Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RSBO (Online)

versão On-line ISSN 1984-5685

RSBO (Online) vol.12 no.2 Joinville Abr./Jun. 2015

Original Research Article

Silanization effect on microtensile bond strength of a self-adhesive luting material to a disilicate-based glass ceramic

Cristina Parise GréI; Guilherme Carpena LopesI; Sylvio Monteiro JúniorI; Élito AraújoI

I Department of Dentistry, Federal University of Santa Catarina – Florianópolis – Santa Catarina – Brazil

ABSTRACT

Introduction: The rehabilitation of teeth by means of ceramic indirect restorations has been widely performed. Previous studies has shown the effectiveness of silane coupling agents on improving the bond strength of the adhesion of resin cements to ceramics; however, some studies question the use of silane. Objective: To evaluate the effect of silane application on the microtensile bond strength of an auto-adhesive luting material to a lithium disilicate glass-ceramic. Material and methods: Two blocks (9x11x4mm) of lithium disilicate glass-ceramic had one of their surfaces polished (# 220, 360, 600 grit silicon-carbide abrasive papers) and cleaned ultrasonically. The ceramic blocks were then divided into two groups according to the surface treatment: G1 (control group): etched with 10% hydrofluoric acid for 20s and silane coated; G2: etched with 10% hydrofluoric acid for 20s. After building two blocks of composite resin (Filtek Z350) with the same dimensions of the ceramic blocks, the self-adhesive resin cement (SpeedCEM) was applied directly to the ceramic surface and the resin block was seated on the cement. After storage (24h, 37°C), the ceramic-cement-composite blocks were cut with an Isomet low-speed diamond saw machine producing sticks, which were loaded to failure at a crosshead speed of 0.5 mm/min. The type of fracture was analyzed under an optical microscope. The results were statistically analyzed using the Student t test. Results: The mean microtensile and standard deviations in megaPascals were: G1 = 21.32 (± 4.36) and G2 = 16.55 (± 4.92). Statistical analysis showed that the bond strength was not significantly affected by the surface treatment with silane. Most of the fractures occurred within the adhesion zone. Conclusion: The application of silane had no significant effect on the bond strength between lithium disilicate glass-ceramic and self-adhesive resin cement.

Keywords: silane; microtensile; lithium disilicate; ceramic.

Introduction

The rehabilitation of teeth by means of indirect restorations in ceramic has been increasingly performed 1, 18. A growing number of ceramic systems cemented by adhesive technique are available for clinical use and many studies have reported clinical long-term success of this restoration type 4.

The clinical success of ceramic restorations cemented by the adhesive technique is highly dependent on a stable and durable adhesive bond 23. Such union is dependent on the surface energy and the degree of wett ing of the adhesive by the adhesive 9. The adhesion between dental ceramics and composite resins is the result of physical-chemical interaction through the interface between the adhesive and the substrate 9, which can be achieved by two mechanisms: 1) micromechanical adhesion by use of hydrofluoric acid and/or sandblasting; and 2) chemical adhesion through a silane coupling agent 13. The hydrofluoric acid removes the glass matrix and the second crystalline phase, creating irregularities on IPS e.max lithium disilicate crystals, allowing mechanics adhesion to resin composites 5. The silane coupling agent has bifunctional characteristics promoting chemical interaction between the silica layer of the vitreous phase of ceramics and the methacrylate groups of resins through siloxane bonds 19.

The etching of the sur face and si lane application increases the surface energy and the degree of wetting of the ceramic surface 2, 6.

Silane coupling agents are used since 1949 to improve the union of adhesives (of organic nature), ceramics and metals, but only in 1977 Eames and colleagues suggested the use of silanes in dentistry 12.

Previous studies have reported the effectiveness of the silane coupling agent to increase the bond strength between composite resins and ceramics 10, 17 and between resin cements and ceramics 6, 16, 25; however, some studies 9, 11, 20, 27 doubt on the use of silane. Authors state that the application of silane had no significant effect on the bond strength between ceramics and resin cements 9, 11, 27.

Such materials using adhesive system through total etching or self-etching agents, followed by applying a composite resin of low viscosity 7, which makes their use complicated and may interfere with adhesion. Adhesive systems that combine adhesive and cement in a single application have been introduced to the market 11. The self-adhesive resin cement tested in this study contains, according to the manufacturer, adhesive monomers formed by a long methacrylate chain with a phosphoric acid group able to establish chemical bonds to the tooth structure and to ceramic surfaces. Thus, additional bonding agents are not required 14.

Recently introduced in the market, the glassceramic- based lithium disilicate IPS e.max Press (Ivoclar Vivadent, Schaan, Liechtenstein) offers excellent esthetics and features, according to the manufacturer, high flexural strength values (± 400 MPa). The manufacturer recommends the use of hydrofluoric acid associated with a conventional silane agent for bonding procedures due to the glass phase present in these ceramics 15.

