Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RSBO (Online)

versão On-line ISSN 1984-5685

RSBO (Online) vol.12 no.1 Joinville Jan./Mar. 2015

Original Research Article

Linear setting expansion of different gypsum products

César Antunes de FreitasI; Tatiana Sanches ZanottiII; Fabio Antonio Piola RizzanteI; Adilson Yoshio FuruseI; Márcia Furtado Antunes de FreitasIII

I Department of Operative Dentistry, Endodontics and Dental Materials, Bauru School of Dentistry, University of São Paulo – Bauru – SP – Brazil

II Private practice – São Carlos – SP – Brazil

III Department of Dentistry, Regional Integrated University of High Uruguay and Missions – Erechim – RS – Brazil

ABSTRACT

Introduction:Stone casts are used in dentistry to allow the confection of indirect restorations. Thus, gypsum dimensional stability is fundamental in order to achieve a precise fit between dental structure and restorative material.Objective: The purpose of the present study was to evaluate the hygroscopic linear expansion of commercially available gypsum products. Material and methods: Fifteen dental stones were analyzed (4 type II, 5 type III, 4 type IV and 2 type V), with n = 5. One hundred grams of each gypsum product were mixed following the respective manufacturers' recommendations for powder/water ratio and poured into a V-shape mold, connected to an expansion-measuring device. The hygroscopic expansion was evaluated during 120 min and the collected data was converted into percentage and compared to initial dimensions of the specimen. Results: All type II and V dental stones showed expansion values compatible to the ADA and ISO recommendations. Considering type III stones, only Rutenium 3 was compatible with the recommendations. For type IV, only Durone IV showed expansion values higher than that recommended by ADA, but lower than that of ISO recommendations.Conclusion: The hygroscopic linear expansion of gypsum products should be periodically controlled in order to ensure their precision and reliability to dental practice.

Keywords: calcium sulfate; models, anatomic; dental impression materials.

Introduction

In dentistry, in traditional indirect restoration methods, derivatives of gypsum are used, also known as calcium sulfate dihydrate. The manufacturer calcines the dihydrate, transforming it into calcium sulfate hemihydrate which is gypsum itself. After mixing the water with gypsum powder the inverse reaction occurs, so that the gypsum returns to the state of gypsite, after the centered crystal needles growth, forming the spherulites. This growth results in the so called linear setting expansion, as pointed out by several authors6,7,12.

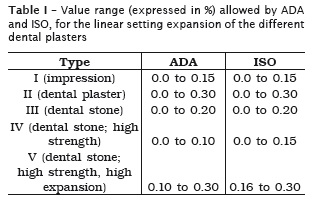

In the Specification n. 25 (since 1972) of the American Dental Association (ADA)1, and in the similar Specification of the International Organization for Standardization (ISO)5, dental gypsum can be classified into five types, each one will determine their application:

I – Impression plaster;

II – Dental plaster;

III – Dental stone;

IV – Dental stone (high strength);

V – Dental stone (high strength, high expansion).

Among many dental applications, gypsum is used for making casts on which various types of prosthetic pieces can be constructed. In the specification of each one of the aforementioned associations, for each type of gypsum is clearly established a range of values allowed for the linear setting expansion, expressed as a percentage, as is briefly illustrated in table I.

Inadequate properties of a plaster can harm the performance of the model with which it is made, and may affect the final quality of the restorative process. Thus, there is great concern about the procedures required to obtain the corresponding plaster model10.

The accuracy of a plaster model depends on a number of factors, such as impression technique, the molding material used therein, the type of gypsum used to obtain the model and its storage form11. Thus, it is important the study not only of the impression accuracy, but also the quality of dental casts available to fit the models2.

It is therefore justified the need for studying the large number (of different types) of plaster on the market so that there is always a quality control, ensuring minor mistakes during the planning and the preparation of prosthetic pieces. The aim of this study was to evaluate the normal setting expansion of existing plaster in local market (between which there is no type I), to verify whether the information from the manufacturers correspond to the real value and also if there is compliance with the relevant Specifications from both ADA and ISO.

