Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RSBO (Online)

versão On-line ISSN 1984-5685

RSBO (Online) vol.10 no.2 Joinville Abr./Jun. 2013

ORIGINAL RESEARCH ARTICLE

Comparative evaluation of the accuracy of pick up transfer impressions performed with two different types of trays

Aline TremlI; Gustavo Holtz GalvãoI; Allan Fernando GiovaniniI; Eduardo Christiano Caregnatto de MoraisI; Carla Castiglia GonzagaI; Enio Marcos da SilvaI

I Master of the Science Program in Clinical Dentistry, Positivo University – Curitiba – PR – Brazil.

ABSTRACT

Introduction: The success of implant-supported prostheses is related to the passive union between the prostheses’ connections and the implants, so it is necessary to obtain an accurate working cast.

Objective: To evaluate the accuracy of the transfer impressions of implants performed with individual acrylic resin trays and conventional trays using polyvinyl siloxane.

Material and methods: To carry out the transfer impressions, a master cast with four external hexagon implants parallel to each other was used. Five impressions were made with individual acrylic resin trays and five other impressions with modified conventional trays, opened in the region of the implants. The linear measurements between the implants were made with a digital caliper with an accuracy of 0.01 mm and the results were statistically evaluated (alpha = %).

Results: For the points AB and BC, the measurements obtained with the individual trays were statistically similar to the master cast. For the points CD and DA no statistical differences among the three groups were observed.

Conclusion: Given the obtained results and the methodology used, it can be concluded that the impressions performed with individual trays presented higher accuracy compared to the ones obtained with conventional trays.

Keywords: dental implants; dental impression technique; dental casts.

Introduction

The osseointegrated implants have been used for the rehabilitation of edentulous patients aiming to replace conventional complete dentures3,13,22. The success of implant-supported prostheses is directly related to the passive union between the prostheses’ connections and the implants themselves. Thus, it is necessary to obtain a cast reliable to the positioning of the implants in oral cavity and on which the most adequate transfer technique of the prosthetic abutments is performed5,20.

The transfer impression for osseointegrated implant aims to record, transfer and reproduce with certain accuracy the relationship between the implants and the surrounding structures through the connection of transfer copings to the abutments installed24. Next, to obtain the working cast, the implant analogues or replica are connected to the mucosal transfer copings10. To achieve the properly adaptation of the prosthesis, an accurate impression must be executed to prevent either mechanical or biological failures. Mechanical failures would comprise the maladjustment of the prosthesis, loosening or fracture of the screw, fracture of the implant and incorrect occlusion11. On the other hand, the biological failures may be related to soft tissue irritation, pain, marginal bone loss and osseointegration loss6. Concerning to the conventional impression techniques of fixed dentures, the transfer impression of the implants can present a relative easy execution, once devices for gingival tissue retraction as impression caps and retraction threads are not required.

For the impression of the abutments of implant-supported prostheses, either for multiple or single cases, two main techniques are employed: impression technique with the aid of conventional trays (closed trays), in which transfer copings without retention are used; and the impression technique with the aid of customized trays (open trays) in which a customized acrylic resin tray is perforated and trimmed at the implant area, with the aid of transfer copings with retention9,18.

When employing the closed trays, the dentist should use cone-shaped transfer copings, which are kept in the mouth after the impression is removed and then replaced onto the impression to construct the artificial gingiva and pour the stone18. This type enables that the replica could be screwed outside the impression to obtain a better visualization of the adaptation between the two components21. Notwithstanding it may cause distortions in the impression material at the moment of its removal because the greater the discordance2,16 and the contact among the abutments16, the greater the inaccuracy of the impression.

For the transfers with opened trays, square transfer copings are used, which need the union with the aid of dental floss and acrylic resin inside the mouth. These transfers correspond to the perforations of the trays and they are directly removed together with the impression, therefore receiving the application of the artificial gingiva to construct the working cast18. As advantages of the use of the opened tray, it can be cited the minimum error rate and the fact of working from the beginning to the ending on the same cast; as disadvantages: the high cost of the customized tray and one more appointment for the procedures20.

The conventional plastic tray is very used in daily clinical practice, therefore avoiding the execution of a previous impression with irreversible hydrocolloid and the construction of a customized acrylic resin tray. However, in literature, there are not studies demonstrating the application of these trays in the technique with square transfers in comparison with the customized trays.