This study evaluated the influence of silane coupl ing agent appl icat ion on microtensi le bond strength of self-adhesive resin cement to lithium disilicate reinforced glass ceramic, the IPS e.max system. The tested null hypothesis is that there was no inf luence of silane coupling agent application on the bond strength of selfadhesive resin cement to lithium disilicate-based ceramics.

Material and methods

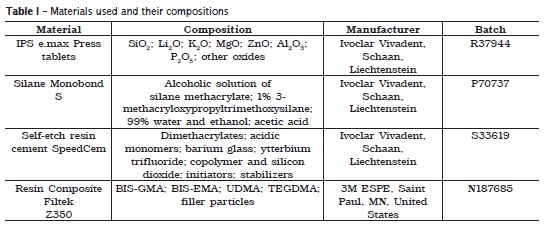

Two blocks, each measuring 11 mm long x 9 mm in width x 4 mm in height, were made of wax casting, included in coating (IPS e.max Press), and the ceramic was infiltrated under pressure in EP 500 special oven. The obtained ceramic blocks were sandblasted with aluminum oxide to remove the coating.

For standardization, a surface of each ceramic block was polished, refrigerated, in a polishing machine (Panambra, SP, Brasil), with sandpaper (Acqua Flex-Norton, SP, Brasil) e in descending order of granulation - 220, 360 600 - cleaned in ultrasonic bath with distilled water for 5 min and dried with compressed air. The blocks were then divided into two groups according to the surface treatment they were submitted to:

• Group 1 (control): etching with 10% hydrofluoric acid (Condac porcelana, FGM, Joinville, SC, Brazil) for 20 s, rinsing with compressed air / water jet for 30 s, air drying for 30 s, followed by silane application (Monobond S-Ivoclar Vivadent, Schaan, Liechtenstein). After 60 s, silane reaction time, the surfaces were dried with compressed air jet for 30 s;

• Group 2: etching with 10% hydrofluoric acid for 20 sec, rinsing with compressed air/water for 30 s, air drying for 30 s without the subsequent application of silane.

Following, two composite resin blocks (Filtek Z350, shade A2, 3M ESPE, St. Paul, MN, USA) with the same dimensions of the ceramic blocks were made. Therefore, each ceramic block was submitted to impression with polymerized addition silicon (Virtual, Ivoclar Vivadent; Schaan, Liechtenstein) to obtain a matrix. The composite resin was inserted in the array at 2 mm increments, and each increment was light-cured for 20 s by a light-curing unit (Translux Power Blue-Hareaus Kulzer GmbH-Hanau, Germany) with light intensity (750mW/cm2) measured prior to its use by a radiometer.

After the surface treatment of ceramic and the resin blocks already ready, the self-adhesive resin cement SpeedCem (Ivoclar Vivadent; Schaan, Liechtenstein) was applied directly on the ceramic surface. The resin block was sitting onto the cement and, to standardize the load cementing of the ceramic-polymer-cement assembly, at the moment of the resin block sitting, a cementing device with a load of 1 kg was used.

After 24h in distilled water at 37oC, the specimens were placed in the cutting machine (ISOMET 1000, Buehler, Lake Bluff, IL, USA) for manufacturing the sticks for the microtensile test. The blocks were sectioned at ceramic-resin direction, resulting in sticks with cross-sectional area of approximately 0.8 mm2. The width and thickness of the sticks were measured with a digital caliper (KingTools, São Paulo, SP, Brazil) with a precision of 0.01 mm, and 25 specimens of each group were randomized to be submitted to microtensile test.

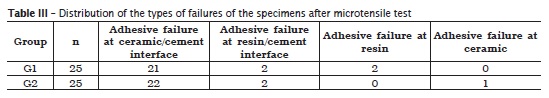

The sticks were individually glued at their ends to a special microtensile device (Geraldeli device for microtensile) adapted to a universal testing machine (Instron, model 4444, Instron Corp. Canton, MA, USA), and microtensile test was performed at a crosshead speed of 0.5 mm/min until the fracture. The type of fracture was assessed by optical microscope (Olympus BX 60, Olympus Optical do Brasil Ltd., São Paulo, SP, Brazil) at x20 magnification. The fractures were classified as adhesive (as occurred in the adhesive interface), cohesive in ceramic (when occurring in the ceramic substrate), cohesive in resin (when occurring in composite resin) and mixed (when involved more than one substrate). The microtensile bond strength was calculated and the values were expressed in MPa. The results were evaluated through Student's t-test with 0.05 significance level.

Results

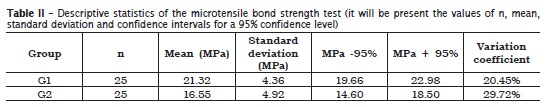

The Student t test showed no significant difference between the groups tested (p > 0.05). The microtensile bond strength was not significantly affected by silane application to the ceramic surface.

