Services on Demand

Article

Related links

Share

Brazilian Journal of Oral Sciences

On-line version ISSN 1677-3225

Braz. J. Oral Sci. vol.12 n.1 Piracicaba Jan./Mar. 2013

ORIGINAL ARTICLE

Effect of elastomeric ligatures on frictional forces between the archwire and orthodontic bracket

Flávia Ramos Venâncio; Sílvia Amélia Scudeler Vedovello; Carlos Alberto Malanconi Tubel; Viviane Veroni Degan; Adriana Simone Lucato; Letícia Nery Lealdim

Program in Orthodontics, UNIARARAS, Araras, SP, Brazil

ABSTRACT

AIM: To evaluate the frictional force between the archwire and orthodontic bracket generated by elastomeric ligatures with polymer coating (Super slick, TP Orthodontics) and conventional ligatures (Morelli) using two types of insertion techniques.

METHODS: Forty elastomeric ligatures, 20 with polymer coating and 20 conventional, were evaluated. Each type of ligature was separated into two groups (n=10), according to the insertion mode: conventional or crossed (from mesial to distal region crossed in front). To analyze friction, 40 5-cm-long segments of stainless steel orthodontic archwire 0.019" x 0.025" (Morelli) and Edgewise brackets (slot 0.022" x 0.028"; Morelli) were used. Each set (bracket, wire and elastic) was submitted to frictional testing in a universal test machine (Instron 4411) at a crosshead speed of 5 mm/min. Each bracket was moved 5 mm on the wire, with maximum friction and mean friction being recorded by software. Three readouts were taken for each bracket. Data were submitted to two-way ANOVA and Tukey's test (p<0.05).

RESULTS: It was shown that for maximum and mean friction, the polymer-coated ligature did not differ statistically from the conventional type in a dry environment condition. Ligatures placed in crossed mode promoted significantly greater friction than those placed in conventional mode, irrespective of the type of elastomeric ligature.

CONCLUSIONS: Friction depended on the insertion mode, but not on the type of elastomeric ligature.

Keywords: friction, elastomer, orthodontics.

Introduction

Sliding mechanics may be used in cases of tooth extraction, severe crowding, or for problems of discrepancy between the dental arches1, involving movement of brackets along archwires2. However, the disadvantage of using this type of mechanics is the friction generated between the bracket and wire during orthodontic movement3, in which the friction produced at the bracket-wire interface tends to prevent the desired movement.

According to Burrow and Charlotte (2009)4, friction is defined as the force of resistance exerted by the surfaces opposed to the movement. The area of contact is influenced by the roughness and force with which the surfaces are pressed against each other. There are two types of friction, static and kinetic. Static friction is opposed to any application of force, and its magnitude is exactly what it should be to prevent movement between two surfaces, up to the point when it is overcome and movement begins, that is, the force applied is not sufficient to move the object. On the other hand, kinetic friction is opposed to the direction of movement of the object and occurs when the bodies are in motion, that is, kinetic friction is irrelevant during the orthodontic movement of teeth, as continuous movement of the tooth along an arch is rare4. Clinically, dental sliding movement is always preceded by inclination and rotation of the teeth5.

During orthodontic movement, at the stage of alignment, leveling and in sliding mechanics during space closure, the desirable situation is that there should be little or no friction at the bracket-wire interface.

Various factors interfere in friction, but alterations to the elastomeric ligatures deserve attention as they play an important role with regard to friction between the bracket and wire during orthodontic mechanics. A reduction in friction between the bracket and orthodontic wire may be obtained with the use of lubricated elastomeric ligatures, or with alterations in their composition6. Recently, a ligature with polymer coating was launched on the market: Super slick (TP Orthodontics, La Porte, IN, USA), with the purpose of reducing friction, in comparison with conventional ligatures. According to the manufacturer, this ligature is covered with a polymer coating, allowing greater sliding of the wire over this material.