Material and methods

All experimental phase of this study was conducted in environmental temperature between 20 to 25ºC and relative air humidity of 50 (±10)%, as required by ADA1 and ISO5.

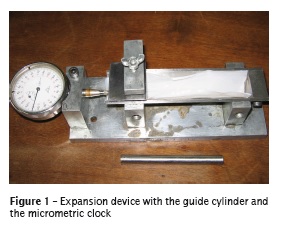

Both Specifications demand the use of a device so-called extensometer, composed of a base supporting a channel made of not informed materials (in this case stainless steel was used), but whose two inclined walls should form an angle of 90 degrees between them; each wall should display internal width of 30±1 mm and length of 25±1 mm. Each channel should be covered by polytetrafluoroethylene (PTFE) sheet, with thickness ranging from 0.1 to 0.2 mm; the channel should still be closed in one of the sides by a fixed piece; the free ending is fixed onto a mobile block (stainless steel with 200±10 g of mass). The distance of the fixed piece from the mobile block should be 100±0.1 mm, which is so called measuring length. A micrometer should be used (also known as display clock, or micrometer clock, or dial gauge), whose action load cannot be greater than 0.8 N, also fixed onto the base. Proper isolating agent (such as Vaseline) should also be applied internally on the channel and mobile block (parts in touch with the plaster to be analyzed). The freshly mixed plaster/water mass should be poured inside the channel, so that the surface is leveled, which must be then covered by the PTFE sheet, basically keeping the aforementioned length. Immediately, the micrometer should have its tip touching the mobile block, moment in which the ring should be turned until the pointer is adjusted on zero; this will be considered as the initial reading and should always be taken at 60 s after the plaster insertion in the channel; the final measurement should be taken at 120±1 min, counting from the beginning of the mixture of the original components. The setting expansion should be calculated as the percentage of the original length, by about the second decimal point, for a minimum of two valid tests.

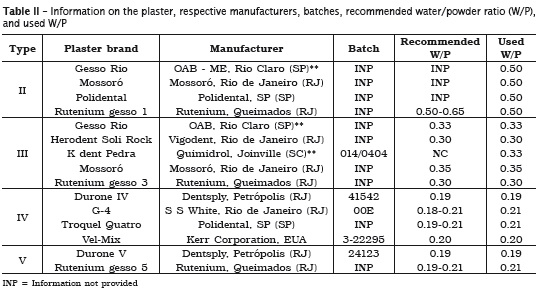

Five tests were performed for each one of the plasters of table II, which displays the manufacturers, batches, water/powder ratio indicated by the manufacturer and the water/powder ratio used.

To make each specimen, 100±1 g of gypsum, weighed in an electronic scale Sauter K 1200, (August Sauter GmbH., Balingen, Germany), with accuracy of 0.01 g and capacity of 120 g, were mixed with the amount of deionized water corresponding to W/P recommended by the manufacturer; if the manufacturer did not provide this information, the general guideline for each plaster type was followed.

Firstly, the components were mixed with the aid of a metallic spatula, for 10 seconds and, then, with the aid of vacuum mixer VAC-U-VETOR, model B (WHIP-MIX, Louisville, KY, EUA), set at 22 mmHg of pressure, for 15 seconds. After that, the material was poured under vibration into the channel of the device coupled to the extensometer, up to the guide mark established by ADA1 and ISO5 Specifications and at a length of 10 cm. The guide piece (mobile block) was fixed to the upper wing of the auxiliary rod, though a screw until the moment of the final vibration. The channel was covered by PTFE sheet of 0.1 mm of thickness (3M, Sumaré, SP, Brazil); the channel areas in touch with plaster were covered by solid Vaseline.

After the channel filling, other PTFE sheet was placed onto the surface of the fluid material to avoid water evaporation from the fluid mixture. In order that the material length was 10 cm (100.000 μm) horizontally inside the channel, a 10-cm metallic guide cylinder was previously inserted inside it, after the locking of the guide piece through the screw on the rod above it.