The immobilization of transfer copings (square), together with an intraoral pre-fabricated self-cured acrylic resin bar has shown better results when one desires a certain accuracy in the impression5,9,12,17. Theoretically, this splinting technique is performed to prevent the displacement of the copings during the impression12.

Among the several impression materials to be utilized in the transfer of implants, polyether and addition silicone have been the most indicated2,8,15,24, because they show a greater dimensional stability, greater hardness and elastic recovery2,8,15.

Addition silicone, because of its excellent physical properties, has a privileged post among the impression materials. Its introduction in the market caused a restriction in the use of condensation silicone which because of the elimination of a sub-product – ethanol – results in unreliable impressions with the need of the immediate pouring of the plaster15,23. During the obtainment of the working cast, this material enables accuracy in the reproduction of small details, mainly at the cervical area, in addition to its dimensional stability and easier visualization of the cervical margins15,19.

Thus, the aim of this study was to evaluate the accuracy of the transfer impressions of implants performed with individual acrylic resin trays and conventional trays using polyvinyl siloxane.

Material and methods

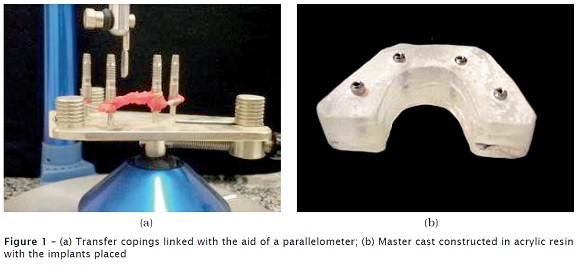

Four implants (4.1 x 13 mm) with hexagon platform (Osteofit, Dental Special Produtos Industriais Ltda., Campo Largo, PR, Brazil) were parallely fixed with the aid of a parallelometer and the transfer copings were linked through dental floss and red acrylic resin (figure 1a). The implants were then placed onto a pre-fabricated rubber mold with the shape of a dental arch and fixed with addition silicone (Stern Tek, Sterngold, Germany). After the setting of this material, to construct the master cast, a colorless acrylic resin (Jet Clássico, Artigos Odontológicos Clássico Ltda., São Paulo, SP, Brazil) was used to simulate the installation of the implants to construct the protocol prosthesis (figure 1b).

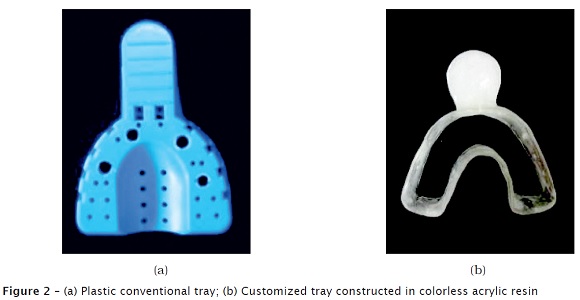

The impressions were performed with plastic conventional trays (Tray Aways, Harry J. Bosworth Company, Skokie, IL, USA) and customized acrylic resin trays (figure 2). The conventional trays were relieved at the implant areas with the use of a tungsten carbide bur. To construct the customized trays a copy of the master cast was obtained. The master cast was relieved with two dental wax laminas number 7 (Artigos Odontológicos Clássico Ltda., São Paulo, SP, Brazil) and retentions were made onto its lateral sides to assure a space for the impression material. This model was then impressed with an irreversible hydrocolloid (Cavex, Color Change, Cavex, Haarlem, Holand), and the cast was poured with type IV stone (Durone IV, Dentsply, Rio de Janeiro, RJ, Brazil). This model was used to construct customized colorless self-cured acrylic resin trays.

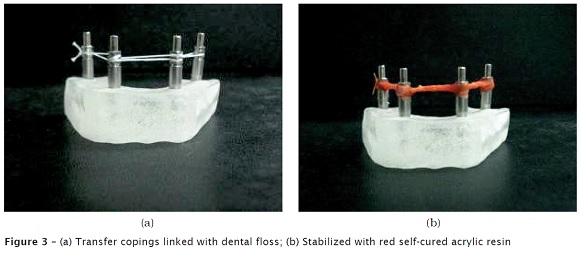

Impression copings for open tray (square copings) for external hexagon, of 4.1 mm diameter, were used and linked with dental floss and self-cured acrylic resin (Pattern, Harry J. Bosworth Company, Skokie, IL, USA) (figure 3).