In orthodontic treatment, the most frequently used modes of insertion of elastomeric ligatures are the conventional and crossed types. Ligatures inserted in crossed mode are responsible for a significant increase in frictional force in comparison with other insertion techniques, in a dry and moist medium7. However, little is known about studies of friction generated by elastomeric ligatures with surface alterations using different insertion techniques for retention of the wire to the orthodontic bracket.

It is thus important to study the friction generated by elastomeric ligatures available on the market with the purpose of making orthodontic treatment efficient, fast and inexpensive. According to Leander and Kumar (2011)8, ligature is the most used method for uniting the wire to the bracket, as ligatures are comfortable for the patient, offer fewer risks of causing damage to the mucosa, have better acceptance due to the possibility of choosing colors and increase motivation as regards treatment. Therefore, the aim of this study was to evaluate the frictional force between the archwire and orthodontic bracket generated by elastomeric ligatures coated with polymer (Super slick, TP Orthodontics) and conventional ligatures (Morelli) using two types of insertion techniques.

Material and methods

Fabrication of the Support for the Friction Test

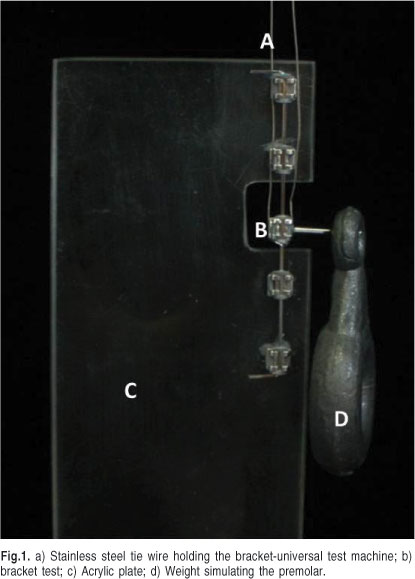

A rectangular acrylic plate (14 cm long by 4 cm wide by 0.5 cm thick), with a groove (1.5 cm deep by 1.2 cm wide) at a distance of 2 cm from one of the extremities was used for the friction test. Initially, the bracket bonding area was abraded with 120 grit abrasive papers (3M, Sumaré, SP, Brazil), then Edgewise brackets, slot 0.022"x 0.028" (Morelli Ltda ref. 10.30.208), were bonded using chemically activated Orthodontic Concise (3M Unitek Corporation, Monrovia, CA, USA) at a distance of 0.8 cm between them and at 1.6 cm in the region of the groove. The distance from the top edges of the brackets to the top extremity of the plate was 0.4 cm (Figure 1).

Before resin polymerization occurred, a stainless steel wire (0.021''x 0.025'') was used to align the brackets and removed after polymerization. After this, a 5-cm-long stainless steel wire segment (0.019"x 0.025"; Morelli; ref. 55.03.014) was inserted into the channel of the brackets, with its two extremities bent to prevent the wire from being displaced from the channels during the friction test.

Test Specimen Fabrication

The extremity of an orthodontic wire 1.00 mm in diameter by 14 mm long (Morelli; 55.06.100) was fixed to the back of the Edgewise orthodontic bracket slot 0.022" x 0.028" (Morelli ref. 10.30.208) with resin Z250 (3M ESPE, St. Paul, MN, USA), light activated with an XL 2500 light-curing unit (3M ESPE), for 20 s, with the bracket slot at 90º in relation to the long axis of the wire. A groove was made 10 mm from the center of the bracket, using a carborundum disc (KG Sorensen, São Paulo, SP, Brazil) in order to place a 100 g weight, simulating the weight of a tooth, in the universal test machine (Figure 2).

For each test specimen, a bracket was used with a stainless steel wire segment 0.019"x 0.025" (Morelli Ltda ref. 55.03.014) and an elastomeric ligature with polymer covering (Super slick, TP Orthodontics, USA) or conventional type (Morelli; ref. 60.03.317). The elastomeric ligatures were inserted in the conventional mode with the elastic tie applicator (Morelli) embracing the mesial and distal winglets of the brackets. In crossed mode they were first placed in the applicator in the same way as before, followed by removal and insertion in the bracket with a Mathieu needle holder (MOCAR, São Paulo, SP, Brasil) from the mesial to distal direction, crossing in the center of the bracket. A total of 40 test specimens were made, 20 for the conventional (10 TP ligatures and 10 Morelli ligatures) and 20 for the crossed technique (10 TP ligatures and10 Morelli ligatures).

