Services on Demand

Article

Related links

Share

RSBO (Online)

On-line version ISSN 1984-5685

RSBO (Online) vol.12 n.2 Joinville Apr./Jun. 2015

Original Research Article

Curing depth of a silorane-based resin composite

Guilherme Saintive CardiaI; Sérgio Kiyoshi IshikiriamaI; Ana Flávia Sanches BorgesI; Juliana Fraga Soares BombonattiI; Adilson Yoshio FuruseI; Paulo Afonso Silveira FrancisconiI

I Department of Operative Dentistry, Endodontics and Dental Materials, School of Dentistry of Bauru, University of São Paulo – Bauru – SP – Brazil

ABSTRACT

Introduction: The silorane-based resin appears aiming to minimize the effects of polymerization shrinkage, but other properties must be studied. Objective: To evaluate the polymerization depth of two composites with different organic matrix. Material and methods: 80 cylindrical specimens were prepared using a metallic matrix, with three layers (top, middle and bottom), 1 mm high and 5 mm in diameter. The specimens were divided into eight groups (n = 10) according to the composite resins: Filtek P90 (3M/ESPE); Filtek Z250 (3M/ESPE), light-cured with a LED device with different irradiance and times (600mW/cm2 x 40s, 1000mW/cm2 x 40s, 1000mW/cm2 x 20s; 1400mW/cm2 x 20s). The irradiance was controlled by placing plastic rings coupled to the device's tip. Immediately after polymerization, the specimens' layers were separated and five Knoop microhardness readings (initial hardness) were performed on each one of the four layers (0, 1, 2, and 3 mm). After 7 day storage in water at 37ºC, new readings were performed (final microhardness). The data were analyzed by four-way ANOVA (resin, energy density, depth and time) and Tukey test (α = 0.05). Results: The microhardness decreased with the depth increasing both in the initial and 7 day readings. The hardness increased with the highest power densities. The resin P90 had lower hardness values. Conclusion: The silorane-based resin showed Knoop microhardness values significant smaller than those of methacrylate-based resin in almost all evaluated parameters. However, both presented similar behaviors in relation to the curing depth.

Keywords: resin composites; hardness; siloranebased resins.

Introduction

The properties of light-cured composites resins depend on the curing quality, the composition of resins, and the process used in restorative technique (insertion, curing, finishing and polishing) 1, 2, 7, 16, 24. The photo-activation mainly depends on three factors: 1) minimal light intensity; 2) specific wavelength to activate the photosensitive substance (The photo-initiator present in the resin matrix); 3) irradiation of the material for a given time interval 26. These factors together are important for the reaction reaches the deeper material's layers because the polymerization becomes less effective as it moves away from the irradiated surface, generating damage to the material's properties 1, 2, 7, 13.

Aiming to reduce the polymerization shrinkage, researches have focused on the use of siloranebased monomers 9, 11, 18-23. These resins have demonstrated some desirable properties such as lower polymerization shrinkage than conventional methacrylate-based composite resins 15. Several important clinical properties such as color stability, crack formation, repair techniques, among others, have been evaluated with these low shrinkage resins 6, 10, 11, 14. On the other hand, although the curing depth and its relation with the irradiance of the light sources in conventional methacrylate-based resins have been analyzed 9, 26 in silorane-based resins such parameters have been little evaluated.

The silorane-based resin, as specified by the manufacturer, can be used in larger increments because of the low polymerization shrinkage. This polymerization occurs through the s silorane monomers, which during the polymerization, have open ring-shape structure, so that with the space gained from the opening compensates the volume loss when chemical bonds are formed, differently from the linear reactive groups from methacrylates. In general, the polymerization process through the opening of cationic rings results in a reduced polymerization shrinkage this is given by activation of the acid cation which opens the ring of the oxirane molecule leaving the other cation free to react. The difference between the silorane- and methacrylate-based resins is that the silorane polymerization is given by means of cations, while the polymerization of methacrylates is given by free radicals approaching 18, 23.

Because silorane-based composite is a material with low polymerization shrinkage smaller than 1%, larger increments are recommended for restorations in posterior teeth. However, the studies on the properties as the marginal adaptation 6, 22, sorption and solubility 5, degree of conversion 19 and microleakage 23 indicate that the thickness of these increments may compromise the curing depth.

Although the silorane-based resin is a material with low polymerizat ion shrinkage, further investigation on the curing depth is needed to assess better the thickness of the increments of this material. This study aimed to evaluate the curing depth of two composites, one methacrylate-based and one silorane-based, light-cured by different light irradiances.

Material and methods

The following factors were evaluated: type of resin (2 levels); photoactivation protocol (4 levels); thickness (4 levels); and storage time (2 levels).