The heavy and light addition silicone (Elite HD+, Zhermack SpA, Rovigo, Italy) was distributed and handled according to the manufacturer’s recommendations, by executing a single-step impression. The tray was placed by applying a digital pressure. After the impression material setting, the impression was separated from the master cast.

The analogues were placed onto the transfer copings to obtain working casts by pouring type IV stone (Durone IV, Dentsply, Rio de Janeiro, RJ, Brazil), mixed and handling according to the manufacturer’s recommendations, under constant vibration. After two hours, the impressions were separated from the casts.

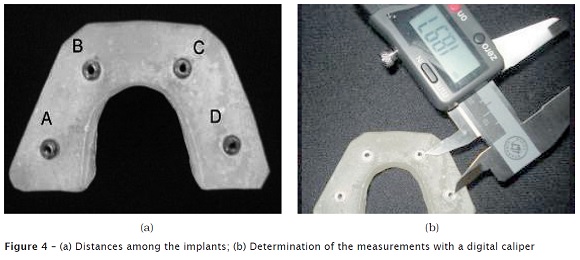

Then, the linear measurements of all distances among the implants were established (figure 4) through a digital caliper (Starrett, Itu, SP, Brazil) with accuracy of 0.01 mm. For each condition, five casts were obtained and for each one three measurements were executed.

The values obtained in the casts were compared with the measurement of the master cast and the results were statistically evaluated through the analysis of variance and Tukey’s test, with level of significance of 5%.

Results

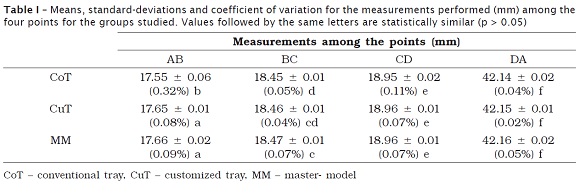

The results for the distances measured among the four implants are seen in table I. For the points AB and BC, the measurements obtained with the customized trays were statistically similar to the master cast. For the points CD and DA there was not statistically significant difference among the three groups.

Discussion

The hypothesis to be test in this study was that there would not be difference in the accuracy of the casts obtained from impressions through conventional or customized trays. However, this hypothesis was rejected, once, for two measurements analyzed, the customized tray was more accurate than the conventional tray.

The most used impression techniques are the close tray/cone-shaped transfer copings and open tray/square transfer copings, which may or may not be linked11. Notwithstanding, the literature has reported that when acrylic resin is used to link transfer copings, the cast is more accurate1. The impressions utilized in this study were through open acrylic resin customized trays and conventional trays with square transfer coping linked through dental floss and self-cured acrylic resin. The master cast was constructed in the shape of a dental arch to the best approximation with the clinical reality and poured with acrylic resin to avoid any deformation in the casts obtained from them. A digital caliper was used to measure the distances among the implants, because this device allowed a precise reading between the extension of the points of choice and also makes the reading easier for the examiner. To perform the measurements, the points of choice must be fixed and stable in all casts and the force applied onto them must be minimum. Aiming to obtain a precise mean of these distances, three measurements for each cast was executed.

In the analysis of the results, it could be observed a statistically significant difference at the points AB and BC for the groups of conventional trays (CoT). However, the literature reports studies with similar methodologies in which the comparison of the accuracy of three different impression techniques that there was not difference among groups11,21. It should be highlighted that it was not found studies that had conducted the same study design, using the same impression technique and only varying the tray. In this present study, it could be said that the dimensional alteration in points AB and BC could have occurred by some motives, such as: the use of a modified conventional tray, relatively small number of samples (n = 5), lack of control during the force application at the moment of the mensuration or even because the measurements were not executed exactly at the same point of choice.

Concerning to the impression technique, the literature does not have a consensus. Some authors indicate that the utilization of square transfer copings in the direct technique tend to exhibit a greater dimensional accuracy regarding to the cone-shaped transfer copings3,7,12,17. However, Humphires et al.14 reported that the impression techniques with square transfer copings linked to acrylic resin showed greater accuracy regarding to the impression techniques with cone-shaped transfer copings. On the other hand, Carr7 and Pinto et al.21 did not observe differences regarding the accuracy of the pick-up impression technique in relation to the transfer impression technique. The use of cone-shaped transfer coping provides that the analogue could be screwed outside the impression, therefore allowing a better visualization of the adaptation between the two components21. According to Michalakis et al.16, the impression material distortion could occur in this impression type during the removal, which results in its permanent deformation because the greater the divergence among the analogues and the proximity of the abutments, the greater the impression inaccuracy. Because these reasons, in this present study, the use of impressions with open trays was opted because the possibility of a correct positioning of the implant is greater due to the fact that the transfer coping be removed with the impression, by avoiding the positioning stage and its insertion within the impression, which may result in displacement20.