Resistance to Friction Test

To analyze friction, the acrylic plate was placed in the universal test machine. For bracket movement, a stainless steel tie wire 0.025mm (Morelli) was used, fixed to one of the extremities in the test machine by means of a vise, and the other extremity fixed on the bracket.

Friction analysis was performed at a crosshead speed of 5 mm/min, the peak and mean values recorded with Bluehill 2.0 software coupled to the test machine. The bracket was moved 5 mm on the wire and the friction evaluated during the run. For each set, 3 repetitions were performed and the mean obtained.

The mean and maximum friction analysis data were submitted to two-way ANOVA (insertion mode and elastomeric ligature) and Tukey's test (p<0.05).

Results

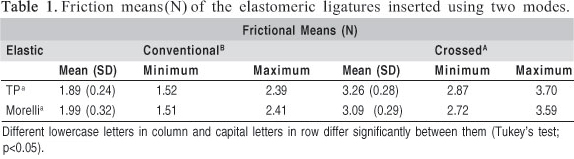

ANOVA showed that for friction there was significant influence of the elastomeric ligature placement mode (p<0.001), but not for elastomeric ligature (p = 0.92) and the interaction between them (p = 0.203). Tukey's test (Table 1) showed that friction of the elastomeric ligatures inserted in the crossed mode was higher in comparison with the conventional mode. There was no statistically significant difference between ligatures for conventional and crossed insertion modes.

Discussion

The technological advancement of elastic materials has increased their applicability in contemporary orthodontic treatments. In order to reduce the friction caused in the bracket/orthodontic archwire/ligature set, ligatures with polymer coating have been introduced on the market. In the present study, they were compared with conventional ligatures, using two insertion modes.

Some factors have been attributed to the increase in friction in orthodontic systems, including the alloy of which the wire is made, wire deflection and thickness, the material of the bracket channel, bracket width, lubrication and the method of ligation9-11.

It is known that the frictional force tends to increase with rectangular cross-section wires in comparison with round wires. Cacciafesta et al. (2003)12 reported higher frictional force with an increase in orthodontic archwire thickness. In ceramic brackets, there is significantly higher friction in comparison with metal or plastic brackets13-15. According to Gandini et al. (2008)16 the metal ligature produces less frictional force in comparison with elastomeric ligatures; however, friction depends on the tying force between the metal ligature and orthodontic archwire, differently from elastomeric ligatures17. Moreover, longer clinical chairtime is required when metal ligatures are used in comparison with elastomeric ligatures.

In order to reduce the friction caused in the bracket/ orthodontic archwire/ ligature set, self-ligating bracket systems have been introduced on the market. In addition to reducing chair time, these devices have shown significantly lower levels of friction in comparison with the system of brackets with conventional ligatures12-14. Nevertheless, these brackets present a higher increase in frictional force when used with wires with rectangular cross sections12.

In this in vitro study, it was verified that the elastomeric ligature with a polymer covering Super slick (TP Orthodontics) promoted similar friction to that of the conventional ligature (Morelli). According to the manufacturer, the products with this technology are made with a polymer coating, insoluble in water, modifying the elastomeric surface, making it extremely smooth, slippery and lubricated. It is likely that the Super slick ligature produced similar friction to that generated by the conventional ligature because the tests in this study were performed in a dry environment condition. On the other hand, some studies have reported that the use of artificial saliva acts as an adhesive17-18, and others - that saliva reduces friction19-20, while a third point of view indicated that saliva makes no difference on the effect of friction21.

