Serviços Personalizados

Artigo

Links relacionados

Compartilhar

RSBO (Online)

versão On-line ISSN 1984-5685

RSBO (Online) vol.12 no.3 Joinville Jul./Set. 2015

ORIGINAL RESEARCH ARTICLE

Effect of contact time between alginate impression and type III dental stone on cast model properties

Amna Adam IbrahimI,II; Mohammed Nasser AlhajjI,III; Magdi Wadie GiladaI

I Department of Oral Rehabilitation, Faculty of Dentistry, Khartoum University – Khartoum – Sudan

II Department of Prosthodontics, Faculty of Dentistry, Al-Gazira University – Wad Medani – Sudan

III Department of Prosthodontics, Faculty of Dentistry, Thamar University – Thamar – Yemen

ABSTRACT

Objective: To measure the effect of different contact time between the alginate impression and type III dental stone on cast model properties in the terms of dimension stability, hardness and surface details reproduction. Material and methods: Sixty-seven cast models were obtained from stainless steel cylinder using alginate impression material and type III dental stone. Thirty-seven cast models were separated after one hour (control group) and 30 cast models were separated from impressions after 9 hours. The samples were evaluated under light microscope for surface details, measured by digital caliper for dimension stability and hardness was tested by making indentation on the cast then measuring the depth using digital caliper. Results: The dimension stability of cast models was not affected by increasing contact time between type III dental stone and alginate impression while surface details decreased. In the meanwhile, hardness was improved with increasing contact time. Conclusion: According to the results of this study, pouring of impression up to 9 hours can negatively affect the cast model properties in the term of details richness.

Keywords: alginate impression; dental stone; contact time; cast model properties.

Introduction

In dentistry, there is a need for a replica of oral-dental tissues for diagnosis and treatment of oral diseases 11,19. These replicas are made from impressions that poured to make what called cast model or die 14,19,21. The most extensively used materials for this purpose are alginate and gypsum products 8. The alginate is a hydrocolloid material used in dentistry since 1940 because of its easy mixing, low cost and well accepted by patient 8,15,17. It consists of a powder containing calcium or potassium sulfate and fillers as primary components. Commercial alginate has some additives to calcium salt which improves its properties such as diatomaceous earthfiller to increase rigidity and facilitate mixing, tetra sodium pyrophosphate (retarder), magnesium oxide (pH modifier) and setting aids such as sodium fluorosilicate 2,14. This product is regulated by ISO 1563:1990 and its properties are described in ANSI/ADA specification no. 18-1992 for alginate impression materials 2.

Unfortunately, alginate is not dimensionally stable thus it is necessary to pour the impression immediately after molding has been accomplished 12,15 or within up to 60 minutes if the impression is kept in 100% humidity 23. These changes in dimension can be explained by two main phenomenons; syneresis which results in impression contraction and imbibition that makes the impression expands 12,14. The ADA specification no 18 accept an error of 75 μm in the alginate impression as a maximum dimension change2.

It is of a good practice to separate the impression from the cast before the hydrocolloid dehydrates because that the dried alginate can cause abrasion on the cast during its removal 7. Working cast model and die of gypsum used in fabrication of dental restoration must provide dimensional stability, strength, and resistance to abrasion as well as they must reproduce surface details 5. Specification no. 25 of ADA revealed that details reproduction is satisfactory when a copy line of 50μm in diameter reproduced continuously across the stone cast. These details can be affected by the type of impression material used and disinfection method 1,3,4,10.

Hardeners are added to stone to improve the hardness of the cast. Cyanoacrylate increases the surface hardness 150% and abrasion resistance 48% 6,9. Although some studies showed that the surface hardness was not affected by impression disinfection 22, others disagree with these results13. The dimension stability of the cast model is not only affected by alginate syneresis and imbibition but also depends on the clinician handling of alginate impression and prolongs contact time between alginate impression with gypsum product 14,20. The hypothesis that was tested in this study was that the effect of contact time between alginate impression and type III dental stone on model properties after different interval periods.