The mean bond strength (MPa) and the standard deviation found in G1 and G2 were: G1 = 21.32 (± 4.36) and G2 = 16.55 (± 4.92) (table II). It was found a value of p = 0.787 and, and therefore the null hypothesis was accepted. The pre-test failures were 8.33% for G1 and 6.89% for G2; however these failures were not considered for determining the mean and statistical analysis.

Most fractures occurred in the adhesive interface between the ceramic and resin cement, in both groups (table III).

Discussion

Several factors are relevant to the success of ceramic restorations cemented adhesively, because it is essential to create a stable and lasting adhesion. Several methods are available to evaluate the bond strength. One of the tests more used is the shear bond strength test, which often produces cohesive fractures in substrate, far from the adhesive area due to poor stress distribution at the testing time, generating erroneous results 8, 23.

In this study we used the microtensile test, recommended by Sano and colleagues 24, but without additional wear for preparing the hourglass shape specimens 26, seeking a better stress distribution at the adhesive interface. The adhesive area of the specimens prepared in this study was approximately 0.8 mm2, allowing a more uniform stress distribution at the moment of load application, and prevailing failures in the adhesive interface.

The results of this study showed that the application of silane coupling agent on the ceramic surface did not influence the microtensile bond strength values of the self-adhesive resin cement to glass ceramic.

The silane application on the surface of glass ceramics after etching with hydrofluoric acid is an established surface treatment in the literature, for generating good bond strength values 3, 10. Due to its bifunctional characteristics, the silane application to the etched ceramic surface improves the bond of ceramics to resin materials since the silane coupling agent is able to bond, through siloxane bonds, the silica present in ceramic surface to the resin organic matrix 19.

Differently from studies that prove the effectiveness of silane coupling agent in improving the bond strength of resin cements to ceramics 6, 21, 25, in this study, the application of silane after the ceramic acid etching did not influence on the bond strength of the self-adhesive resin cement to lithium disilicate based ceramics. This result suggests that a chemical reaction between the selfadhesive resin cement and glass ceramic occurred, probably based on an interaction between the phosphoric acid group present in the resin cement and ceramic surface oxides, making unnecessary the silane application in cases which this chemical bond is effective 20.

This study agrees with previous and studies quest ioning the use of si lane in previously condit ioned ceramic surface. Sorensen and colleagues 27 reported no difference in the amounts of shear bond strength of ceramic to resin cements between silanized and non-silanized groups. For Della Bona et al. 9, surface treatment with silane coupling agent decreased the energy surface of the ceramic, which reduced the degree of wetting of the surface by the resin cement. According to Oliveira and colleagues 20, silanization did not improved shear bond strength values of self-adhesive resin cements to glass fiber posts because the post's surface became non-polar, which would impair the wetting of the post surface by the cement. Dos Santos et al. 11 also reported no difference in bond strength values of composite resin to resin self-adhesive cement between silanized and nonsilanized groups.

As mentioned above, the silanization may be unnecessary when effective chemical bond of the self-adhesive resin cement to the glass phase of the ceramic occurs. A possible explanation for these results is that the silane layer may restrict the interaction between the acid groups present in phosphoric acid groups from the self-adhesive cement and the glass ceramic layer 20.

Studies show that the conditioning of the ceramic by hydrofluoric acid creates micro retentions that cause satisfactory adhesion results of resin cement to ceramics conditioned by acid 6, 28. Therefore, both groups herein tested underwent etching by hydrofluoric acid.

Conclusion

The application of silane coupling agent on a ceramic surface previously conditioned by hydrofluoric acid did not increase the microtensile bond strength of self-adhesive resin cement to a lithium disilicate-based glass ceramic.

References

1. Abou Tara M, Eschbach S, Wolfart S, Kern M. Zirconia ceramic inlay-retained fixed dental prostheses – first clinical results with a new design. J Dent. 2011 Mar;39(3):208-11.

2. Addison O, Marquis PM, Fleming GJ. The impact of hydrofluoric acid surface treatments on the performance of a porcelain laminate restorative material. Dent Mater. 2007 Apr;23(4):461-8.

3. Anagnostopoulos T, Eliades G, Palaghias G. Composition, reactivity and surface interactions of three dental silane primers. Dent Mater. 1993 May;9(3):182-90.

4. Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003 Mar;89(3):268-74.

5. Borges GA, Sophr AM, Goes MF, Sobrinho LC, Chan CN. Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J Prosthet Dent. 2003 May;89:479-88.

6. Brentel AS, Ozcan M, Valandro LF, Alarca LG, Amaral R, Bottino MA. Microtensile bond strength of a resin cement to feldspathic ceramic after different etching and silanization regimens in dry and aged conditions. Dent Mater. 2007 Nov;23(11):1323-31.