The aforementioned expansion device together with the guide cylinder and the micrometric clock is shown in figure I.

The screw was released after 5 minutes (counting from the beginning of the mixture), for all specimens. Thus, to establish the initial length, the micrometric clock pointer was adjusted to zero. The expansion values were recorded after more 120 minutes. The obtained data were converted in expansion percentage of the initial plaster length (10 cm), which is the length of the guide cylinder.

Results

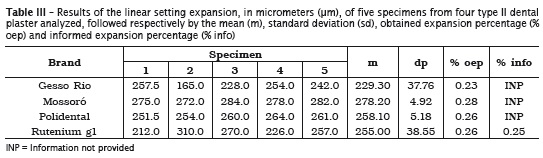

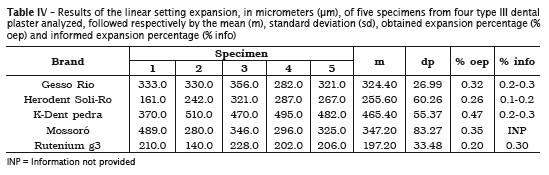

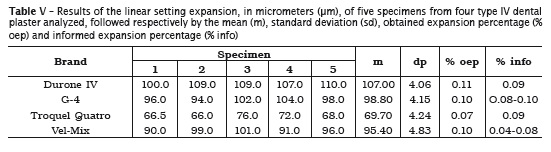

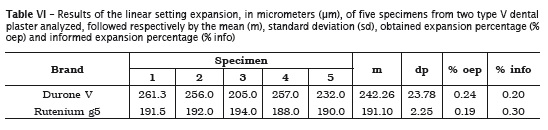

The observed values of the linear setting expansion of each specimen, followed by the mean and standard deviation values, for each plaster type, are seen in tables III, IV, V and VI, respectively for types II, III, IV, and V. The last two columns of each table displays, respectively the percentage value of the expansion detected in this study, followed by that informed by the manufacturer.

All analyzed type II dental stones met ISO5 and ADA1 Specifications. Concerning to types III, only "Rutenium gesso 3" met the limits. All type IV dental stones showed setting expansion lower than that required by the aforementioned associations, except for Durone IV, presenting a mean value 0.01% above ADA specification values, but within ISO specification values. The type V dental stones were within the required limits.

Discussion

To evaluate the linear setting expansion of dental stone ADA1 demands a series of specifications: the extensometer cited above must be used, the channel must be lined with a PTFE sheet, the fluid water/stone mass poured into the channel does not exceed the length of 36 cm, two markers (far between 30 cm) should be placed on the surface of the plaster and this exact distance must be assessed "1 minute before the setting time"; the distance ending must be checked 2 hours after dental stone manipulation. For the same purpose, ISO5 demands the use of a extensometer, also comprising a similar channel whose material is not informed, with the aforementioned shapes and sizes, also covered by PTFE sheet; the channel must be closed by one of the endings by a fixed piece existing in the free ending of the mobile block. Immediately after the fluid mixture is poured into the channel, a micrometer should have the pointer touching the mobile block, moment when the ring should be rotated until its pointer is adjusted in the zero mark; reading which will be considered the initial and should be taken at 60±1 seconds before the final setting occurs, understood by another item explained in the Specification. The final measurement should be taken at 120±1 minutes, counting since the beginning of the mixture of the original components; the setting expansion should be calculated as the percentage of the original length, of about the second decimal, for at least two valid tests.

A careful reading of the standards referred herein supports the conclusion that they have essentially the same effect independent of the measuring device. The small differences between them are found, for example in expansion rates required for the different types of plasters.

In this study, we basically followed all of those requirements. The modification made to fix the movable part now allows the efficient vibration of the mixture (prior to leak in the channel) while maintaining the distance provided by the guide device.