According to Magno et al. (2008)22, the polymer coating could be altered during stretching of the ligature with the elastic tie applicators for placement in the bracket, thus modifying the quality of the surface and responsible for the increase in friction. It is known that alterations in the structure of the elastomeric ligature surfaces may vary according to the time and place of storage23, and may affect the polymer covering. Although this is not a variable that is under the orthodontist's control it should be duly considered, because the form of storage, transportation conditions and time may vary from one region to the other, considering the geographic dimension of Brazil and the place of manufacture (USA). The final quality of the elastomeric ligature depends on the raw material, the used technology and quality control. Although the ligatures used in this study were from the same lot, according to Wong (1976)24 ligatures from the same lot may present different properties.

The elastic ligatures from Morelli and TP Orthodontics are synthetic, produced from petroleum-derived polyurethane materials; therefore, they are obtained by means of chemical transformations of coal, petroleum and some vegetable alcohols, which exact composition is not disclosed by the manufacturers.

Thus, in the present study, it was verified that the ligatures placed in the crossed mode were responsible for a significant increase in frictional force between the orthodontic wire and bracket when compared with the conventional insertion technique, irrespective of the used brand. This probably occurred due to the increase of contact surface between the elastomeric ligature and the orthodontic archwire. In this mode of inserting, the elastomeric ligature is crossed over the wire at the points of contact (mesial, distal and center) with the orthodontic archwire surface, whereas in the conventional mode, there are only two points where the ligature touches the wire. Another cause of the increase in friction in this mode of insertion may be the stress generated by stretching, which is transmitted to the orthodontic wire. In this case, when the ligature is stretched, it is tenser and does not return to the original form, and is therefore inserted into the bracket in an extended form so that it will be crossed over it. Thus, the friction increases by the increase in force with which the surfaces are pressed against each other.

It would be recommendable therefore to use elastomeric ligatures or forms of insertion that promote a lower degree of friction in the initial stages of alignment and leveling, as well as in the stages of space closure, so that efficient tooth movement occurs. On the other hand, greater friction would be required during the correction of teeth rotation in the initial stages, when greater contact of the orthodontic wire inside the bracket slot is necessary, in the final stages when torque is necessary25 and in teeth that form part of anchorage units in some orthodontic mechanics.

In summary, the present study demonstrated that no significant difference could be identified between the friction of conventional ligatures and ligatures with polymer coating in a dry environment condition. The crossed mode of inserting the elastomeric ligatures promoted greater friction than the conventional insertion mode, irrespective of the type of ligature.

References

1. Souza RS, Pinto AS, Shimizu RH, Sakima MT, Gandini Junior LG. Avaliação do sistema de forças gerado pela alça T de retração pré-ativada segundo o padrão UNESP-Araraquara. Rev Dent Press Ortod Ortop Facial. 2003; 8: 113-22. [ Links ]

2. Ogata RH, Nanda RS, Duncanson MG, Sinha PK, Currier GF. Frictional resistances in stainless steel bracket-wire combinations with effects of vertical deflections. Am J Orthod Dentofacial Orthop. 1996; 109: 535-42. [ Links ]

3. Chimenti C, Franchi L, Giuseppe MG, Lucci M. Friction of Orthodontic Elastomeric Ligatures with Different Dimensions. Angle Orthod. 2005; 75: 421-25. [ Links ]

4. Burrow SJ, Charlotte NC. Frictional and resistance to sliding in orthodontics: A critical review. Am J Orthod Dentofacial Orthop. 2009; 135: 442-7. [ Links ]

5. Loftus BP, Artun J. A model for evaluating friction during orthodontic tooth movement. Eur J Orthod. 2001; 23: 253-61. [ Links ]

6. Baccetti T, Franchi L. Friction Produced by types of elastomeric ligatures in treatment mechanics with the preajusted appliance. Angle Orthod. 2006; 76: 211-6. [ Links ]

7. Edwards GD, Davies EH, Jones SP. The ex vivo effect of ligation technique on the static frictional resistance of stainless steel brackets and archwires. Br J Orthod. 1995; 22: 145-53. [ Links ]

8. Leander D, Kuramar JK. Comparative evaluation of frictional characteristics of coated low friction ligatures - super slick ties with conventional uncoated ligatures. Indian J Dent Res. 2011; 22: 90-4. [ Links ]