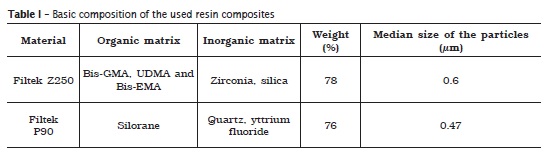

Two different types of composite resin were selected: methacrylate-based micro-hybrid composite (Filtek Z250, 3M Espe, Saint Paul, MN, USA – shade A2) and silorane-based micro-hybrid composite (Filtek P90, 3M Espe, Saint Paul, MN, USA – shade A2) (table I). These resins were light-cured using a LED-based curing unit (Blue Star 3, Microdont, São Paulo, SP, Brazil). The used curing protocols were: 600 mW/cm2 for 40s; 1000 mW/cm2 for 40s; 1000 mW/cm2 for 20s; 1400 mW/cm2 for 20s.

These different power densities were established by connecting 19, 9, and 5-mm plastic rings to the optical fiber's tip so that irradiances of 600, 1000 and 1400 mW/cm2 could be achieved. To assess and certify the irradiance a radiometer (Curing Radiometer Model 100 P/N – 10503, Demetron Research Corporation, Demetron, Orange, CA, USA) was used.

To construct the composite specimens, metallic matrices measuring 1 mm thick were used having a central orifice with 5 mm in diameter (figure 1).

The bottom matrix was placed onto a flat base of bovine dentin with a polyester strip interposed to avoid the adherence of the resin to dentin. Each matrix was filled by a single 1 mm increment (Matrix thickness) with the aid of metal spatula for resins. On the first matrix filled, other polyester strip was positioned, and with the aid of a glass plate, a pressure was exerted up to the leakage of the excess material and obtaining of a smooth and flat surface. On the bottom matrix, other matrix was positioned and its orifice was filled with resin composite using the same operating steps described above. Each specimen was composed by three parts, a lower, middle, and upper one, each one having 1 mm in thickness and 5 mm in diameter (figure 2). On the upper matrix (third), the curing was performed with an angle of 90o, between the tip of curing unit and the matrix.

The matrices of each specimen were separated, and five readings were carried out (load of 50 g for 30 s) in each one of the four surfaces represented by the depths of 0, 1, 2 and 3 mm (initial hardness). The Knoop hardness impressions (initial or immediate hardness) were performed on the lower surface of each disc and on the upper portion of the specimen.

The Knoop hardness values were obtained with a Shimadzu microhardness tester (model HMV- 2000, Kiyoto, Japan). After the recording of the initial hardness, 80 specimens were stored for 7 days in dark bottles containing deionized water at 37ºC. After storage, new microhardness readings were carried out (final hardness).

Data were analyzed by four-way ANOVA having as independent variables the type of resin, curing protocol, thickness, and storage time. Multiple comparisons were analyzed by Tukey test. A global significance level of 5% was adopted.

Results

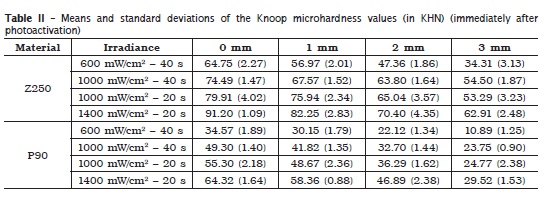

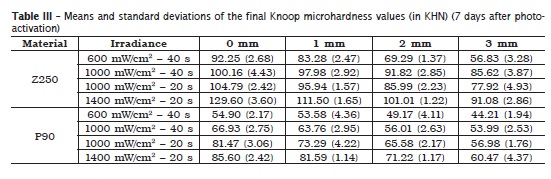

Significant differences were found between the resins (p < 0.05). There was the interaction effect between resin, irradiance, depth and time (p < 0,05). The composite resin P90 had lower mean values of Knoop microhardness than those of Z250. The Knoop microhardness values increased as the irradiance increased. The light-activation protocol with lower values was 600 mW/cm2, and the protocol with the highest microhardness mean values was 1400 mW/cm2. The greater the depth was, the lower the Knoop microhardness values regardless of the group. The final Knoop microhardness values (after 7 days of storage) were statistically significantly higher than those of the init ial Knoop microhardness values (p < 0.05). There was no statistically significant differences in the Knoop microhardness values of the groups photo-activated with the irradiance of 1000 mW/cm2, at different times (20 seconds and 40 seconds) (p > 0.05). The means and standard deviations of Knoop microhardness values obtained immediately after the curing of the specimens is shown in table II. The means and standard deviations of Knoop microhardness values obtained 7 days after the curing of the specimens are shown in table III.