7. Broyles AC, Pavan S, Bedran-Russo AK. Effect of dentin surface modification on the microtensile bond strength of self-adhesive resin cements. J Prosthodont. 2013 Jan;22(1):59-62.

8. Chadwick RG, Mason AG, Sharp W. Attempted evaluation of three porcelain repair systems – what are we really testing? J Oral Rehabil. 1998 Aug;25(8):610-5.

9. Della Bonna A, Shen C, Anusavice KJ. Work of adhesion of resin on treated lithia disilicate-based ceramic. Dent Mater. 2004 May;20:338-44.

10. Della Bonna A, Anusavice KJ, Shen C. Microtensile strength of composite bonded to hot-pressed ceramic. J Adhes Dent. 2000 Winter;2(4):305-13.

11. Dos Santos VH, Griza S, de Moraes RR, Faria-E-Silva AL. Bond strength of self-adhesive resin cements to composite submitted to different surface pretreatments. Restor Dent Endod. 2014 Feb;39(1):12-6.

12. Eames WB, Rogers LB, Feller PR, Price WR. Bonding agents for repairing porcelain and gold: an evaluation. Oper Dent. 1977;2(3):118-24.

13. Hoosmand T, Van Noot R, Keshvad A. Bond durability of the resin-bonded and silane treated ceramic surface. Dent Mater. 2002 Mar;18: 179-88.

14. Ivoclar Vivadent [access in 2014 Oct 28]. Available at: http://www.ivoclarvivadent.com/en/ products/luting-material/self-adhesive-resin-cement/ speedcem.

15. Ivoclar Vivadent [access in 2014 Oct 28]. Available at: http://www.ivoclarvivadent.com/en/products/.

16. Kamada K, Yoshida K, Atsuta M. Effect of ceramic surface treatments on the bond of four resin luting agents to a ceramic material. J Prosthet Dent. 1998 May;79(5):508-13.

17. Kupiec KA, Wuertz KM. Evaluation of porcelain surface treatments and agents for compositeto- porcelain repai r. J Prosthet Dent. 1996 Aug;76(2):119-24.

18. Maeda FA, Bello-Silva MS, de Paula Eduardo C, Miranda Junior WG, Cesar PF. Association of different primers and resin cements for adhesive bonding to zirconia ceramics. J Adhes Dent. 2014 Jun;16(3):261-5.

19. Matinlinna JP, Lassila LV, Ozcan M, Yli-Urpo A, Vallittu PK. An introduction to silanes and their clinical applications in dentistry. Int J Prosthodont. 2004 Mar-Apr;17(2):155-64.

20. Oliveira AS, Ramalho ES, Ogliari FA, Moraes RR. Bonding self-adhesive resin cements to glass fibre posts: to silanate or not silanate? Int Endod J. 2011 Aug;44(8):759-63.

21. Ozcan M. Evaluation of alternative intraoral repair techniques for fractured ceramic-fusedto- metal restorat ions. J Oral Rehabil. 2003 Feb;30(2):194-203.

22. Pashley DH. Regional measurement of resindentin bonding as an array. J Dent Res. 1999 Feb;78(2):699-705.

23. Pollington S, Fabianelli A, Van Noort R. Microtensile bond strength of a resin cement to a novel fluorcanasite glass-ceramic following different surface treatments. Dent Mater. 2010 Apr;26: 864-72.

24. Sano H, Shono T, Sonoda H, Takatsu T, Ciucchi B, Carvalho R et al. Relationship between surface area for adhesion and tensile bond strength: evaluation of a micro-tensile bond test. Dent Mater. 1994 Jul;10(4):236-40.

25. Sato K, Matsumara H, Atsuta M. Effect of three-liquid bonding agents on bond strength to a machine-milled ceramic material. J Oral Rehabil. 1999 Jul;26(7):570-4.

26. Shono Y, Ogawa T, Terashita M, Carvalho RM, Pashley EL, Pashley DH. Regional measurement of resin-dentin bonding as an array. J Dent Res. 1999 Feb;78(2):699-705.

27. Sorensen A, Engelman J, Torres J, Avera P. Shear bond strength of composite resin to porcelain. Int J Prosthodont. 1991 Jan-Feb;4(1):17-23.

28. Wolf DM, Powers JM, O'Keefe KL. Bond strength of composite to etched and sandblasted porcelain. Am J Dent. 1993 Jun;6(3):155-8.

Correspondence:

Correspondence:

Cristina Parise Gré

Disciplina de Dentística – Sala 138

Universidade Federal de Santa Catarina

Campus Universitário – Trindade

CEP 88040-970 – Florianópolis – SC – Brasil

E-mail: c_sufi@hotmail.com

Received for publication: July 14, 2014

Accepted: February 19, 2015