The impressions executed with customized and modified conventional trays showed a statistically significant difference, since when the customized tray is used the study cast was considered more accurate when compared to the master cast. According to Burns et al.4, this difference was also observed because in their study with three different types of open trays (conventional polycarbonate tray, customized rigid tray with relief, and customized rigid tray without relief) the customized rigid tray with relief exhibited the most accurate casts and it was not seen statistically significant differences between the other two types of customized trays.

The literature reports that conventional trays did not provide an accurate adjustment since the material thickness is not homogenous; also some trays are not flexible. Notwithstanding, the customized trays are rigid and more stable and allowed a homogenous thickness of the material and consequently more accurate casts8.

In addition to the tray type to be used in the impression of the implants, the material is also of fundamental importance to enable a passive seating for the prosthesis. In a study conducted to evaluate the morpho-dimensional behavior of the materials, six addition silicones, one polyether, one polysulphate, one condensation silicone, and one irreversible hydrocolloid were related and employed in an impression technique of the transfer of the dental implants. In the analysis of the data obtained, the study demonstrated that all materials tested showed statistically significant dimensional alterations. The addition silicones exhibited a smaller dimensional alteration while the irreversible hydrocolloid showed the greatest alteration. All addition silicones produced similar casts, followed by polyether, polysulphate, condensation silicone and irreversible hydrocolloid25.

Finally, it should be remembered that during the conduction of the clinical procedures, such as the transfer impression for implant-supported prostheses, the dentist should not only chose the technique, the impression and cast material, but also have the knowledge on the “pros” and “cons” of the materials and techniques attempting to minimize the undesirable errors and enable a more satisfactory final outcome.

Conclusion

Within the limits of this present study, it can be concluded that the pick up impression technique for the transfer of implants with customized trays was more accurate than that executed with conventional trays at determined measurement points.

Acknowledgements

The authors thank the companies DSP Biomedical, Labordental and Dental News (Bosworth Company) for donating the materials for the execution of the study.

References

1. Assif D, Marshak B, Nissan J. A modified impression technique for implant-supported restoration. J Prosthet Dent. 1994 Jun;71(6):589-91. [ Links ]

2. Assunção WG, Gennari Filho H, Zaniqueli O. Evaluation of transfer impressions for osseointegrated implants at various angulations. Implant Dent. 2004 Dec;13(4):358-66. [ Links ]

3. Assunção WG, Cardoso A, Gomes EA, Tabata LF, Santos PH. Accuracy of impression techniques for implants. Part 1 – Influence of transfer copings surface abrasion. Journal of Prosthodontics. 2008 Dec;17(8):641-7.

4. Burns J, Palmer R, Howe L, Wilson R. Accuracy of open tray implant impression: an in vitro comparison of stock versus custom trays. The Journal of Prosthetic Dentistry. 2003 March;3(89):250-5. [ Links ]

5. Cabral LM, Guedes CG. Comparative analysis of 4 impression techniques for implants. Implant Dentistry. 2007 Jun;16(2):187-94. [ Links ]

6. Campi Junior L, Nagem Filho H, Fares NH, Missaka R, Fiuza CT, D’Azevedo MTFS. Passividade da prótese sobre implante. Innov Implant J. 2010 Sep/Dec;5(3):53-9.

7. Carr AB. A comparison of impression techniques for a five-implant mandibular model. Int J Oral Maxillofac Implants. 1991;6:448-55. [ Links ]

8. Cristensen GJ. Implant prosthodontics contribute to restorative dentistry. J Am Dent Assoc. 1990 Nov;121(5):582. [ Links ]

9. Del’Acqua MA, Chávez AM, Compagnoni MA, Mollo Jr FA. Accuracy of impression techniques for an implant-supported prothesis. The Internacional Journal of Oral and Maxillofacial Implants. 2010 Oct;4(25):715-21.

