou; 1970.

16. Manaranche C, Hornberger H. A proposal for the classification of dental alloys according to their resistance to corrosion. Dent Mater. 2007 Nov;23(11):1428-37.

17. Menon LML, Prado KFB, Silva RHA. Avaliação histológica da dentina e do cemento após diferentes tempos de inumação: estudo in vitro. RSBO. 2011 Apr-Jun;8(2):131-7.

18. Montgomery DG. Design and analysis of experiments. 5. ed. New York: John Wiley and Sons; 2001.

19. Morris HF, Manz M, Stoffer W, Weir D. Casting alloys the materials and the clinical effects. Adv Dent Res. 1992 Sep;6:28-31.

20. Olivieri KAN, Neisser MP, Souza PCR, Bottino MA. Mechanical properties and micro structural analysis of a NiCr alloy cast under different temperatures. Braz J Oral Sci. 2004;3:414-9.

21. Park JB. The biomedical engineering handbook. Boca Raton: CRC Press; 2000.

22. Pellizzer AJ, Bombonatti PE, Valerio WV. Fluidez de liga de níquel-cromo de procedência nacional ação da elevação da temperatura de estufagem dos revestimentos fosfatados. Rev Odontol Unesp. 1995;24(1):99-107.

23. Ratner BD, Hoffman AS, Schoen FJ, Lemons JE. Biomaterials science an introduction to materials in medicine. San Diego: Academic Press; 1996.

24. Rossato DM, Saade EG, Saad JRC, Porto-Neto ST. Coroas estéticas anteriores em cerâmica metal-free: relato de caso clínico. RSBO. 2010 Oct-Dec;7(4):494-8.

25. Vergani CE, Leonardi P, Cucci ALM, Giampaolo ET. Análise qualitativa de ligas metálicas para próteses parciais removíveis. Rev Odontol Unesp. 1994;23(2):297-305.

26. Wassell RW, Walls AWG, Steele JG. Crowns and extra-coronal restorations materials selection. Br Dent J. 2002 Feb;192(4):199-211.

27. Wataha JC. Alloys for prosthodontic restorations. J Prosthet Dent. 2002 Apr;87(4):351-63.

28. Wise DL. Biomaterials and bioengineering handbook. Boca Roton: CRC Press LLC; 2000.

29. Wylie CM, Shelton RM, Fleming GJP, Davenport AJ. Corrosion of nickel-based dental casting alloys. Dent Mater. 2007 Jun;23(6):714-23.

30. Zielak JC, Locatelli P, Pozzan S, Giovanini AF, Deliberador TM, Urban CA et al. Avaliação ultraestrutural comparativa de biomaterial particulado de origem ovina. RSBO. 2011 Jan-Mar;8(1):40-7.

Correspondence:

Correspondence:

André Rocha Pimenta

Rua Sebastião Lacerda, s/n.°

CEP 26600-000 – Paracambi – RJ – Brasil

E-mail: rochapimenta@gmail.com

Received for publication: January 31, 2011

Accepted for publication: June 22, 2011