Material and methods

For conduction of this study a stainless cylindrical model was constructed according to ADA specification no. 18 for alginate impression material 2. The dimensions of the cylindrical model were 25 mm in width and 15 mm in length with reference lines in surface 75 μm, 50 μm and 25 μm in width and 2.5 mm apart from each other. These lines were used to measure surface details reproduction. Two bisecting lines (x and x') were marked to test the dimension stability by measuring the distance in between. The hardness was assessed by making indentation along the 50μm longitudinal line and measuring the micro scratches 2,10,23. Ten special trays were made from chemical cure acrylic resin (Superacryl Plus, SpofaDental, Markova, Czech). Two wax sheets (2.8 mm in width) evenly lied around the cylinder then acrylic dough was applied to grantee an equal width of alginate impression material around the cylinder. After material setting, the special trays were finished and perforated. All impressions of the cylinder were made using high precision, chromatic alginate (Alginmax, Major, Moncalieri, Italy) and the instructions of the manufacturer were followed. The impressions were poured with type III dental stone (Gyproc, Prevest Denpro, Jammu, India) to produce the cast models. Sixty-seven cast models were obtained from impressions after different interval times, they were randomly divided into two groups; Group A (no=37): is the control group where the casts were removed after one hour, and Group B (no=30): is the study group where the casts were removed after 9 hours. All casts were preserved for 48 hours in well-sealed plastic bag until testing. All properties were carried out by one examiner.

The properties of the resultant casts were tested as follows:

Survey groups and sample size

The dimension stability measured indirectly from the cast between x and x' along the 50μm line by using digital caliper (Digital Caliper, Hornady, New York, USA).

Surface details examination

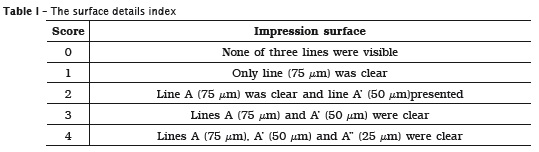

The surface details were evaluated by reproduction of A, A', A'' according to the scores index (table I). Evaluation was performed under x4 magnification and 100 watt artificial light (VanGuard, VEE GEE Scientific, Kirkland, USA).

Hardness examination

Hardness was measured by depth of indentation made by 997 Newton in 15 seconds. The casts were mounted on the machine (W&T, Avery, Birmingham, England) to accommodate the ball along the 50μm line. The cast was released and measuring of the indentation was performed using digital caliper.

Results

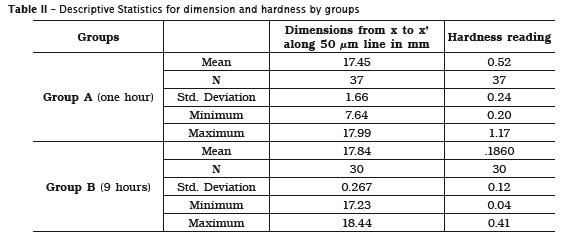

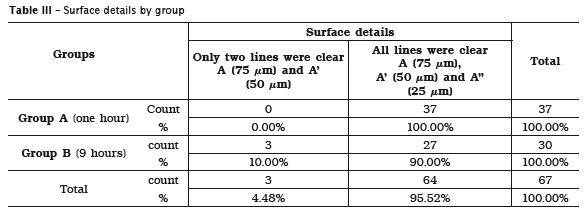

Stat ist ical Package for Social Sciences Software (SPSS V20, IBM, Chicago, USA) was used to perform the statistical analysis. Table II shows the descriptive statistics of dimension stability in mm and hardness measured along the 50μm line. Student's t-test was utilized to measure the significance of differences between the groups. There was no significant difference (P-Value = 0.120) in the term of dimension stability between the two groups while high significant difference (P-Value=0.0001) in hardness readings existed. Regarding surface details the results of the study shows that the two groups could duplicate two lines clearly 50 μm and 75 μm (table III). For analyzing the comparison in surface details between the two groups Mann- Whitney non-parametric test was applied because the data is not quantitative (ordinal scale). No significant difference between group A and group B was observed (P-Value=.051).