Discussion

Aiming to minimize the characteristic of polymerization shrinkage of the resin composites, changes in the components of the organic matrix have been proposed, highlighting the replacement of the methacrylate-based by the silorane-based monomer, so that, after curing, the composite resins having polymerization shrinkage less than 1% 17. However, the polymerization shrinkage of siloranebased resins must follow the ADA guidelines 1 which suggests that increments with a maximum of 2 mm thickness, so that a better quality of polymerization is obtained, thus improving the degree of conversion, and to minimize the deleterious effects of polymerization shrinkage 3.

As the silorane-based composite resin is a material with low polymerization shrinkage potential, the manufacturer suggests its use at single increments over 2 mm thick. However, clinically, larger increments could be responsible for failures in restorations and secondary caries, particularly in the cervical region and class II preparations, among other problems. Another factor that could be compromised by the use of larger increments would be the curing depth, as it depends on the passage of light across the thickness of the composite resin increment. It is known that a proper polymerization is a crucial factor in obtaining physical properties and for the clinical performance of composite resin restorations 19.

The microhardness va lues found a f ter microhardness testing showed that siloranebased resin obtained statistically lower values than those found with the methacrylate-based resins for all protocols. The decrease in the depth of polymerization of silorane-based compared with methacrylate-based resin may be related to the chemical differences of the monomer and to differences in the type and distribution of inorganic particles. The degree of conversion of methacrylatebased resins is measured by the amount of double bonds between carbon molecules existing after the completion of polymerization 26. However, in silorane-based resins these bonds do not exist, then another type of test should be applied to assess the degree of conversion of these resins. Palin et al. 20 performed a specific test to evaluate the degree of conversion and obtained that the silorane based resin showed statistically lower values than those of the methacrylate-based resin 20, which corroborates the results of this study.

According to the ADA 1, the hardness recommended for the resin composite is of 55 kg/mm2 in Knoop hardness. When evaluating the silorane-based resin hardness, the values obtained in specimens undergoing high irradiance after one week of storage could be considered satisfactory according to the ADA's recommendation. However, in the other protocols observed, the values obtained for the silorane-based resins were lower than those recommended. Additionally, in all photoactivation protocols, the hardness values were statistically lower than those found for the methacrylate-based resin, regardless of evaluation depth.

In an attempt to increase the degree of conversion during polymerization, the increasing of the irradiance has been recommended 12, 21. Even with this strategy, it is noteworthy noting that the silorane-based resin requires a minimum curing time of 20 seconds due to the cumulative character of the initiator system of this resin that cannot be offset by higher intensities, because it generates heat which plays a key role in this reaction, favoring the acceleration of the opening of the rings 18.

In the comparisons between the mean Knoop hardness values analyzed at both times (initial and 7 days), it was found that all samples exhibited an increase in hardness. This fact may have occurred because the resins, after completion of photoactivation, undergo a complementary process of polymerization and reach a greater numbers of crosslinking and higher degree of conversion by one week and consequently improve its mechanical properties 4, 25, 27. This behavior can be observed in the results of both composites evaluated.

Conclusion

Based on the microhardness tests, the siloranebase resin showed smaller hardness values than those of methacrylate-based resin. The increasing in irradiance resulted in higher hardness values for both resins. Acceptable hardness values were found in methacrylate-based resin at all depths and irradiance.

References

1. American Dental Association. Council on dental materials. Instruments and equipment. Visible lightcured composites and activating units. J Am Dent Assoc. 1985;110(1):100-3. [ Links ]

2. Anusavice JK. Phillips: materiais dentários 10. ed. Rio de Janeiro: Guanabara Koogan; 1998.

3. Bayne SC, Heymann HO, Swift Jr EJ. Update on dental composite restorations. J Am Dent Assoc. 1994 Jun;125(6):687-701.

4. Blankenau RJ, Kelsey WP, Cavel WT, Blankenau P. Wavelength and intensity of seven systems for visible light-curing composite resins: a comparison study. J Am Dent Assoc. 1983;106(4):471-4.

5. Boaro LC, Gonçalves F, Guimarães TC, Ferracane JL, Pfeifer CS, Braga RR. Sorption, solubility, shrinkage and mechanical properties of "lowshrinkage" commercial resin composites. Dent Mater. 2013 Apr;29(4):398-404.

6. Boroujeni PM, Mousavinasab SM, Hasanli E. Effect of configuration factor on gap formation in hybrid composite resin, low-shrinkage composite resin and resin-modified glass ionomer. J Investig Clin Dent. 2015 May;6(2):156-60.

7. Bowen RL. Properties of a silica-reinforced polymer for dental restorations. J Am Dent Assoc. 1963;66:57-64.

8. Carvalho AA, Moreira FC, Fonseca RB, Soares CJ, Franco EB, Souza JB et al. Effect of light sources and curing mode techniques on sorption, solubility and biaxial flexural strength of a composite resin. J Appl Oral Sci. 2012 Mar-Apr;20(2):246-52.