Some companies provide confusing information, both on the labels of their products and in the respective package inserts and even in advertising materials. Often there is no indication of W/P ratio, manufacture date, batch number, and expiry date. The names given to plaster by manufacturers often cause confusion. So that now difficulties were also detected in identifying the type of some products, according to the ADA specifications1, as some manufacturers have created confusion, for example, placing the name of your product (trade name) as a type 1 plaster (in Arabic numerals), when such material is actually the type II (in Roman numerals, as shown in ADA specifications1).

Another serious problem is that related to the water/powder (W/P). Often this information is not included with the product, as already mentioned. In many cases, when it exists and is followed, the minimum flow required by ADA is not achieved1.

Then, the directions of the manufacturers were always followed regarding to the W/P ration. In the absence of this information, it was decided to use the mean value reported by other products of the same type, as long as the flowing appeared to be appropriate, during the act of pouring the material into the channel. By considering the results obtained and the percentage rates of the expansion allowed by ADA1 and ISO5, the following conclusions can be made.

Remembering that for dental stone called common (type II), for both cited specifications, a maximum of 0.30% is required. It was observed that only one of the analyzed stones (Ultra Herodent Cal) exceeded the limit.

For dental stone (type III), with both specifications mentioned requiring a maximum of 0.20%, it was observed that only one of the analyzed stone (Rutenium 3) met the requirements, having a lower expansion ratio than said in its packaging. All other stones of this type, in addition to having higher rates than required, had higher expansion rates than those contained in their packaging.

For high-strength stone (type IV), the first of the mentioned specifications is allowed a maximum of 0.10% and in the second, a maximum of 0.15%. It was observed that almost all stones met the requirements, because Durone IV showed slightly more expansion than that required by ADA, but less than that required by ISO.

For dental stone high strength and expansion (type V), the first specification required a maximum of 0.10%, while the second specification requires 0.15%. It was observed that both plasters exceed these limits and that the rate observed for Durone V was lower than that reported by the manufacturer, the opposite occurring for Rutenium gesso 5.

It is common knowledge that the stone types II and III are commonly used to obtain diagnostic models and working models, and this it is important containing minor dimensional changes9.

By the same method used in this study, using the channel, Michalakis et al.9 observed an expansion mean, considering type II dental stone after 2 hours, of 0.3 and 0.47% for Model Plaster (Heraeus Kulzer GmbH, Hanau, Germany) and Lab Plaster (Dentsply, Tulsa, OK, USA), respectively. In this present study, a mean of 0.23-0.28% was observed, compatible with the values of the aforementioned study. By considering the dental stone (type III), Michalakis et al. 9 obtained 0.15% as the result for linear expansion (Mounting Stone – Whip Mix). In this present study, we evaluated more products; however, they are different from those used in the study cited above; anyway, a mean between 0.2 and 0.47% of expansion.

At the beginning of mixing of the gypsum powder with water, there is a volumetric shrinkage7; over time, gypsite crystals are formed and an isotropic expansion can be observed3,12, which continues up to 120 hours4, although the Specification n. 25 of ANSI/ADA1 recommends the reading of the expansion for until 2 hours, the amount of time used in this study.

Type IV and V dental stones have been used in the process of construction of definitive restorations. Thus, their dimensional stability is of fundamental importance for the final restoration outcome.

The results obtained by this present study agree with those of the study of Michalakis et al. 8, who evaluated the setting expansion of type IV and V dental stones, basically obtained the same results verified in this present study. Exemplifying, for Vel- Mix, after 2 hours, a mean expansion of 0.09% was found in the study cited above, while this present study found 0.1%. In the assessment evaluated at 96 hours (by Michalakis et al.), Vel-Mix presented an expansion of 0. 15%, mostly occurring at the first 2 hours, but with a new expansion spurt after 24 hours; then a stability of about 3 weeks was seen, occasion in which the aforementioned authors detected the regress for the same expansion values observed after 2 hours (0.09%).

In type IV dental stones studied by Michalakis et al.8, in 2012, the dimensional alteration varied from 0.07 to 0.09%, while in this present study the dimensional alteration was of 0.07 to 0.11%. For the two type V dental stones, they observed a dimension alteration of 0.29 and 0.16%, respectively for Hard Rock and Jade Stone, both manufactured by Whip Mix Corporation.