Discussion

In daily dental practice immediate pouring of the alginate impressions may not be always accessible. Thus, the impressions are wrapped in a paper towel or saved in a well-sealed bag with appropriate humidity. Failure to achieve these requirements will affect the properties of these materials 18. Nevertheless, taking a long time to separate the cast from the impression will result in deterioration on some properties of the model cast. This study was set out to investigate the possible changes of the properties on the cast model after different time contact between the gypsum type III dental stone and alginate impression material. The results showed that there were no significant changes in the dimension stability of the stone cast models in different periods. Surface details and hardness evaluation showed differences among the two tested groups. The hardness significantly increased with increase contact time while the surface details richness decreased with increase contact time. Despite this, very few studies have investigated the impact of the prolonged contact time between alginate impression and dental stone.

Marquezan et al. 15 found that the contact time between alginate impression material and type III dental stone did not affect the dimension of cast models. Although their study was conducted to test the properties between one hour and 12 hours of contact time the results regarding the dimension stability was also as that obtained from this study which compared the results between one hour and 9 hours of contact time. The surface details were not destroyed in this study, the two groups duplicate lines 75 μm and 50 μm clearly which are satisfied according to ADA specification no 18 for alginate impression material, and no. 25 for gypsum product respectively 1,2.

All model casts of Group A (one hour contact time) could reproduce the line 25 μm whereas about 10% of Group B samples (nine hours contact time) failed to reproduce that line. This might indicate that increased contact time between alginate impression material and stone can affect the richness of details. On the other hand this difference in reproducing line 25 μm is not of considerable clinical importance according to ADA measures. However, the two groups could effectively reproduce the other two lines (50 μm and 75 μm). These results are similar to another study conducted by Murata et al. 16 which showed that the alginate impression material and type III dental material are compatible to each other and could reproduce the surface details effectively. They explained that result by the presence of specific interaction between alginate impression material and dental stone led to surface roughness of the dental cast. On the other hand, the results of Mariana et al. showed that when increase contact time most of the samples did not reproduce line 50 μm, and did not comply with the ISO standard 2. This difference in results may be due to the difference of the materials brands used in each study, handling of the materials, and the environmental circumstances.

Hardness evaluation of the tested samples in this study showed that the depth of scratches decreased as the contact time increased, group A was significantly different from group B in the depth of the scratches. These findings further support the results of Marquezan et al. 15. These results also match those observed in earlier study conducted by Hiraguchi 13. However, several limitations of this study should be noted; use of digital caliper in measurement instead of profilometer – in spite that digital caliper used in this study produced good reproducibility between repeated readings for each linear measurement, direct comparison with other studies is somewhat difficult because the differences exist in material brands and measuring techniques, and testing only two interval periods with long time in between. Thus, further studies with more accurate devices and multiple interval periods with short time in between are recommended.

Conclusion

Within the limitations of this study, it can be concluded that increased contact time between alginate impression material and type III dental stone:

• Did not affect the dimension stability of stone cast model;

• Decreased richness of details after nine-hour contact (it is not clinically significant according to ADA measures);

• Improved the hardness of the stone cast model after nine-hour contact much more than one-hour contact.

References

1. Revised American National Standards Institute / American Dental Association Specification n. 25 for Dental Gypsum Products. J Am Dent Assoc. 1981;102:351. [ Links ]

2. Revised American National Standards Institute / American Dental Association Specification n. 18. Alginate Impression Materials. 1992.

3. Abass S, Mahmood M, Khalaf B. Effect of microwave irradiation on disinfection, dimensional accuracy, and surface porosity of dental casts. MDJ. 2011;8:177-87.

4. Abdullah MA. Surface detail, compressive strength, and dimensional accuracy of gypsum casts after repeated immersion in hypochlorite solution. J Prosthet Dent. 2006;95:462-8.