10. Dinato JC, Polido WD. Implantes osseointegrados: cirurgia e prótese. São Paulo: Artes Médicas; 2001. [ Links ]

11. Faria JCB, Concília LRS, Neves ACC, Miranda ME, Teixeira ML. Evaluation of the accuracy of different transfer impression techniques for multiple implants. Braz Oral Res. 2011 Mar/Apr;25(2):163-7. [ Links ]

12. Gennari Filho H, Mazaro JVQ, Vedovatto E, Assunção WG, Santos PH. Accuracy of impression techniques for implants. Part 2 – Comparison of splinting technique. Journal of Prosthodontics. 2009 Feb;18(2):172-6.

13. Goiato MC, Gennari Filho H, Fajardo RS, Assunção WG, Dekon SFC. Comparação entre três materiais de moldagem e três técnicas de moldagem de transferência para implantes. Revista Cir Implantodont. 2002 Apr/Jun;9(34):164-8. [ Links ]

14. Humphries RM, Yaman P, Bloem TJ. The accuracy of implant master casts constructed from transfer impressions. Int J Oral Maxillofac Implants. 1990;5:331-6. [ Links ]

15. Lorenzoni M, Pertl C, Penkner K, Polansky R, Sedaj B, Wegscheider WA. Comparison of the transfer precision of three different impression material in combination with transfer caps for the Frialit-2 system. J Oral Rehabil. 2000;27:629-38. [ Links ]

16. Michalakis KX, Kalpidis CD, Kang K, Hirayama H. A simple impression technique for dental implants placed in close proximity or adverse angulations. J Prosthet Dent St Louis. 2005 Oct;94(3):293-5. [ Links ]

17. Naconecy MM, Teixeira ER, Shinkai RS, Frasca LC, Cervieri A. Evaluation of the accuracy of 3 transfer techniques for implant-supported prostheses with multiple abutments. Int J Oral Maxillofac Implants. 2004 Mar/Apr;19(2):192-8. [ Links ]

18. Neves FD, Fernandes Neto AJ, Oliveira MRS, Lima JHF, Galbiatti MAD. Seleção de intermediários para implantes Branemark compatíveis parte II: casos de implantes individuais. Rev Bras Implantodont e Prótese Implant. 2000 Apr/Jun;7(26):76-87. [ Links ]

19. Nishioka RS, Almeida EES, Andreatta Filho OD, Balducci I. Avaliação da alteração dimencional entre um silicone de polimerização por adição e outros por condensação. Rev Odontol. 2000 Jan/Dec;29(1/2)93-104. [ Links ]

20. Pieralini ARF, Lazarin AA, Segalla JCM, Silva RHBT, Pinelli LAP. Técnica de moldagem para implantes. Salusvita. 2007 Jan;27(2):169-78. [ Links ]

21. Pinto JHN, Valle AL, Scolaro JM, Bonfante G, Pegoraro LF. Estudo comparativo entre técnicas de moldagem para implantes odontológicos. Rev Fac Odontol. 2001 Jul/Dec;9(3/4)167-72. [ Links ]

22. Prithviraj DR, Pujari ML, Garg P, Shruthi DP. Accuracy of the implant impression obtained from different impression materials and techniques: review. Journal section: Clinical and Experimental Dentistry. 2011 Dec;3(2)106-11. [ Links ]

23. Rode SM, Dutra CR, Matson E. Controle clínico da alteração dimensional dos elastômeros. Rev Assoc Paul Cir Dent. 1987 Sep/Oct;41(5):266-9. [ Links ]

24. Silva MM, Mima EGO, Del’Acqua MA, Segalla JCM, Silva RHBT, Pinelli LAP. Técnicas de moldagem em prótese sobre implantes. Revista de Odontologia da UNESP. 2008 May;37(4):301-8.

25. Valle AL, Coelho AB, Scolaro JM. Avaliação do comportamento morfodimensional de materiais de moldagem utilizados em implantes dentais. Rev Fac Odontol Bauru. 2001 Jan/Jun;9(1/2):41-8. [ Links ]

Corresponding author:

Corresponding author:

Carla Castiglia Gonzaga

Universidade Positivo

Rua Professor Pedro Viriato Parigot de Souza, n. 5.300 – Campo Comprido

CEP 81280-330 – Curitiba – PR – Brasil

E-mail: carlacgonzaga@gmail.com

Received for publication: September 12, 2012

Accepted for publication: December 12, 2012