In this present study, it was observed an alteration of 0.24 and 0.19% for Durone V and Rutenium gesso 5, respectively. The similar results validate the different methods used in this present study and in the study of Michalakis et al. These authors used a metallic taper device with horizontal and vertical slots by using the optical microscope to evaluate the dimensional alterations.

It is vital to emphasize that this study closely followed the recommendations of the respective manufacturers, both regarding the dosage of the products and the handling process. As claimed by Michalakis et al.9, failure to follow these precautions changes the properties of the final product, especially as regards to the water: powder proportion; the water excess increases the hygroscopic expansion, since it causes greater growth of gypsite crystals. The different expansion rates for different products reflect different qualities.

Conclusion

Considering the limitations of this present study, and the limits established by ADA and ISO specifications, types II, IV, and V dental stones met the specifications, except for Durone IV. Considering type III dental stones, only Rutenium gesso 3 met the specifications.

It is need to constantly keep an assessment of the linear setting expansion of gypsum used in dentistry.

Acknowledgements

The authors thank Fapesp by the financial support (Process n. 03/02759-2).

References

1. American Dental Association. New American Dental Association specification n. 25 for dental gypsum products. J Am Dent Assoc. 1972 Mar;84(3):640-4. [ Links ]

2. Chang WG, Vahidi F, Bae KH, Lim BS. Accuracy of three implant impression techniques with different impression materials and stones. Int J Prosthodont. 2012 Jan-Feb;25(1):44-7.

3. Duke P, Moore BK, Haug SP, Andres CJ. Study of the physical properties of type IV gypsum, resincontaining, and epoxy die materials. J Prosthet Dent. 2000 Apr;83(4):466-73.

4. Heshmati RH, Nagy WW, Wirth CG, Dhuru VB. Delayed linear expansion of improved dental stone. J Prosthet Dent. 2002 Jul;88(1):26-31.

5. International Organization for Standardization. International standard ISO 6873 / Dental gypsum products. 2. ed. 1998.

6. Lautenschlager EP, Corbin F. Investigation on the expansion of dental stone. J Dent Res. 1969 Mar-Apr;48(2):206-10.

7. Mahler DB, Ady AB. An explanation for the hygroscopic setting expansion of dental gypsum products. J Dent Res. 1960 May-Jun;39:578-89.

8. Michalakis KX, Asar NV, Kapsampeli V, Magkavali-Trikka P, Pissiotis AL, Hirayama H. Delayed linear dimensional changes of five high strength gypsum products used for the fabrication of definitive casts. J Prosthet Dent. 2012 Sep;108(3):189-95.

9. Michalakis KX, Stratos A, Hirayama H, Pissiotis AL, Touloumi F. Delayed setting and hygroscopic linear expansion of three gypsum products used for cast articulation. J Prosthet Dent. 2009 Nov;102(5):313-8.

10. Pal PK, Kamble SS, Chaurasia RR, Chaurasia VR, Tiwari S, Bansal D. Evaluation of different disinfactants on dimensional accuracy and surface quality of type IV gypsum casts retrieved from elastomeric impression materials. J Int Oral Health. 2014 Jun;6(3):77-81.

11. Vigolo P, Fonzi F, Majzoub Z, Cordioli G. An evaluation of impression techniques for multiple internal connection implant prostheses. J Prosthet Dent. 2004 Nov;92(5):470-6.

12. Winkler MM, Monaghan P, Gilbert JL, Lautenschlager EP. Comparison of four techniques for monitoring the setting kinetics of gypsum. J Prosthet Dent. 1998 May;79(5):532-6.

Corresponding author:

Corresponding author:

Adilson Yoshio Furuse

Al. Dr. Octávio Pinheiro Brisolla, 9-75 – Bauru

CEP 17012-901 – Bauru – SP – Brasil

E-mail: furuse@usp.br

Received for publication: December 1, 2014

Accepted for publication: December 22, 2014