5. Ahila S, Subramaniam E. Comparative evaluation of dimensional stability and surface quality of gypsum casts retrieved from disinfected addition silicone impressions at various time intervals: an in vitro study. J Dent Oral Hyg. 2012;4:34-43.

6. Azer SS, Kerby RE, Knobloch LA. Effect of mixing methods on the physical properties of dental stones. J Dent. 2008;36:736-44.

7. Chen SY, Liang WM, Chen FN. Factors affecting the accuracy of elastometric impression materials. J Dent. 2004;32:603-9.

8. Faria AC, Rodrigues RC, Macedo AP, Mattos G, Ribeiro RF. Accuracy of stone casts obtained by different impression materials. Braz Oral Res. 2008;22(4):293-8.

9. Ghahremannezhad HH, Mohamed SE, Stewart GP, Weinberg R. Effects of cyanoacrylates on die stone. J Prosthet Dent. 1983; 49:639-46.

10. Guiraldo RD, Borsato TT, Berger SB, Lopes MB, Gonini Jr A, Sinhoreti MA. Surface detail reproduction and dimensional accuracy of stone models: influence of disinfectant solutions and alginate impression materials. Braz Dent J. 2012;23:417-21.

11. Habib F, Fleischmann LdA, Gama SKC, Araújo TM. Obtenção de modelos ortodônticos. Rev Dent Press Ortodon Ortop Facial. 2007;12:146-56.

12. Hamedi Rad F, Ghaffari T, Safavi SH. In vitro evaluation of a stability of alginate impressions after disinfection by spray and immersion methods. J Dent Res Dent Clin Dent Prospects. 2010;4:130-5.

13. Hiraguchi H, Nakagawa H, Wakashima M, Miyanaga K, Saigo M, Nishiyama M. Effects of disinfecting alginate impressions on the scratch hardness of stone models. Dent Mater J. 2006;25:172-6.

14. Imbery TA, Nehring J, Janus C, Moon PC. Accuracy and dimensional stability of extendedpour and conventional alginate impression materials. J Am Dent Assoc. 2010;141:32-9.

15. Marquezan M, Jurach EM, Guimarães VD, Valentim RG, Nojima LI, Nojima C. Does the contact time of alginate with plaster cast influence its properties? Braz Oral Res. 2012;26:197-201.

16. Murata H, Kawamura M, Hamada T, Chimori H, Nikawa H. Physical properties and compatibility with dental stones of current alginate impression materials. J Oral Rehabil. 2004;31:1115-22.

17. Nallamuthu NA, Braden M, Patel MP. Some aspects of the formulation of alginate dental impression materials – Setting characteristics and mechanical properties. Dent Mater 2012;28:756- 62.

18. Nassar U, Aziz T, Flores-Mir C. Dimensional stability of irreversible hydrocolloid impression materials as a function of pouring time: a systematic review. J Prosthet Dent. 2011;106:126-33.

19. Powers JM, Wataha JC. Dental materials: properties and manipulation. Elsevier Health Sciences; 2014.

20. Rudd KD, Morrow RM, Bange AA. Accurate casts. J Prosthet Dent. 1969;21:545-54.

21. Van Noort R: Introduction to dental materials: introduction to dental materials. Elsevier Health Sciences; 2013.

22. Vandewalle KS, Charlton DG, Schwartz RS, Reagan SE, Koeppen RG. Immersion disinfection of irreversible hydrocolloid impressions with sodium hypochlorite. Part II: effect on gypsum. Int J Prosthodont. 1994;7:315-22.

23. Walker MP, Burckhard J, Mitts DA, Williams KB. Dimensional change over time of extendedstorage alginate impression materials. Angle Orthod. 2010;80:1110-5.

Corresponding author:

Corresponding author:

Mohammed Nasser Alhajj

Department of Oral Rehabilitation

Faculty of Dentistry

Khartoum University

Khartoum, Sudan

E-mail: dr_alhaj@hotmail.com

Received for publication: June 23, 2015

Accepted for publication: July 8, 2015