9. Claro-Pereira D, Sampaio-Maia B, Ferreira C, Rodrigues A, Melo LF, Vasconcelos MR. In situ evaluation of a new silorane-based composite resin's bioadhesion properties. Dent Mater. 2011 Dec;27(12):1238-45.

10. Cunha LF, Santana LOC, Baratto SSP, Mondelli J, Haragushiku GA, Gonzaga CC et al. Staining susceptibility of methacrylate and silorane-based materials: influence of resin type and storage time. RSBO. 2013 Apr-Jun;10(2):161-6.

11. Cunha LF, Dziedzic DSM, Nascimento BM, Baratto SSP, Gonzaga CC, Furuse AY et al. Influence of different surface treatments on the shear bond strength of a methacrylate resin composite repaired with silorane-based resin. RSBO. 2013 Jul-Sep;10(3):240-4.

12. Davidson CL, de Gee AJ. Light-curing units, polymerization, and clinical implications. J Adhes Dent. 2000;2(3):167-73.

13. Dunn WJ, Bush AC. A compa r ison of polymerization by light-emitting diode and halogenbased light-curing units. J Am Dent Assoc. 2002;133(3):335-41.

14. Dziedizic DSM, al Sayd S, Cunha LF, Santana LOC, Gonzaga CC, Furuse AY. Repair on siloranebased composite. RSBO. 2014 Jan-Mar;11(1): 19-27.

15. Eick JD, Kostoryz EL, Rozzi SM, Jacobs DW, Oxman JD, Chappelow CC et al. In vitro biocompatibility of oxirane/polyol dental composites with promising physical properties. Dent Mater. 2002;18:413-21.

16. Fan PL, Schumacher RM, Azzolin K, Geary R, Eichmiller FC. Curing-light intensity and depth of cure of resin-based composites tested according to international standards. J Am Dent Assoc. 2002;133(4):429-34.

17. Heo YJ, Lee GH, Park JK, Ro JH, García- Godoy F, Kim HI et al. Effect of energy density on low-shrinkage composite resins: diode-pumped solid state laser versus quartz-tungsten-halogen light-curing unit. Photomed Laser Surg. 2013 Jan;31(1):28-35.

18. I l ie N, Hickel R. Si lorane-based dental composite: behavior and abilities. Dent Mater J. 2006 Sep;25(3):445-54.

19. Kusgoz A, Ülker M, Yesilyurt C, Yoldas OH, Ozil M, Tanriver M. Silorane-based composite: depth of cure, surface hardness, degree of conversion, and cervical microleakage in class II cavities. J Esthet Restor Dent. 2011 Oct;23(5):324-35.

20. Palin WM, Fleming GJ, Nathwani H, Burke FJ, Randall RC. In vitro cuspal def lection and microleakage of maxillary premolars restored with novel low shrink dental composites. Dent Mater. 2005 Apr;21(4):324-35.

21. Pilo R, Oelgiesser D, Cardash HS. A survey of output intensity and potential for depth of cure among light-curing units in clinical use. J Dent. 1999;27(3):235-41.

22. Santos PJ, Silva MS, Alonso RC, D'Alpino PH. Hydrolytic degradation of silorane- and methacrylatebased composite restorations: evaluation of push-out strength and marginal adaptation. Acta Odontol Scand. 2013 Sep;71(5):1273-9.

23. Shafiei F, Akbarian S. The effect of LED curing mode on microleakage of class V cavity restored by silorane-based composite. Acta Odontol Scand. 2013 Sep;71(5):1162-7.

24. Tjan AH, Chan CA. The polishability of posterior composites. J Prosthet Dent. 1989;61(2):138-46.

25. Von Fraunhofer JA. The surface hardness of polymeric restorative materials. Br Dent J. 1971;130(6):43-5.

26. Watts DC. Reaction kinetics and mechanics in photo-polymerised networks. Dent Mater. 2005;21:27-35.

27. Watts DC, McNaughton V, Grant AA. The development of surface hardness in visible l i ght-cured poster ior composites. J Dent . 1986;14(4):169-74.

Correspondence:

Correspondence:

Sérgio Kiyoshi Ishikiriama

Departamento de Dentística, Endodontia e Materiais Odontológicos

Faculdade de Odontologia de Bauru

Universidade de São Paulo

Alameda Octávio Pinheiro Brisolla, 9-75

CEP 17012-901 – Bauru – SP – Brasil

E-mail: serginho@usp.br

Received for publication: April 12, 2015

Accepted: April 28, 2015