9. Griffiths HS, Sherriff M, Ireland AJ. Resistance to sliding with 3 types of elastomeric modules. Am J Orthod Dentofacial Orthop. 2005; 127: 670-5. [ Links ]

10. Hain M, Dhopatkar A, Rock P. The effect of ligation method on friction in sliding mechanics. Am J Orthod Dentofacial Orthop. 2003; 123: 416-22. [ Links ]

11. Frank CA, Nikolai RJ. A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod Dentofacial Orthop. 1980; 78: 593-609. [ Links ]

12. Cacciafesta V, Sfondrini MF, Ricciardi A, Scribante A, Klersy C, Auricchio F. Evaluation of friction of stainless steel and esthetic self-ligating brackets in various bracket-archwire combinations. Am J Orthod Dentofacial Orthop. 2003; 124: 395-402. [ Links ]

13. Mendes K, Rossouw PE. Friction: validation of manufacturer's claim. Seminars in Orthod. 2003; 9: 236-50. [ Links ]

14. Pithon MM, dos Santos RL, Nascimento LE, Ayres AO, Alviano D, Bolognese AM. Do self-ligating brackets favor greater bacterial aggregation? Braz Dent J. 2011; 10: 3,. 208-12. [ Links ]

15. Keith O, Orth M, Jones SP, Davies EH. The influence o bracket material, ligation force and wear on frictional resistance of orthodontic brackets. Br J Orthod. 1993; 20: 109-15. [ Links ]

16. Gandini P, Orsi L, Bertoncini C, Massironi S, Franchi L. In vitro frictional forces generated by three different ligation methods. Angle Orthod. 2008; 78: 917-21. [ Links ]

17. Khambay B, Millet D, McHugh S. Archwire seating forces produced by different ligation methods and their effect on frictional resistance. Eur J Orthod. 2005; 27: 302-8. [ Links ]

18. Downing A, Mc Cabe JF, Gordon PH. The effect of artificial saliva on the frictional forces between orthodontic brackets and archwire. Br J Orthod. 1995; 22: 41-6. [ Links ]

19. Thorstenson GA, Kusy RP. Effects of ligation type and method on the resistance to sliding of novel orthodontic brackets with second-order angulation in the dry and wet states. Angle Orthod. 2003; 73: 418-30. [ Links ]

20. Baker KL, Nieberg LG, Weimer AD, Hanna M. Frictional changes in force values caused by saliva substitution. Am J Orthod Dentofacial Orthop. 1987; 91: 316-20. [ Links ]

21. Kusy RP, Whitley JQ, Prewitt MJ. Comparison of the frictional coefficients for selected archwire-bracket slot combinations in the dry and wet states. Angle Orthod. 1991; 61: 293-302. [ Links ]

22. Magno AF, Enoki C, Ito IY, Matsumoto, Faria G, Filho PN. In vivo evaluation of the contamination of super slick elastomeric rings by streptococcus mutans in orthodontic patients. Am J Orthod Dentofacial Orthop. 2008; 133: 4-9. [ Links ]

23. Edwards IR, Spary DJ, Rock WP. The effect upon friction of the degradation of orthodontic elastomeric modules. Eur J Orthod. 2012; 34: 618-24. [ Links ]

24. Wong AK. Orthodontic elastic materials. Angle Orthod. 1976, 46: 196205. [ Links ]

25. Ioi H, Yanase Y, Uehara M, Hara A, Nakasima N, Nakasima A. Frictional resistance in plastic preadjusted brackets ligated with low-friction and conventional elastomeric ligatures. Journal of orthodontics 2009; 36: 17-22. [ Links ]

Correspondence:

Correspondence:

Sílvia Amélia Scudeler Vedovello

Avenida Maximiliano Baruto, 500

Araras, SP, Brasil

Phone: +55 19 35431423

E-mail: silviavedovello@gmail.com

Received for publication: November 07, 2012

Accepted: February 25, 2013